-

Posts

34 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Sumter SC USA

Recent Profile Visitors

382 profile views

-

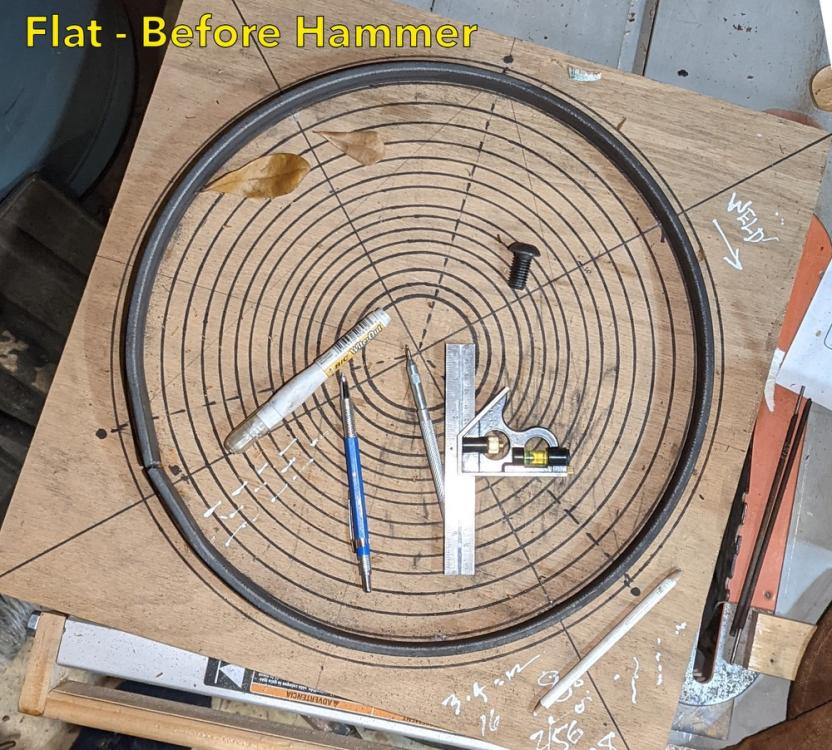

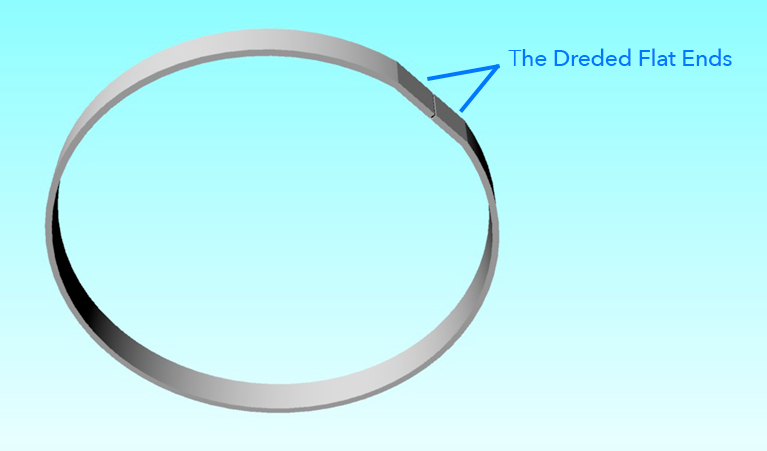

Found one simpler approach - Sometimes it IS advisable to put the CART BEFORE THE HORSE. Moving along with the current project, I have found it time consuming and frustrating to PRE-bend the ends of the 47-1/2 inch flatbar/workpiece in the vise-held radius fixture. Instead, I thought about perhaps correcting the flats AFTER rolling the circle (I am certain that many of you already thought of that)... and it works really well, and fast. These photos show the before and after of the segment in question - the whiteout pen (wonderful metal marker by the way) is kind of pointing at the area.

-

Phillip-SC started following Scott NC

-

Yes! Please do share that, with my THANKS! Are you thinking to simply slide in a prebent segment between rollers, then lay the ends of my workpiece over that? I think that would work -- How cool! The adjustment of center roller position is done with a little builtin 4 ton hydraulic cyllinder, so that is easily doable. If my guess is wrong, I bet it's even better.

-

Yes. Thank you both. It is now long established (over 50 hoops so far) that my 15 inch circles, using the midline as a reference, start out as 47.25 in pieces of flatbar. I'm too far along on this project to change the rolls. The good news is I will definitely make the changes on the roller machine next time. And - more good news - while installing some of the beginning work over in Wilmington NC (3 hours away), neighbors have requested to be "next on the list" for the same or similar design. Yay! Thanks so much for your help.

-

Phillip-SC changed their profile photo

-

That is correct, they are not adjustable. However, in my next (?) similar project, I will definitely use your idea; the two bottom rolls are the drive rolls on this roller, driven by a hand crank and heavy sprocket chain on the other side of the machine. I can probably add the right size ring over each roller and use a keyway or countersunk bolt in each to maintain the transfer of crank power? Great idea - Thanks

-

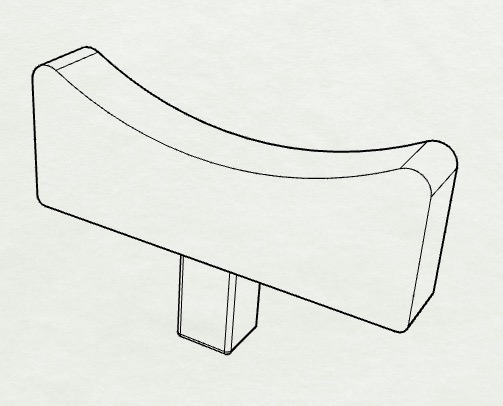

SOLVED ... for now. Thank you to all who responded! I just went ahead and made a rough but durable tool from scrap 1 inch thick steel to fit either a heavy vise or hardy hole. The radius varies from about 5-1/2 to 8 inches, and I treaded a hole for a removable bolt/stop at the "sweet spot" for this particular project. Seems to do a good job for now.

