-

Posts

1,300 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by primtechsmith

-

Hefaiston 2008 photos available now

primtechsmith replied to Jan's topic in Blacksmithing, General Discussion

Very beautiful work. I really like the style of several of the pieces there. Inspires me on a new fireplace set idea... Thanks for sharing the link! Peyton -

I was the guy set up selling those things... And yesteryearforge is the guy who makes them. They are available on ebay. And they have run here on the auction page. Buying it here helps the site! We now have in stock our Version II which has over 100 size variations with it. But I will not go into a sales plug here...you can go look on ebay or the auction page and read the description. S Hooks: At Yesteryear Forge we have prescribed sizes that we make our hooks from. Generally it is 1/4" round, but we also do them in other material. The length material I have set for production is 6", 8", 10", 12", and 14". These are the sizes we make a lot in...we do and can go bigger in length and material per special orders. I have two main ends on my hooks. One is a curly Q, or pig tail...how ever you call it where you are in the world. And the other is a flat end...sort of like a mini fish tail. One end takes 4 heats(curly Q) and the other takes 2(mini fishtail). I set up and do runs of 6-8 in the fire at once to increase my speed. I can on average turn out 30-35 hooks an hour and they sell for about 3.00 USD a piece. I will try and see if Mike has any photos at home of the hooks and stuff to post. I am in my classroom right now with my kids taking a test so I am limited... I hope this helps. Peyton

-

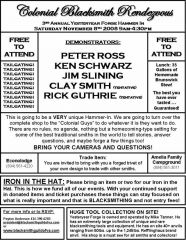

Jessie will be demonstrating the techniques of using a striker. So someone, or a few people will be swinging some big hammers on Saturday! Peyton

-

Welcome to the greatest state in the country! We have a guy who sells 50# bags of coal at our meetings. It is pretty good stuff. A lot of our members buy from him, and the blacksmithing school where we meet uses it as well. Here is a link for info on our next meeting: Blacksmith Guild of Viriginia - Home PLEASE let me know if I can be ofany help to you on getting settled here in Virginia. Peyton Anderson President, Blacksmith Guild of Virginia

-

This or that (New anvil purchase)

primtechsmith replied to rustyshackleford's topic in Anvils, Swage Blocks, and Mandrels

Also, Blacksmith Supply is about an hour from where our meetings are here in Virginia. You could purchase one from John and come up here for a meeting pick up the anvil from him. It would save you on shipping, and let you hang out with some of the smiths up here too. Also Alwin Wagener and Elmer Roush use Euroanvils...along with the instructor's anvil at the Yesteryear School of Blacksmithing is a 500# Euro. ...just a suggestion Peyton -

Quad-State 2008....Shout out if your going!!

primtechsmith replied to keykeeper's topic in Events, Hammer ins, Where to meet

Looks like the weather is going to be perfect for a great time! mid to upper 70s and NO RAIN! Ye Haw! I will be heading out with Mike, Linda, and Sarah Wednesday afteroon after Sarah and I kick all oyr kids out of the classroom. Will be there setting up Thursday, and ready to go for the weekend. I am excited!!!!! Peyton -

I know the seller personally and his integrity is NOT in question. John is a very fair and reputable dealer. Those hammers are bought from an over seas distributor. They are extremely soft. I have one and was not happy with it. I think we all need to keep in mind that sometimes the price of something will automatically tell us the quality of it. This hammer is great for a beginner, or someone who is not quite sure if this style is for them BEFORE they spend the big bucks on a Hofi or Tom Clark. These types of hammers are sold by just about every blacksmith tool dealer out there. So it is not just him... Peyton

