-

Posts

2,506 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by BillyBones

-

My first Hot Cut Hardy tool

BillyBones replied to Bantou's topic in Hot Cuts, Anvil devils, metal cutting on the anvil.

Your lucky, my dad between the time he got out of Vietnam and the time he re-enlisted, about 5 years or so, he had an afro, wore the polyester shirts with those big wide collars, bell bottoms and lamb chops. -

My first Hot Cut Hardy tool

BillyBones replied to Bantou's topic in Hot Cuts, Anvil devils, metal cutting on the anvil.

P-nut, i just imagined you with the rolled up cuffs, tucked in white t-shirt with a pack of cigarettes' rolled into the sleeve looking all James Dean or maybe Marlon Brando. -

My first Hot Cut Hardy tool

BillyBones replied to Bantou's topic in Hot Cuts, Anvil devils, metal cutting on the anvil.

Series of holes? Some of mine look like lace! Best thing i have found for a burn. When i first started smithing someone, and it may have been some one here, told me that as soon as you get burned, say your hand, stick it in the slack tub and keep it moving until the pain goes away. It works. Not real feasible though to stick half my leg in there, not only can i not lift it that high any more, i would have to get half naked. It would be cool to see the look on the neighbor if they saw me half naked with my leg in a barrel of water though. -

My first Hot Cut Hardy tool

BillyBones replied to Bantou's topic in Hot Cuts, Anvil devils, metal cutting on the anvil.

Scale can also set your britches on fire. I know this from the huge scar i have on my leg. It will also burn small holes in the bottom the legs, no big deal at the time except they are just at the right height to catch on the hooky things for my boot laces about a 1/2" higher than where they would be with the waist on my belt line. So it tugs down enough to be annoying and you have to give a little slack to get it undone and...oooo its frustrating. -

The pump is an internal gear pump. It has one small drive gear with a larger internal toothed ring gear running eccentric to the drive. like a Ford transmission pump. I believe what you would want is an external gear pump where it just has 2 gears squishing fluid between them. Honda transmissions do however use that style of pump.

-

Stopped by the tranny shop i used to work in to say hi and scored a few things. An out put shaft for a 4T65, a pump shaft for a CD4E, 5/16" hex, a couple brackets to hold torque convertors in during transport, pins, a hand full of engine lifting eyes, 2 big tow hooks, and a Honda power steering pump. The pump runs off of the speedometer gear in Honda transmissions, you can hook a drill up to the little shaft end and they make great fluid transfer pumps.

-

Can't forge weld - workpiece cooling too fast

BillyBones replied to CrazyOatmeal's topic in Blacksmithing, General Discussion

Put an anvil on or next to your forge. When i am trying to weld small stuff i set a block of 4140 that is about 15# on my forge. You do not have to hit it real hard to get the weld. You could even use a sledge hammer head to do it. I use a coal forge so i can just skootch some coal away for enough space. If you are using a gasser you may have to rig up some kind of table or something. Goods beat me to it. -

This is what i know about electricity: call an electrician. I have done some pretty crazy things in my life, i have been in some really dangerous situations, some i may should have not walked away from, but electricity scares the bejeebus outa me.

-

What did you do in the shop today?

BillyBones replied to Mark Ling's topic in Blacksmithing, General Discussion

Alexandr, i thought at first you had to clean the legs of the barstools in the restaurant, then i scrolled down. As always very nice work indeed. Snuffy, that is a right nice piece of work on that candle stick there also. -

Mail call ? 2.5 ton of stoker. Got the left overs from what they did not want at Carillon park's blacksmith shop. I am pretty stoked.

-

What did you do in the shop today?