-

All the great input and ideas are appreciated, but in the interests of time (or more precisely, getting my procrastinating hind parts started on this big project) a simple curved cradle for the hardy hole will be employed for now. I'll just hammer both ends of the flatbar into a nice 6-inch curve - assuming a little spring back - and see what happens. Not giving up the quest for something much more consistent though.

-

Thank you both, GeorgeN.M. and Glenn, those are both very good ideas, as my main target is consistency (reproduciable quality) first and time savings second. Obviously, material savings is important, too. I do pefer to work COLD in this project, so if Glenn's idea is used, I need to figure out the proper smaller radius for the tool if I go that route, due to the spring-back in bending that we are all familiar with. It is a 7-1/2 radius (15-inch diameter of course), so I'll see what happens with 6-inch radius tool to begin. Thanks!

-

Thanks, George. As noted above, I really need to economise on the material by getting five circles from each 20-foot length of flatbar; I cannot afford to cut off any excess, since each circle starts with a 47-1/4 inch length. May as well say 4 feet. Input definitely appreciated though. Thank you, Scott. My rollers are not configured like sliprolls are. That is, only ONE of the 3 rolls can be moved. Thus, there is simply no way to accomplish a smooth bend if the entire length of the workpiece (and no excess in length) is to be formed. In fact, the best this machine can do yields a 3-inch flat (see photos). Still working on it.

-

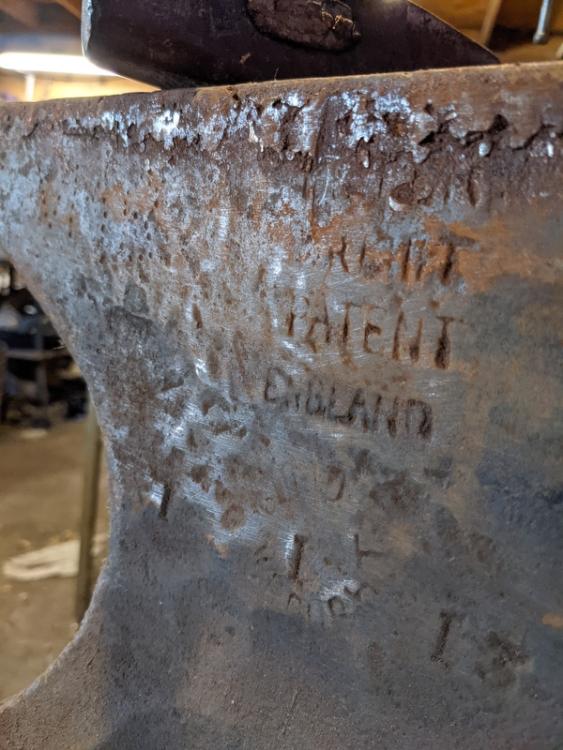

Are you saying to go ahead and weld the hoop together with the flats, then put it back onto the roller? I will give it go, but have doubts about my skills. That is a stroke of genius for sure -- Thanks! Those radii seem a bit small on my anvil though, like maybe for 8 inches diameter at most. It's just around 120 pounds (no clue of the actual brand (anybody?) or weight).

-

No doubt everyone on this forum is VERY familiar with the dreded flat spot created in large cold formed steel circles (and scrolls, too). On a short run basis, this is no big deal, since you can hammer a nice short curve in the ends of the flatbar or roundbar workpiece. But what if you are making a ZILLION (well, 90 anyway) CIRCLES?? I find myself needing to make over ninety 15-inch circles from 1-1/2" x 1/4" steel flatbar, and that is a good thing, but I would like to save time on the ends of my 47 inch workpieces if possible. Has anyone here come up with a quick and consistent way of prebending the ends of what will become a hoop, that they would like to share? I've tried pressing into a small curved space and that does not seem to be the ticket to success. I would be great to have a swage block with a large radius, using a quick hammer blow, but that isn't available. Thanks for any solutions or hints to getting that curve onto the ends of the flatbar. PLEASE NOTE: Often times the flat parts are simply made to overlap, and then the excess is trimmed away, BUT my workpiece is just under 4 feet in length and that allows 5 circles to be taken from a standard 20-foot "stick" of flatbar. Thus, using the trim technique would lead to a lot of wasted raw materials. Thanks for any input!

-

Where on Earth kind I find this fence bracket!?

Phillip-SC replied to Phillip-SC's topic in Problem Solving

Thanks! Yes, they are 3 inches longways and accommodate 1-1/2 inch flatbar top rails. I did not go into specifics because of being dumbfounded -- in general -- that any such brackets are apparently impossible to find from suppliers. Still pretty much amazed at that. -

Where on Earth kind I find this fence bracket!?

Phillip-SC replied to Phillip-SC's topic in Problem Solving

Thanks again to all! I went ahead with the pattern idea. Test pieces using 11 gauge turned out pretty well, so a little thicker will work. Note my fine "CNC" machine (masonite lasts a long time and 6 legal size clipboards are about 12USD)! -

Where on Earth kind I find this fence bracket!?

Phillip-SC replied to Phillip-SC's topic in Problem Solving

Whoops! I goofed. You mean the material that will be bent into the part for the bracket. Duh. I got now. That material will be 1/8 inch thick sheet steel.. Thanks again.