-

SATURDAY October 18th 2008 10am-4:30pm ~NEXT MEETING~ Where: !!!NEW!!! Yesteryear School of Blacksmithing . Crewe Virginia . 1918 West Virginia Ave (US 460) 23930 Lunch: Brown Bag it, or local eatery Demonstrator: JESSIE WARD Info: Jessie is an active instructor at the Jacksonville Folk School in Floyd Virginia. Her knowledge of not only blacksmith but shoeing horses lends itself to a very unique and extremely entertaining demo! Reminders: IRON IN THE HAT! and bring a chair! SPECIAL LADIES EVENT! ALL LADIES GET 5 FREE IRON IN THE HAT TICKETS! Directions: The School is located on US 460 in Crewe Virginia. Google Maps I hope you can attend this very special event! Peyton

-

Leaf hook issues

primtechsmith replied to easilyconfused's topic in Blacksmithing, General Discussion

I have had the same issues in my explorations of my leaf making. I have had a couple of suggestions that have worked out quite well for me. 1. Work the piece hot, and stop early. When it goes cold it becomes more brittle and the vibrations will take its toll. It is kind of like bending a paper clip back and forth...small cracks begin to appear and then it finally breaks off. When hammering out the stems the end of the leaf is out there bouncing and vibrating around... 2. Leave the stem thicker at the leaf and thing that out last. This sometimes keeps the stress down. 3. The best thing for me so far has come from an instructor who lives around here. He told me to quench up to the point where I am working. It will harden it enough until you are done. That has been a saving grace for me... 3. Watch for cold shuts. I have to be really careful when I make them on the edge of the anvil because admitedly my hammer control is not as great as I would want it to be. A misplaced blow in creating the shoulder for the leaf can result in a lot of frustrations. I use a c frame guilltone tool to do all my leaves now. I hope this helps. In no way do I admit to know what I am talking about, these are just some things I have been told when making leaves and have helped. Which if you ask Mike I make and put on everything. Truth hurts!! HA! Peyton -

Quad-State 2008....Shout out if your going!!

primtechsmith replied to keykeeper's topic in Events, Hammer ins, Where to meet

I am going to be set up with a forge going all weekend demoing and selling Mike's tooling(c frame guillotine, and s hook jigs). Please come on by and say hello! We will also have some other newly fabricated goodies that you won't be able to turn down too! But those will be a surprise! I will be beside John Elliott of Blacksmith Supply. Peyton -

On Saturday I had the chance to get out at the forge and light it up. I hadn't since mid-June. Things have been busy and there just wasn't a chance to get out there until yesterday. I spent a good majority of the day hanging out with my mentor and getting some things made up and ready for Quad State. It was good to get some "time on the couch"...who needs a shrink when you can get out and release some pinned up energy at the forge with good people! Besides I would rather talk to my fire than a Dr. any day! HA! :)Peyton:)

-

Time:10:00 a.m. – 4:30 p.m. Location: Yesteryear School of Blacksmithing 1918 West Virginia Avenue Crewe, Virginia 23930 Demonstrator: Peter Happny Our Next Meeting: September 20, 2008 Lunch: Brown bag it, or enjoy a local eatery! Peter offers an information packed lecture complete with tall tales and bad jokes. His demo includes a smorgasbord of techniques from practical to highly decorative ironwork. He is a self taught smith who has made his living at it for over 35 years. Possible subjects include; reproduction techniques, sculpture, hardware, practical blacksmithing and large architectural commissions. "Tricks of the trade" include using simple techniques to make your work lightweight and economical to produce. Peter discusses working with designers, budgeting, pricing and dealing with squeaky customers. (from the ABANA Demonstrator List page) DON'T FORGET TO BRING SOMETHING FOR IRON IN THE HAT! Also for directions click here: Google Maps Please let me know if you are planning to attend. Peyton Anderson president@blacksmithguildofva.com OR just post it here...

