-

Posts

2,506 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by BillyBones

-

Testing hammer accuracy

BillyBones replied to QbBlacksmith's topic in Blacksmithing, General Discussion

Had to dig a punch out of my slack tub the other day. Armpit deep in the water and what was on the bottom, i am not sure i really want to know what it is. Grandma used to ring the chickens necks. She would grab one by the neck from the back between her middle and ring finger lift it up and with a quick snap of her arm break the neck. Sometime the head would come off in her hand but if they ran around it was usually with their head flopping around to one side. Jumped out of a HEMTT one day at NTC almost on top of a sidewinder, he made a sort of half strike kind of thing then winded (is the what a side winder does, i know they cant run) away fast. Scared him way more than me. -

What did you do in the shop today?

BillyBones replied to Mark Ling's topic in Blacksmithing, General Discussion

I was leaning towards cistern myself. Watched a video of john Switzer (?) at the Black Bear Forge making a flower. So here is my take on one. -

What did you do in the shop today?

BillyBones replied to Mark Ling's topic in Blacksmithing, General Discussion

I was thinking a septic tank or cistern. It was in the back and all my utilities come in from the front. That does not mean that they always did though. My mom went across my back yard where we are digging with a metal detector, the house has been here for about 100 years so she was curious, she totally missed this huge piece of iron. I found a nickel, a new nickel...they make it look so easy on the videos. See why they get excited about finding a button. -

What did you do in the shop today?

BillyBones replied to Mark Ling's topic in Blacksmithing, General Discussion

Has anyone bought new steel recently? How the price has gone up. Almost doubled. Anyway i needed new steel for an up coming project. It will be porch railing. The existing railing is wood with just square spindles. I will take out the middle three and put in an iron center piece. Then every 3rd spindle will come out and be replaced with iron. Or at least that is the plan. So yesterday i spent working on the process and making a couple scrolling jigs. A total of 28 scrolls will be needed. The center piece has a tenon that will go through the top piece, it will be threaded and i am going to make something like a blacksmiths diamond that will be tapped to go on top. The bottom will have a finial that will bolt to the lower rail. Anyway here is my lay out, one side of the bottom is missing and the scroll is not right, just laid it there to get an idea of what they will look like. Above to the right is one of my jigs cooling off. Oh, this is one of the center pieces. The spindles will be just simple twisted bars. Also been working on getting my deck built. Man what a pain 8 holes, 14" around and 34" deep, by hand. Almost a yard of concrteBut while digging found this. What to do with it? That 18 on the bottom (top of the photo) is how big around it is, 18". JHCC, i am still trying to get that upset square corner down, almost there but not quite. I can get the nice sharp corner but i end up narrowing it down. Just have to keep trying i know eventually i will get it. Ted, really nice flag holder there. My flag pole is an old tent pole, one of the telescoping kind. -

Testing hammer accuracy

BillyBones replied to QbBlacksmith's topic in Blacksmithing, General Discussion

There is a small gap at the back there, but it only goes maybe 1/4" or so into the eye. If i were to use it i would definitely do like an epoxy fill in that spot. He is a true artist when it comes to wood working and epoxy but he could use some work on his hefting skills. I made one of his friends an axe, that is how i got my longbow. He was looking more for a hawk than an axe with a rounded eye though. Anyway he took the axe i made and handled it for me before giving it back for the hawk i made. Guy made a really nice osage handle for it but when he wedged it he put about 8 wedges around the wood and not into the wood. I got a pretty good chuckle out of that. -

Testing hammer accuracy

BillyBones replied to QbBlacksmith's topic in Blacksmithing, General Discussion

-

What did you do in the shop today?

BillyBones replied to Mark Ling's topic in Blacksmithing, General Discussion

Tried out that back support i made for my anvil. Worked quite nicely making the first of what will be a few turning wrenches. The first one i failed is lying next to the one i made yesterday. A little wider than i was going for but that can be either fixed or just make another slightly smaller. -

What did you do in the shop today?

BillyBones replied to Mark Ling's topic in Blacksmithing, General Discussion

Frosty, either i cannot visualize what you are saying or maybe you misinterpret what i am getting at. I need to draw out the nub but keep the back from offsetting on the vice jaw. So i will be hammering straight (more or less) down on to the nub. The little notch at the back is what i do not want. After going back to read your post again i have to ask, are you thinking i am doing an animal head? I am making a turning wrench, but i do know the tool you are talking about i believe and that may work also. So i do not have one, off of work tomorrow, cant think of a reason not to make one and give it a try. I am going to need more than one wrench anyway why not try different methods and find what works best for me. It also now does not look as a failed wrench and could be salvaged into an animal head, so i need the bridge anyway now. -

Testing hammer accuracy

BillyBones replied to QbBlacksmith's topic in Blacksmithing, General Discussion

I have thought about it but he gave me the hatchet as a gift. I have others so i just let it hang on my wall in the shop. -

What did you do in the shop today?

