-

Posts

24 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by straycat_74

-

local police said that since I "Invited him into my home" and "contracted with him for services" that there was nothing they could do. they suggested a lawyer and sue him. Turns out (name redacted) he's a pedophile, child rapist, registered sex offender, convicted felon, and Meth addict (none of which did he admit to when I hired him on short notice) the lawyers said it'd cost me $6,000 to sue him, and as a meth-head he ain't got nothing worth taking so I'd be xxxxxxx good money after bad. tried local newspaper, but they refuse siting 'libel and slander' as unpublishable. the stress from fighting this for the last three months led me to make a stupid mistake which has now cost me my job of 7.5 years as an OTR truck driver. I'll be unemployable as a trucker for at least a year, along with loosing at least count some $12,000 worth of tools (anvil included) and personal affects including the Marlin Spike knife my grandfather carried for the duration of WWII while he was on Destroyers in the pacific. (that knife was the only thing I had to remember him by). *Sighs* so yeah. none of my friends or family will help. I've tried reaching out to the local blacksmithing and knife making communities, but I got banned from most for "Begging" broke, robed, fired, hopeless and helpless. I'm at my wits end, guys... here are pictures of my anvil, the one with me leaning over it was taken the day I got it. there'sa couple vids on my youtube of me using my anvil... I'm in tears here. they do, but the ... JERK (I promise I'm trying not to swear here) was operating without a business license, no insurance, and refused to sign a contract. See my above reply. unbonded, unlicenced, uninsured.