BillyBones replied to Mark Ling's topic in Blacksmithing, General Discussion

IDF&C, we have a store here called "The Hardwood Store". That is all they carry is hard woods. He has a huge selection also from exotics to domestics. He will buy lumber from houses, barns, etc. being tore down like the tiger maple he had for a while. So some of it will have paint and the like. But a peice of walnut or hickory or something similar he gets from the mill. Paul, screw jack stands are also pretty commonly used by mechanics. When i was slinging transmissions i would put one under the rear diff of big trucks to steady them on a lift, or support an engine, whatever i needed it for. -

When i first started forging i was using a gasser that constited of 6 hard fire bricks in a metal frame. Not to heavy but i too had to tote it in and out of the basement along with propane tanks, hoses, etc. May not have been heavy but 4 or 5 trips up and down the stairs each time i wanted to fire it up became a real PITA. The wife didnot say anything about it, i was more worried somebody would want my tanks and tools more than i. So i had to do something. Can you put a small shed like thing in your back yard? I built one but my mom and dad bought one. A shed thing that is maybe 4' x 4' x 3'. The top is hinged and the front is 2 big doors that swing open. Fit my forge, on an old propane grill, 3 tanks 20#,

-

What did you do in the shop today?

BillyBones replied to Mark Ling's topic in Blacksmithing, General Discussion

I made a jig for doing collars. In one of Mark Asprey's videos on the lvl 4 grille he shows collaring the pieces and i copied his jig. Basically 2 pieces of angle iron that fit the vice with 2 smaller pieces welded on a bit from the edges. This provides a space to shape the collar while supporting the sides and bottom of it. He does make it, like everything else he does, look much easier than it actually is though. -

What did you do in the shop today?

BillyBones replied to Mark Ling's topic in Blacksmithing, General Discussion

Started another coffee table. Needed a better jig for my scrolls out of a little heavier material. The one i have been using i made as a one off for something else and is kind of flimsy. This one is pretty stout. 1 1/4" x 1/2". I also got the bottom supports done and the crossbars. I will start the legs this week. I am thinking maybe walnut for the top, the people i am making it for want a darker wood. But we will see what the hard wood guy has. -

JHCC, wind the wire up on an old 10# spool, cut it and put the rest away till needed again.

-

Traditional crafts you say? Well brewing and distilling are traditional crafts! We may have just figured out a bypass of those liquor laws also.

-

Swinging a striking hammer, rail road swing

BillyBones replied to Glenn's topic in Blacksmithing, General Discussion

When i was younger we used to challenge each other by taking a sledge, 8#, holding the end of the handle at an arms length with the head straight up. Then just with the wrist lower it down slowly to touch your nose and back up right. -

Carbide Burr on Stainless

BillyBones replied to edennis's topic in Blacksmithing, General Discussion

Forgot about this topic. I need to correct myself to start with. A bur to me is something all together different than what we are discussing. Hence the reference as to how chips look when drilling. So anyway, yes you can run it faster than i stated. However your speed is dependent on a couple issues 1) diameter of the bur, the bigger the bur the slower you go, 2) how much shank is exposed, more shank go slower. Ideally you want a feed rate somewhere between 1,500 and 3,000 FPM ( (RPM) x PI x (diameter) /12 to get feed rate) Using a 1/2" bur at 15,000 rpms. 15,000 x 3.14 x .5 / 12 = 1,962.5 FPM. So FPM = RPM x 3.14 x Y / 12. (Y being the diameter of the tool.) RPM = FPM x 12 / 3.14 x Y (Y being the diameter of the tool.) These are the basic formulas for figuring out speed and feed rates. What you have to figure out is what is the ideal feed rate of the tool you are using. You can get that info from a machinest reference book, the tool maker, and even the supplier of the material. -

When my grandmother passed in January a few years ago my uncle was cleaning out the house. He put the refrigerator out on the porch. Come along about September some one opened it. He had left a package of fish in the freezer.

-

"GO GO Gadget power hammer!" I does bite getting old. New Years day i tore a ligament in my knee just by standing up. I did finally go get glasses when my arms became to short to read something. Thomas, would have been epic had your friends joined also and made it 3 half naked wild men running at them with spears. You guys should have formed a neighborhood patrol.

-

Frosty, that is an excellent description of swinging a hammer. I have tried to put that into words many times but i am no wordsmith. My grandmother had the rheumatiz bad in her hands. She had the classic big knobby joints and fingers going side ways. She swore by peanut oil. She would use it as a rub on the joints.