-

Quad-State 2008....Shout out if your going!!

primtechsmith replied to keykeeper's topic in Events, Hammer ins, Where to meet

Thomas. Handles are a dollar a piece. I will have as many as I can squeeze into the trailer along with everything else! Peyton -

Quad-State 2008....Shout out if your going!!

primtechsmith replied to keykeeper's topic in Events, Hammer ins, Where to meet

I will be there set up working for Yesteryear Forge selling and demonstrating his custom tooling...The hook jig, and c frame guillotine that runs over in the auctions part of IFI and also on ebay. I will also have a good assortment of hammer handles available. So bring your hammer needing handles and find one that fits. There will also be some other stuff around too for sale. At least just stop by and say hello. It is always good to see and meet all my internet friends. Peyton -

Kegs: I have recently been on a hunt here in Virginia for about 10 of these things to turn into slack tubs. Here is what I have found out about kegs in Virginia. The stores turn them back into the distributor who then turns it back into the bottler/brewer. They then decide whether the keg is suitable for another trip or a trip to be salvaged. Now the question I had was what about the salvage ones????Well here in Virginia the ABC laws state all kegs must be serialized and tracked at all times. SO when one disappears there must be a reason, and selling it to me was not one. I think they were scared I was going to make and sell illegal beer or something. So that idea is circling the drain and we are going to plan B... Peyton

-

Starting with our August meeting we will have a new "home" for our regular guild meetings. Mike will still have us back to the forge for the special Colonial Event and Brunswick Stew in November. so.... Yesteryear School of Blacksmithing 1918 West Virginia Ave. Crewe Virginia 23930 Demonstrator: Mark and Mindy Gardner Topic: Making and using the treadle hammer and assorted tools to make projects. AUGUST 23RD 10am-4:30pm PLEASE BRING SOMETHING FOR IRON IN THE HAT! BRING A CHAIR! DRINKS AND SNACKS WILL BE AVAILABLE FOR PURCHASE FROM THE SCHOOL!! LUNCH WILL BE BROWN BAG OR LOCAL EATERIES! I will have a detailed list AND map for you on where the places are. Please RSVP to me ASAP! Peyton

-

Well... The day was extremely HOT!!! But we are blacksmiths and thankfully Mike put in a few new windows, hung some box fans and went and got his big 4ft fan from his other shop! We were all a big fan of that!!!! HA! HA! Doug Merkel did a wonderful demonstration on several items. I am not afraid to say this guy is my most favorite smith I have seen and learned from. He truly is a great in my books! We had three members from the ABANA Board there: Linda Tanner, Wayne Coe, and myself. The new Central Office Administrator was also there to hang out. A big thanks to those who donated. The BIG news is the Iron in the Hat proceeds went to ABANA as seed money for the upcoming 2010 Conference. With the help of the 50+ people there and their donations of items and opening their pockets to show their support we were able to raise: Drum roll please............... $1,020.00 dollars! I hope we can get more affiliates involved in this and really help put ABANA back on track and help get the next conference off the ground! Thanks to everyone who came out. I got to meet a lot of our new guild members and a lot of new members here on IFI. It always great to put faces with names. THANKS AGAIN TO ALL THAT PARTICIPATED! Peyton

-

ABANA Vision- Live webcam

primtechsmith replied to yesteryearforge's topic in Blacksmith Guild of Virginia

Hey guys...in the excitement yesterday I did not change out of Mike's name...sorry. Peyton -

Justin Good job. I second Glenn on this one too. ALways keep your first! SOmething I have been guilty of not doing. I am looking forward to seeing what you put in the trade. I need to get busy on my piece! Peyton

-

I can also put you in contact with a few individuals who make and sell these things... Peyton

-

Mark. AT the next guild event (BGV on the 19th) there should be a couple of the tailgaters selling books. One of them is Blacksmith Supply He lives near by and is a member and good friend. He usually has an assortment of books and tapes/DVDs. Oh and welcome to the guild too! Peyton

-

I would say it is about average. and Arm & Hammer is a good brand name, and 124# is a good size. Depending on the condition of the face I would have bought it...or at least talked someone else into doing it! Peyton

-

ABANA Event 7-19-2008

primtechsmith replied to primtechsmith's topic in Blacksmith Guild of Virginia

This is not Sponosred by ABANA. It is in Appreciation for their efforts!