-

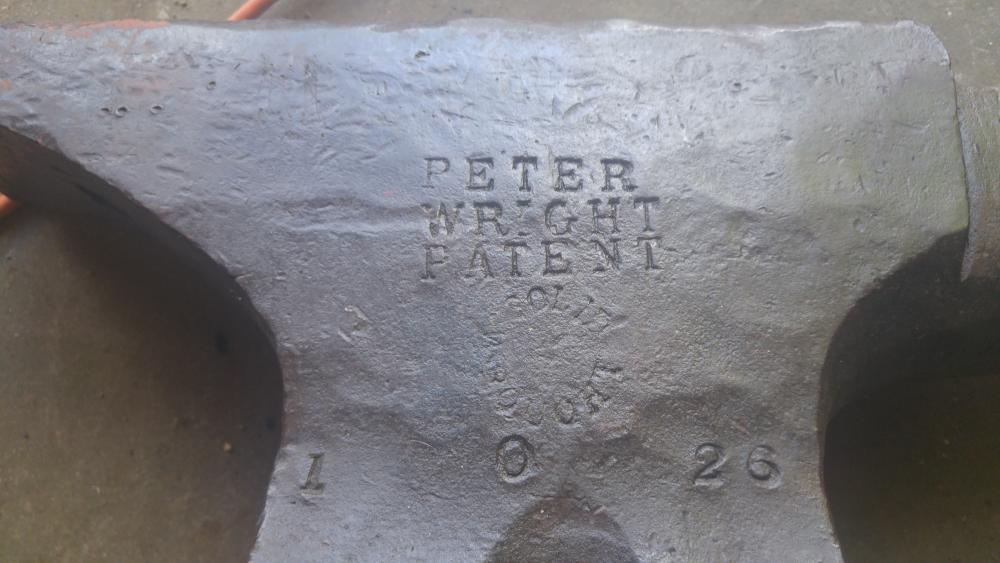

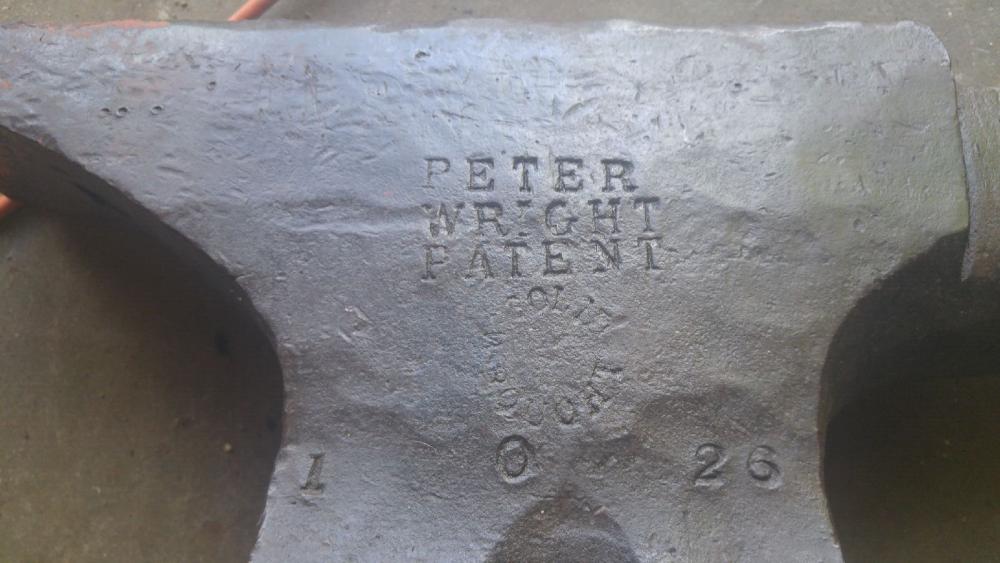

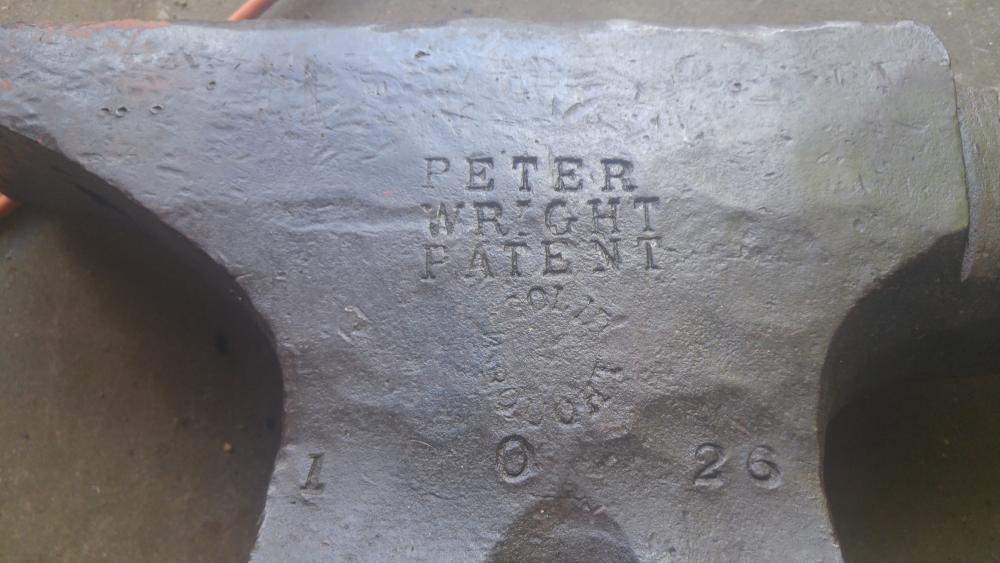

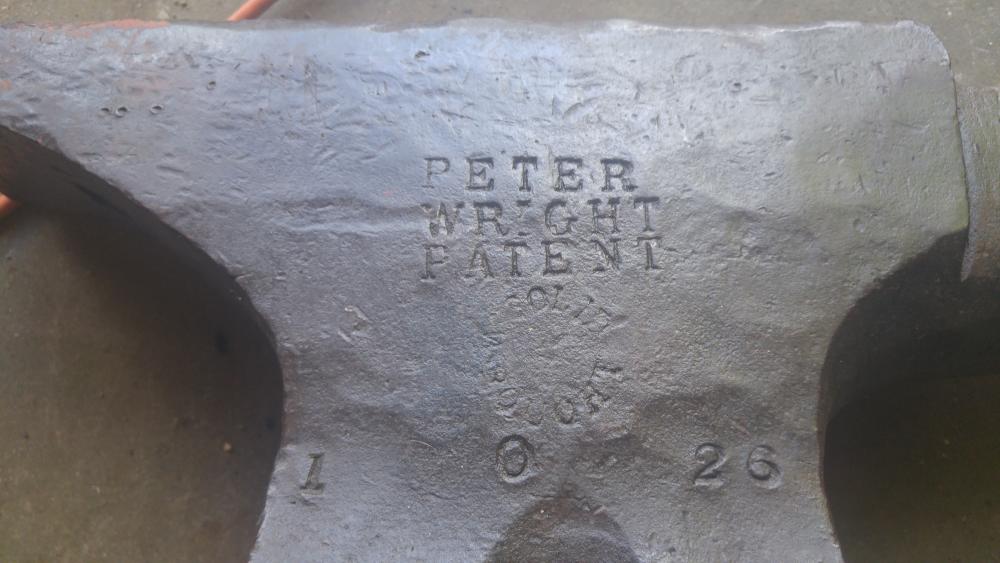

recently I moved out and had to use a local mover on short notice. this weekend he unloaded my stuff after 6 months storage so I could finally get back to my life.(long story, not relevant) and my anvil is missing. my 138lbs 120+ year old Peter Wright Anvil, is "missing". it's one of a dozen things that didn't end up back at my place after the storage period. my heart is broken, and most of my home brewing equipment is as well.but my ANVIL. I wanna hurt someone. SO I am out of the forging thing... because I'm not good enough to actually SELL anything... until I can Power Hammer, or get my anvil, or a replacement. and JUST to rub salt into the wounds, I'm an over the road truckdriver, I have to leave in the morning and will not be back for 2 weeks. the mover has repeatedly claimed he was going to return my stuff, but I think he's just delaying sincehe's now trying to place a lein against my truck and my motorcycle "until I pay him" and I found out today that he has a criminal record

-

recently I moved out and had to use a local mover on short notice. this weekend he unloaded my stuff after 6 months storage so I could finally get back to my life.(long story, not relevant) and my anvil is missing. my 138lbs 120+ year old Peter Wright Anvil, is "missing". it's one of a dozen things that didn't end up back at my place after the storage period.

my heart is broken, and most of my home brewing equipment is as well.but my ANVIL. GOD I wanna hurt someone.

SO I am out of the forging thing... because I'm not good enough to actually SELL anything... until I can Power Hammer, or get my anvil, or a replacement.

and JUST to rub salt into the wounds, I'm an over the road truckdriver, I have to leave in the morning and will not be back for 2 weeks.

-

trial etch on the cable knife. I also used it to chop a 2x4, and got a slight delamination on the blade edge that you can JUST see with the single exception, I thought this turned out pretty good it was actually supposed to be a leaf bladed dagger, but the steel wanted to be a bowie, so that's where I went with this WIN_20170529_21_46_55_Pro.mp4

-

Nothing illustrates how out of shape you are from 17 years playing steering wheel monkey (17 years as a otr truck driver) than trying to forge weld a 1 inch piece of cable on your ONE day off this week >.< got half of it forge welded, one inch at a time, three cycles each... before I ran out of steam and couldn't lift the 2.25lbs rounding hammer I only JUST got in the mail yesterday I'll try to get some pictures on my phone when I can lift my arms again... also, twisting wrench I "made" with a one foot bit of rebar (only my second time welding with a wire feed)