-

I never forget to drink, oh...wait, you mean water. Actually that is another thing. Alcohol consumption is also bad, or at least i have been told. Another thing is meat consumption. I get the gout when i eat lots of jerky. I had a friend who would get it eating raw steak. (yeah i know, but he loved him a raw filet mignon) I think it is something to do with not cooking it, jerky is dried not cooked after all. I also have what my grandmother called shaky hands. My hands will just start shaking out of nowhere. If i am holding something i have to set it down. James Bond likes my martinis though.

-

Maybe try Uri Hofi's method? I can not explain it, nor do it, but it is almost like he grips the hammer with just the finger tips by the sides and not the palm which seems in line with the top of the handle and not the side. That is not quite it, but the best i can explain it. He has done a few videos on the ergonomics of holding a hammer. You can find them on the you tube and there was a couple links here but i cannot find them right now.

-

C50 in the states is equivalent to 1050. At least that is what the inter web machine tells me. So i would say, why not? I can see a few things. Tomahawk, adz, garden trowel or spade, etc.

-

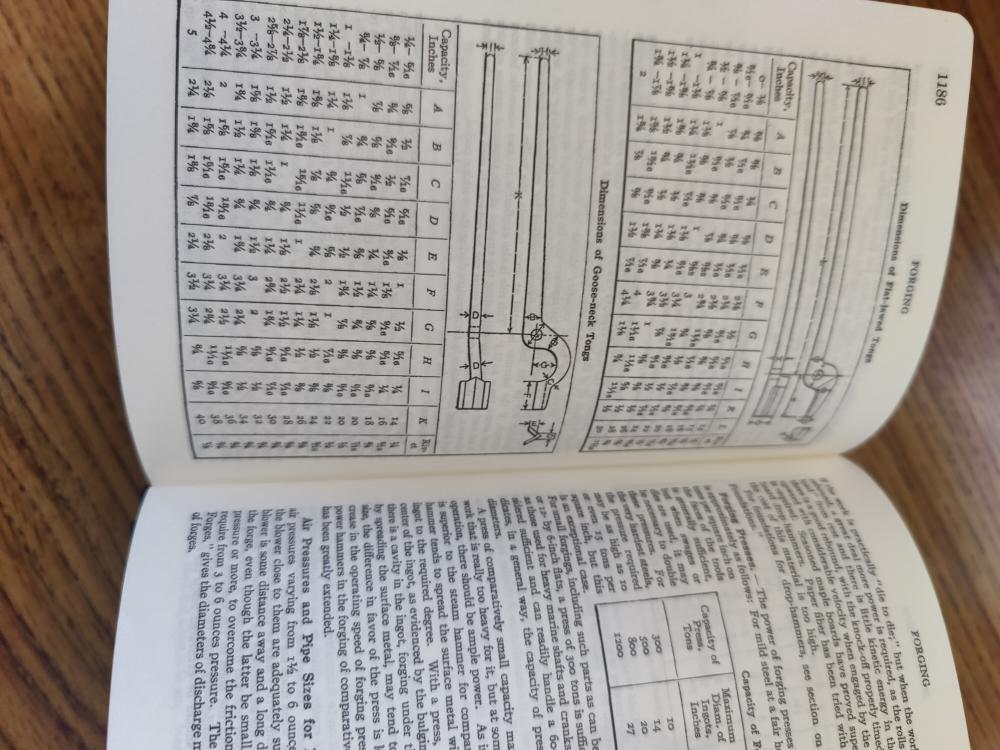

Thomas, i had also forgotton that liability issue. It is more common here now to see new trucks getting lifted and such. I always liked the look on some ones face when the warranty company would not warranty a transmission becuase they had modified the truck by lifting it and putting on huge mud tires. Anyway my door bell just rang, mail call. I said something about this in another thread so i went ahead and ordered it. It is a replica but a 1st edition 1914 "Machinery's Handbook". The section on forging covers things from tuyere size to what floor is best. Even has different forge welds. And a teaser of the forging section.