Les L

Members-

Posts

855 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Les L

-

Mercier, As Billy Bones stated, Louisiana Metalsmiths Association (LAMA) and GCBA is a great place to start. I am a member of LAMA, we hold a meeting monthly, you will meet a lot of great people that are eager to help you learn.

-

Cannon Cocker, congratulations on getting the pieces of family history. I was lucky and got my grandfathers blower and my uncles blower and forge earlier this year. I found some 3” aluminum flex vent at the big box store to connect the blower to the forge that works great

-

Nice job on all 3

-

Make sure the bolt is not bottoming out in the hole, or the threads are only cut part way if the hole is deeper than the bolt. If you have enough threads and they are messed up partway down it may just be dirt or rust at the depth the bolt has been sitting. Take a tap and clean the threads.

-

Chris, i had the “pleasure” to use a set of those hammer eye tongs last weekend. They work great, but take some practice, especially on larger round stock. Once you start working the stock and get a flat spot or the eye punched it’s no problem handling the material. First time you try them is like using chop sticks in your non dominant hand

-

Finally figured out this anvil stamp

Les L replied to Hellcat's topic in Anvils, Swage Blocks, and Mandrels

Hay Budden made anvils for the hardware store W.B.B&Co. Louisville, Ky. The name of the store changed 3 times from 1840 -1907, W.B Belknap& Co. was 1860-1880. -

I would take one of the doubled washers out and see if the handles clears it. The previous owner may have placed two as spacers because they replaced the bolt and it is a little too long, if so trim the bolt to the correct length.

-

Eye- and mind bending events on my Puukko horizon

Les L replied to templehound's topic in Knife Making

Beautiful work, as always. -

Latticino, You need neighbors like I have, the one next door came over yesterday evening and showed me a picture of an old coal forge for sale $650 and wanted to know if he could buy it for me as a gift. I think he is more excited about me starting to do blacksmithing than I am.

-

Because they like the color

-

What did you do in the shop today?

Les L replied to Mark Ling's topic in Blacksmithing, General Discussion

I am sure it is, I can only imagine at this point. Maybe in the near future when I have time to travel I may be able to show up somewhere she is working. -

What did you do in the shop today?

Les L replied to Mark Ling's topic in Blacksmithing, General Discussion

Jennifer, For some reason all your response , and pictures, didn't come through on my end until now. I wish I was in your area so I could come see some of your demos. I learn so much from your videos that I can't imagine what I could learn being there in person and asking questions about steps I didn't fully understand. I understand about shop lingo being different in different areas, I work for a company that has offices in 4 different states, almost every tool has a different name in each area, much less each state. I'm like Frosty and most others, one name so everyone knows what the person is talking about. -

What did you do in the shop today?

Les L replied to Mark Ling's topic in Blacksmithing, General Discussion

Trig shucks! Now my eggs are really scrambled, but I'm still hanging in and learning. Chris, That was two days, 10 hrs. the first and 11 the second. We had some lost time the first day waiting for all 8 to complete each step, but the second day was almost non stop. Each person performed one step at a time then swapped and your partner did the same step, it would take two to three heats to do each step and swapping out with your partner as striker allowed you to rest from swinging the maul. It wasn't bad at all, do not hesitate to do it if you have the chance. I don't know what the price for the class is if you go to his shop compared to what our club set up, but it wasn't bad. PM me and I can give you information on the instructor so you can check into it if interested Your Blacksmith club may want to check into setting up a class like ours did. -

WFM,, Make a three legged stand for the anvil with wheels on the back two legs, that just touch the ground like on a hand cart, weld a horizontal piece of pipe on the front leg below the anvil then stick a pipe or pry bar in it, lift and roll where you need it. I would recommend using pipe for the handle so you can drill through both and pin it to ensure it doesn't pull out while moving, especially if you have to pull it. The larger the tires, the easier it will move, just don't get so large they get in your way of working.

-

What did you do in the shop today?

Les L replied to Mark Ling's topic in Blacksmithing, General Discussion

JHCC, Just when I thought I might be starting to learn something you threw in trigonometry! Just joking, thanks for the help, or maybe warning. I can see I'll still be walking around lost for awhile, but I learn something new every day, thanks to all on this site. The press is looking great! bet you can't wait to stick hot iron in it. -

What did you do in the shop today?

Les L replied to Mark Ling's topic in Blacksmithing, General Discussion

Frosty, Thanks for the complements and explaining the proper names of the tools. I know what they are used for, but can't always remember the name. I've read and heard so much in the last few months i'ts all running together. I believe in using the proper/common term so please continue to correct me when I mess up (you notice I didn't say if I mess up?) -

What did you do in the shop today?

Les L replied to Mark Ling's topic in Blacksmithing, General Discussion

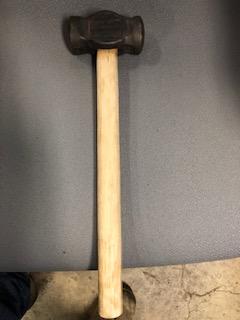

Frosty, I agree, they want to learn, listen and attempt to duplicate, are not afraid to ask what they did wrong and need to do to correct it and are very polite. We made our rounding hammer first. I don't know if I can identify the instructor on this forum, but most will recognize the style and know who he was. Then made our hot cut hardy (may be wrong name, please correct if needed, he just called it hot cut) Then made a set hammer, I still have a little dressing to do. Then a handled hot cut, we used our set hammer to set the shoulders -

What did you do in the shop today?

Les L replied to Mark Ling's topic in Blacksmithing, General Discussion

I surprised myself that I held up over the two days. Cancer treatment two years ago took a lot out of me. I had a young man 40 yrs younger than me for a partner and he kept asking “how do you hit like that”? I was able to show him technique to increase power and save energy. He wanted to learn and would listen, big change from most of the young people I’ve worked with recently. Will sen more pictures in a few minutes. -

What did you do in the shop today?

Les L replied to Mark Ling's topic in Blacksmithing, General Discussion

Chris, Thanks for the complement, The class was worth every minute, especially for someone just starting out. I learned so much, so quick, that it can't be explained and we had fun the entire time. The cost was very reasonable and the value of the tools were about 5 times the cost of the class, experience, can't put a price tag on it. -

nice haul!

-

What did you do in the shop today?

Les L replied to Mark Ling's topic in Blacksmithing, General Discussion

I took a hammer and tool making class this weekend that our blacksmith organization set up for members . There were eight of us in the class, we had a great time and learned a lot. Two 11 hr days and didn't have time to do all we wanted, but it was worth every minute. everything was done by hand, no power equipment except for cutting the stock to size. First thing I learned was it's been a while since I swung a 12# maul all day. -

Daswulf, Thanks for the heads up on the wheel springing when cut.

-

That’s a beauty, congratulations on the find

-

Thank you

-

Cleaning up behind my Dad's shop and found the iron tire from an old 4' wagon wheel I found on the Pine Ridge Indian reservation, outside Wanblee S.D. in the early 70's when I was working for a custom combiner. It was the complete wheel then, but all the wood has rotted away since. Is this wrought iron, how do I tell? 1 3/4 x 1/2