-

my first forge I musta run for 10-12 hours off of a 20lbs propane bottle. I finally ran out the otehr day so I took my 40lbser to Ace Hardware to get it filled. Was cheaper than bottle exchange! swapping bottles (around here anyway) is $22-25 for the 20's, but getting a 40 filled was only $29! I run two 1/2" burners with .025 mig tips around 10-12psi as as long as the stuff I'm working on isn't too thick I can even forgeweld with it

-

there are a couple of us around central WI... I'm only home every other weekend, but I made a propane forge. not the best, but I've limited funds. already starting to collect stuff for my "next bigger better badder forge" and will get it done... oh, at this rate... next winter XD personal experience: the forge isn't the hard part. ANVIL was what kicked my but trying to find/afford

-

oh goodness I haven't made chainmail in decades. being cheap and broke most of my life I used 14ga galvanized fencing wire, a 3/8ths dowel rod for winding, power drill (usualy cordless) and the lid from a 50caliber ammo can to put the other end of the dowel into. I've tried using a Dremel, I've used wire cutters of various sized and configurations. I think the wire cutters I used most looked like a very small set of bolt cutters... and I wore out like 5 of those cheap things. I got pretty got with 4-in-1 weave, but never had the time to try others.

-

I tried a RR-track anvil and was NOT happy with the results. my first "real" anvil cost double the "going rate per lbs" but was, I believe, well worth the money. first it's at least older than 1880 based on the markings, second it's in decent enough condition for a VERY used anvil and lastly, I've ALWAYS wanted a 'REAL' Anvil. granted, I could have bought a new one thru HD for $800+, but I didn't HAVE the extra $300 to spend at the time. could a GOOD smith do Good work on a RR-track? probably, but I'm not there yet, not even remotely close... better tools, less garbage to blame for when you mess up, cause a tool THAT expensive obviously CANNOT be the problem :3

-

howdy folks, Straycat_74 here in Wisconsin Rapids, Wood County, central Wisconsin. looking for other smiths in the area to hang out, do some forging, and chat/networking. I'm still rather new, and I work as a truck driver too much to make Much headway in teaching myself much, so having another local smith to chat with would be awesome.