BillyBones replied to Mark Ling's topic in Blacksmithing, General Discussion

I have an upcoming project that is going to have a lot of bends and some scrolling coming up. Well i need a decent turning wrench instead of using a pair of pliers or something and decided to make one. Well off to the internet i go. Seemed that Mark Asprey had a way of doing it that was quite easy to draw out the little nub. However i missed the part where he had a piece supporting the back of the piece. So here i am now with a coule hours before i have to go to work to day and decided to go out and make me a support. Justa piece of angle with another welded on to hopefully prevent this. -

Testing hammer accuracy

BillyBones replied to QbBlacksmith's topic in Blacksmithing, General Discussion

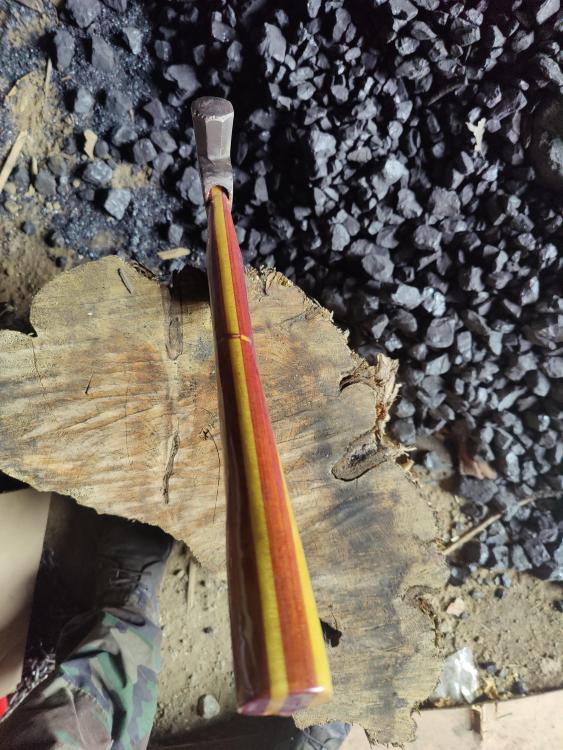

I have a hatchet handle a freind made by layering Osage and Purple heart. Quite a nice look. However he coated it in epoxy and it is slippery as all get out. -

That is one cool machine right there. Looking at though i would have guessed some kind of broach. Manual machinists are a dying breed. What they teach now in schools is almost entirely CNC. In a way it is kind of nice becuase i can walk into just about anyshop and tell them what i want to make, unfortunately the machinery i run there are 2 shops that currently have them that i know of in this area. I spent 20 years away from the industry, back then CNC guys got paid nice. When i hired into the shop i am currently at last year i got about 25% more than a CNC guy becuase i knew manual machine concepts. Over the last year and the covid 20% of machine shops in the Dayton area went out of business. You would think that many shops going under that machinsts would be a dime a dozen, how ever at 51 i am consider a young guy. Most of these older guys chose retirement or a change of career i.e. something different and easier.

-

Testing hammer accuracy

BillyBones replied to QbBlacksmith's topic in Blacksmithing, General Discussion

How many strokes? My grandfather could drive a 16 penny nail with a single swing of the hammer. One tap to set it in place then one good swing and it was set, he spent well over 50 years as a carpenter though. The reason i ask is becuase as you increase one aspect of a hammer blow you will decrease another. More accuracy usually translates into less force of the hammer, more force you will loose some in accuracy. So if it takes you say 10 strokes to drive that nail, try it in 5 and i bet you will bend a whole slew before you get it right. Once you can do it with 5, time yourself driving 10 nails, then try and cut that time in half. Again i would bet a whole bunch of bent nails before you do it. Accuracy is only one of 3 elements in a successful and productive hammer blow. -

Pretty cool article. Thomas, I am jealous. The only time i get my name in the paper, it is followed by what i was charged with. If the girl in the one photo had purple and blue hair and not green i would have sworn it was my youngest daughter.

-

I got that Dewalt porta-band not long ago and love it. It is the deep cut and would take down those springs and such in no time.

-

My vice has no markings on it. Quick question though, what are the ski slopes for? I have been doing this long enough that i can look at the most random object and usually say that would work for____. So figuring out a way to use them is no problem, i was just wondering if they have a specific purpose?

