Les L

Members-

Posts

855 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Les L

-

Thomas, Here's a picture of a reverse draft I built. There's a plate welded inside from the firebox to the opposite end, with a small opening for the smoke to come to the top and back over the meat. Great for low and slow cooking.

-

I thought about the paint, but it took around 100 years to get this look, and it didn't seem right to me to paint it, so I went with BLO. I can always paint it in the future, if I change my mind.

-

Livonia, outside Baton Rouge.

-

I used the 50/50 mix to free up the engine in a Bronco that I picked up a couple of years ago. It had sat parked in a field for 20 years, couldn't turn it over with a 3' cheater on the breaker bar. I filled all the cylinders, let it set for a week and turned it over with an 18" breaker bar. Didn't think about using it to clean the old solid grease off, I'll mix some up tonight.

-

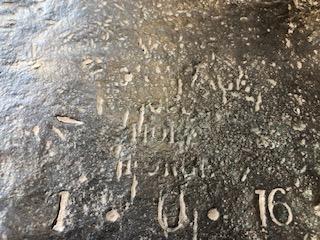

It was a lot of fun, 100 year old crud doesn't want to come off! The other one is worse, I've been squirting degreaser on it every day for a week and it hasn't made a difference yet.

-

Thanks to all for the kind words and encouragement. I was able to identify the champion blower was my grandfather's and the forge and Canedy-Otto blower was my uncles. I've decided to hook the champion to the forge and use the hammer I found with them to forge my first item.

-

I got the 400 cleaned up and oiled and put a handle on one of the cross peen hammers I found in the barn with the blowers.

-

Dad and Frosty, thanks I can’t wait to make my stand and put it to work Ben, that’s a fine piece of equipment. I picked mine out of the trash 35 years ago, no motor or pulley, mounted an old motor and step pulley on it, set it on the slowest setting and been using it since without charging anything. Never burned a drill bit and drill most dry.

-

While getting gas I saw a retired farmer, that I hadn't seen in a couple of years, and while talking I mentioned I was working on building my blacksmith shop. He said that he had an old anvil that his brother had given him before he died, "but I can't get rid", stopped and then said "you knew him didn't you? I said yes, I knew him and he said "when can you come by my house? I almost beat him there. It has some edge damage where someone cut with a torch on it, but has 70-80% rebound, weighs 128# as stamped.

-

MeatMan, You can cut 11.5 inches off the chisel end and weld it on the other to get your 31 inches.

-

I would hard pipe it, threaded or compression fittings, to a point far enough away from the forge to ensure that it will not get hot then use the proper propane hose and connections to the tank.

-

Irondragon, Thanks for the pointers, I appreciate all the information everyone is providing . I cleaned the dirt daubers and cob webs out of both fan housings before trying to turn them. Pulled the top cover off the 400, there was a light film of oil on all gears and they were in great shape. I'll check the grease on the bearings and add the oil to it this weekend. Currently researching the maintenance on them now. The Canedy Otto was full of 90 weight, I had to lay it down to bring it home and oil ran out. I'll work on it after I finish with the 400 and get it hooked up to the forge.

-

That's the best part of travelling, unfortunately my travel for work doesn't give me the time to visit, but that will change in a few months when it will be for my enjoyment and I will be setting the schedules. I hope to be able to meet and visit with some of you on IFI in the near future.

-

I only knew my paternal grandparents. Grandfather raised 10 children with his forge, a grist mill and 40 acres. Dad was in the Military so I wasn't able to spend much time with my grandparents. I spent the summer with them in the early 70's, granddad was 85, I was 13-14, he was still farming and had about 20 head of cattle. We were up every morning before daylight, I pumped water into trough while he fed the cattle and grandmother milked the cow, then back home for breakfast, fresh eggs, milk and home made bread, butter and preserves, so we could eat and get into the field at sunrise to pick corn all day by hand to put into the crib for the cattle's winter feed. Best summer I ever had, but I've always been told I wasn't very smart.

-

Frosty, Thanks for the help. Everything is there except the handles, I'll work on cleaning them up and making handles this weekend. Work has me on the road most of this week.

-

Barn find I was given two blowers and a forge that were my grandfather's and uncle's. I do not know who which one owned which blower or the forge. They have been stored in a barn for over 50 years. Both turn great, are very smooth with no grinding noise, I can turn both by hand using the end of the shaft, but both are missing the counterbalanced crank handles. If anyone knows of replacement parts for sale or can provide the crank length and weight of the counterbalance so I can build them I would appreciate it. I would prefer to have original manufacturer's parts for them, but will make them if original is not available. Thanks, Les P.S. If the pictures are too large please point me towards the directions to resize them, I tried to find them to check size, but I am not very good on a computer and couldn't find it. .

-

Frosty, Your right , there are worse honey do's, like the painting she has had me doing. Lou, One of the earliest things I can remember about my grandfather is turning the crank on that forge, it wasn't lit, but he sure got mad when I had it cranked up so high I blew all the coal out of it, I had it sounding like an air raid siren. We were living out of state when his shop was torn down and I've been wondering what happened to the forge for the last 50 years, I finally asked the right person and will be able to get it. I've been gathering metal for years, most of it is mild steel, but I have been able to get some high carbon in the stack to make some tools with lately.

-

Frosty Thanks for the reply encouragement and information. The shops a few hundred feet from any other structure and well ventilated. I’m used to working in the heat doing farm work and welding on live natural gas lines but reminders are always welcome. It’s what we call being your brothers keeper. I have the co monitors on my list of needed equipment for the shop. Daswulf you wouldn’t believe the ideas she can come up with if she buys a book with projects in it I’ll be working 7/12 again

-

Hello everyone, I've ben reading information on here for the last couple of month's. I want to thank all of you for the information you provide, it has helped me in making a decision on what I will be doing in the near future and I have learned a lot about the tools I will need, the current value of them and what I will need to set up my shop and get started. I am just getting started with blacksmithing, currently gathering tools and expanding my current shop to turn it into my smithy. I have been a welder/fabricator for the 40+ years, always interested in blacksmithing, my Grandfather and one of my uncles were blacksmiths, but I did not have/take the time to get started in it, but all the excuses will be gone in the next few months when I won't have to head to work at 4:30 every morning. After I showed my wife some pictures of the wonderful work everyone on this site does I think she is more excited than me for me to get started heating and beating iron. I have located my Grandfather's and uncle's forges and will pick them up in the next couple of weeks, I have managed to acquire a Fisher and a Vulcan anvil, a post vise, and several pair of tongs so far (TPAAAT works good, my wife says I'm scrounging, but I was able to show her it is an official technique). I'll post pictures of them in the tool section after I finish cleaning everything up.