-

What oil should I use for quenching?

straycat_74 replied to Forging Carver's topic in Heat Treating, general discussion

as a former diesel mechanic I kinda figured this would be the answer, but it's best to ask. -

POP: King Of Random on youtube. the metal I'm using for the forge is literally two Ravioli cans, and no. it won't last at these temps, but this was a "figure it out as I go along" kind of situation. my next forge will be Perlite/sodium Silicate and a used (rusted thru) propane tank. actaully I wanted to ask your opinion on perlite and sodium silicate as refactory... Tongs, I have a few but they are "some assembly required" and have to be finished... I don;t know how you feel about advertizing, but I got 5 sets of tongs what I found two professionally made tongs for... anvil height: yeah, I have some 4x6 laying around I am going to make a platform to raise it up 4 inches. I also need to secure the anvil to the stump yet. I work 70+ hours a week on the road, so I only get 60-72 hours off every other weekend... cooling off too much: when I was standing over it I couldn't hear a difference, maybe because I didn't Know you Could hear a difference? (newbie) and yeah, which is one of the reasons I'm using cheap xxxx disposable RR spikes so I can learn to move the metal the way I see in my head (also why I haven't made those tongs yet) before doing anyhing with Expensive metals. youtubes: I've added Mark Aspery and Brian Brazeal to my "watch sooner rather than later" list shorts: it was 95 degrees that day, and I sweat at anything over 70. an apron is in order, once this months bills are paid. now that it's fall, I'll be breaking out long pants and socks sooner. oh, and as for the damage the falling bit of steel caused, there was a deep scratch, but no burns. hurt because that was a fairly heavy bit hitting a tender bit, but no burns (fortunately it wasn't on skin more than 1/10th of a second) I live in the Wisconsin Rapids area (will add that to my profile in a bit) and I KNOW there is at least One Blacksmith int he area (the fastenal guy said so) but I am home so infrquently I don;t really know anyone in town, despite living there for over 10 years now... so I am open to the possibility of groups btw, thank you for taking the time to see how badly I'm xxxxxxx xxxx up (even if I'm not really doing all THAT bad) and offering constructive criticisms here's what the RR spike looked like after I cleaned it up on the grinder/beltsander. I know RR spikes don't heat treat well at all, but I think I wanna harden it when next I get home.

-

my first knife. 01 steel, 1 1/4 inches wide, 1/4 thick. this was the last 6 inches off an 18inch bar-stock (the other 12 inches is still a work in progress) blade is 3.5inches long I got in such a hurry to put a handle on it, I forgot to heat treat it. handle is oak, pinned with brass, then epoxied into place. I hit the handle with a bit of stain because the stain was open.

-

What oil should I use for quenching?

straycat_74 replied to Forging Carver's topic in Heat Treating, general discussion

May I ask WHY not to use used motor oil? my guess would be impurities and the fact that the reason motor oil turns black is it's burnt already I think I missed the post that covered this already. a link to that post would be most welcome. it is in the heat treat sticky's -

grabs my coffee beans and hides them from you heathens... using some freeze dried swill for etching is fine, but stay away from my fresh ground $50 a lbs coffee or there'll be fighting words spoken... I take my coffee VERY seriously.

-

so basically, store bought borax needs to be baked and or mixed before using? good thing I haven't gotten to forge welding yet >.<

-

I was wondering about where to get some of that... thanks for the info!

-

-

I have a couple of youtube vids of my attempts at teaching myself blacksmithing I say "teaching myself" because I live in the middle of nowhere and I only get ever other weekend off (truck driver) my forge is two ravioli #10cans tack-welded mouth to mouth, 4.5inch hole cut into it so I could pass a 4" PVC tube down the middle (casting the opening) and then sand and plaster of paris as the refactory. my burners are from a vid that Turner forge did on youtube, but is fairly close to Frosty's T-burner. (mine are only 1/2inch instead of 3/4, with a .025 mig tip and 0-20lbs adjustable regulator) here's a couple of links to my vid's, feel free to let me know what I'm doing wrong

-

oh now that's a beaut you got there. how much she weigh?

-

just goes to show that even masters of the forge like Frosty can typo once in a while thanks for letting us know you are actually human there Frosty

-

forging a leaf key fob presentation

straycat_74 replied to Mark Ling's topic in Blacksmithing, General Discussion

oh, nicely done. I wish I had your skill -

I recently picked up a 138lbs Peter Wright off of craigslist. I could only talk him down to $500, but I don't feel To cheated as it IS a fairly nice looking PW the edges could be better, and she doesn't have that great of a ring, but I like her. I couldn't find a tree stump I liked, so I made one out of 4"x6"x8' cut to 22inches, glued and bolted together I ended up having 8inches of 4x6 left over, cut corner to corner to add stabilizing feet to the stump... just in case