-

What did you do in the shop today?

BillyBones replied to Mark Ling's topic in Blacksmithing, General Discussion

CGL, nice to hear from you. Hope all is well and the goats are doing good. -

What did you do in the shop today?

BillyBones replied to Mark Ling's topic in Blacksmithing, General Discussion

Sindoc, all us pro's know you leave at least one shot for the AM. Coupled with a raw egg and you will feel new again. Spent the day yesterday playing in the dirt. Dug 8 footers, 14" wide 36" deep, and mixed 50 bags of concrete. 16, 1/2" holes through 14" of concrete for the ledger. Man oh man is my back feeling it today. All this for a deck. Then when i went to get my building permit the inspector says that if i went 2' shorter i would not have needed a permit. On the bright side i did dig up some really good sized pieces of flint. -

Will this work as a decent Anvil?

BillyBones replied to Dave Toth's topic in Anvils, Swage Blocks, and Mandrels

The markings look like a lot number for the steel. When we get steel in the shop the "HT" stands for high tensile. However i must state that as with the color codes that can change from one manufacture to another as to what the numbers and letters can stand for. There is no universal standard. -

What did you do in the shop today?

BillyBones replied to Mark Ling's topic in Blacksmithing, General Discussion

Finally got out to the shop Sunday. 95* with about 95% humidity. I worked for a while, rested a bit worked some more but at the end i had to push to get done and the work reflects that. Then went and figured it was time to quit, grabbed me a cold adult beverage, sat under the tree in the shade and promptly passed out from dehydration and heat exhaustion. (didnt even get to enjoy my beverage) Take my experience as a lesson, quit when you are getting fatigued, do not push it. The work gets bad and you end up laid out in the back yard. And drink plenty of water and maybe some gatorade or pedialyte to get those electrolytes and such back. Anyway i did get some marshmallow/hotdog sticks made for the grandkids. The forks were folded, welded, and then cut to separate. Tapered and flattened. You can see how uneven and crooked the forked ends are from getting fatigued. 1/4" round bar i just grabbed at the local hardware store. -

Forge welding, how to see when it's ready?

BillyBones replied to DennisCA's topic in Blacksmithing, General Discussion

Sorry, i miss read that. I did not realize you are getting it from a blacksmith's shop. Like Frosty said they will get you what you need and pointers on how to use it. -

What did you do in the shop today?

BillyBones replied to Mark Ling's topic in Blacksmithing, General Discussion

The reason i decided i did not want to be a blade smith. -

What did you do in the shop today?

BillyBones replied to Mark Ling's topic in Blacksmithing, General Discussion

A couple years ago a guy brought a Yugo into the shop. Of course my first response was this thing is still driving !?! Then You really want to fix it !?! Well it needed rear wheel bearings. The ones on the passenger side were held to the axle with a left handed nut. I found this out the hard way of course by hitting it with a thousand pounds of breakaway torque. Ok, call the parts store and get a new hub, no big deal right? Except that it was an '84 Yugo and the parts guys were all You got a what? They really want to fix it? Took a while but we finally got it fixed. -

Forge welding, how to see when it's ready?

BillyBones replied to DennisCA's topic in Blacksmithing, General Discussion

Dennis, when you get the Borax put on an old cookie sheet in the oven on low heat for a couple hours. Then store it in a sealed container. I use an ammo can. Borax contains water and when you put it on hot metal the water will boil and cause it to foam. Baking it will evaporate the water but borax will absorb water from the atmosphere hence the need to keep it sealed. Not as good as anhydrous borax but better than just borax. It is not that hard to make anhydrous borax but involves melting then grinding it to a powder and i am to lazy so i just put it in the oven. Edit: forgot to add, if that is the standard size i am on about year 4 of mine and still well over 3/4 of it left. -

What did you do in the shop today?

BillyBones replied to Mark Ling's topic in Blacksmithing, General Discussion

Nathan, nice truck, even though its made by that one company and not a GMC. ( just funnin ya) '67 Nova not sexy? That and the earlier deuces were one of my favorite body styles. My dad just sold our '66 Mustang. We traded a '67 Belaire for it, now to find us another project. I am pushing for a ratrod. George, many European cars still use a lug bolt rather than a nut and VW used to use left handed bolts. Like i said, did the brakes on my truck yesterday, a proper truck, a GMC. I hate those chrome capped lug nuts. Half of them had that little bit of rust under the chrome that split the cap, stuck in my socket, got beat out and are now missing the caps.