-

Posts

469 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by jason0012

-

old style 250 pound little giant

jason0012 replied to jason0012's topic in Power Hammers, Treadle Hammers, Olivers

the brake is laying under my welding table, i have about 50 pounds of nickle rod, and amazingly, there is still green paint under the oil and grease -

Is 12-12-8 feet a good size for a forge building?

jason0012 replied to Jon Paul's topic in Building, Designing a Shop

It sounds awful small. That said, The House brothers built many amazing rifles in a chicken coup, and Billy Merrit's shop was probably smaller than that- so I guess you just have to use what you got. -

Power hammer

jason0012 replied to Dillion Brian Grant's topic in Power Hammers, Treadle Hammers, Olivers

It doesnt take much equipment, just some know how. With timbers, levers and rollers just about anything can be moved. The longer you are involved in this trade, the more likely you will need to move big stuff, and it keeps getting bigger. -

Power hammer

jason0012 replied to Dillion Brian Grant's topic in Power Hammers, Treadle Hammers, Olivers

There is a wonderful book on the subject called " How to move heavey things". It used to be published by Lindsy. I am sure you can find a copy cheap on line. It is a basic intro to rigging. The number one rule is go slow, and number two is never get any part of you under or in the path of a load. You might want to hire a rollback truck and let a pro do it. Since you are asking I doubt you are dealing with weight that will be requiring anything like a crane or crew of riggers. I don't know the cost of the tow but should be under $500. -

old style 250 pound little giant

jason0012 replied to jason0012's topic in Power Hammers, Treadle Hammers, Olivers

The guides seem complicated, composed of several movable components. Basicly it is a double V guide though like a steamer would have used. It looks like a pretty solid design, but with lots of opportunity for collisions. -

old style 250 pound little giant

jason0012 replied to jason0012's topic in Power Hammers, Treadle Hammers, Olivers

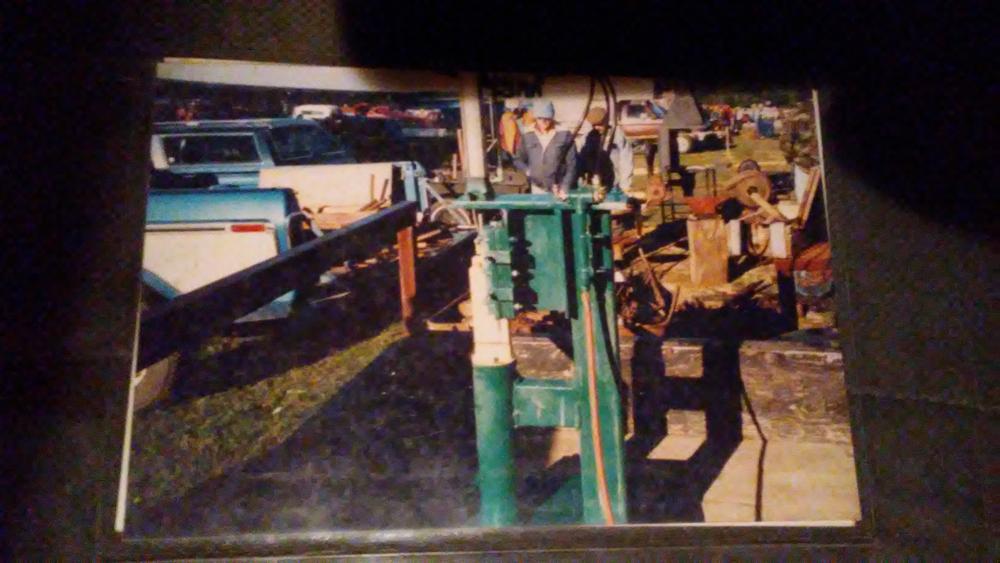

I went to visit the beast today. I am clearing a spot at the shop for the old girl and caught a few photos. I thought I took more? Oh well, it will be home soon enough... It does have a crack in the frame, with a repair. That doesn't look bad. It looks like the dies are a tad short, but obviously have been used quite a lot. The whole thing is caked in grease, which bodes well for the bearings. -

Rubber for hammer springs

jason0012 replied to jason0012's topic in Power Hammers, Treadle Hammers, Olivers

Urethane. They are apparently the same material as " super balls" were made from. A guy in Michigan made them for me in the 90s. They work well, I was just curious as I may track down another Bradley some day. -

Rubber for hammer springs

jason0012 replied to jason0012's topic in Power Hammers, Treadle Hammers, Olivers

The new ones I have are noticeably harder as well. It has been quite a long time since I had them made so I don't recall the specifics. It looks like 50-60 is the standard in industry, but all my references are somewhat lacking in details. Machineries Handbook has even failed me. -

I was just looking for any technical info on rubber for casting springs for a Bradley type hammer , and I have to admit , I am more baffled than before. It almost looks like industry gave up on elastomer springs. I was curious if anyone knows the original durometer of Bradley cushions? If I had a gage I would run out to the shop and check. Perhaps a tire shop could gage them for me???

-

I once watched Clifton forge a thread on a hammer arm. I think he did it on a dare, but it worked.

-

Well, it's done now. The fabricated fire pot works really well. Oddly, this is the first time in 20 yrs or so that I have used a modern commercial style firepot.

-

I used to have one. used it for punching 1/4" holes in thin aluminum. asside from that, I never found any application that it had sufficent power for. i sold it cheap at SOFA about 15 yrs ago. I had it in my shop about ten years and still wonder what they are good for????

-

I have this old forge that is not complete. I have done some research but have come up blank on the missing parts. All I really have is the pan and pedestal. I have built a Bob Patrick firepot but wanted to inquire one last time if anyone can explain what is missing in enough detail to replicate them. I am also torn between trying to recreate the down draft system with a good blower or use a more conventional chimney and side draft hood

-

Industrial Ajax Spring hammer HP?

jason0012 replied to Krush's topic in Power Hammers, Treadle Hammers, Olivers

P20 should make fair hammer dies. It heat treats like a spring steel. As long as they aren't too hard they should be great. P20 is used in injection molds were a really high polish is needed, the phosphorus makes for a tighter grain and better finish. I have never seen it in hammer die sized chunks, but if I had some I would give it a try. -

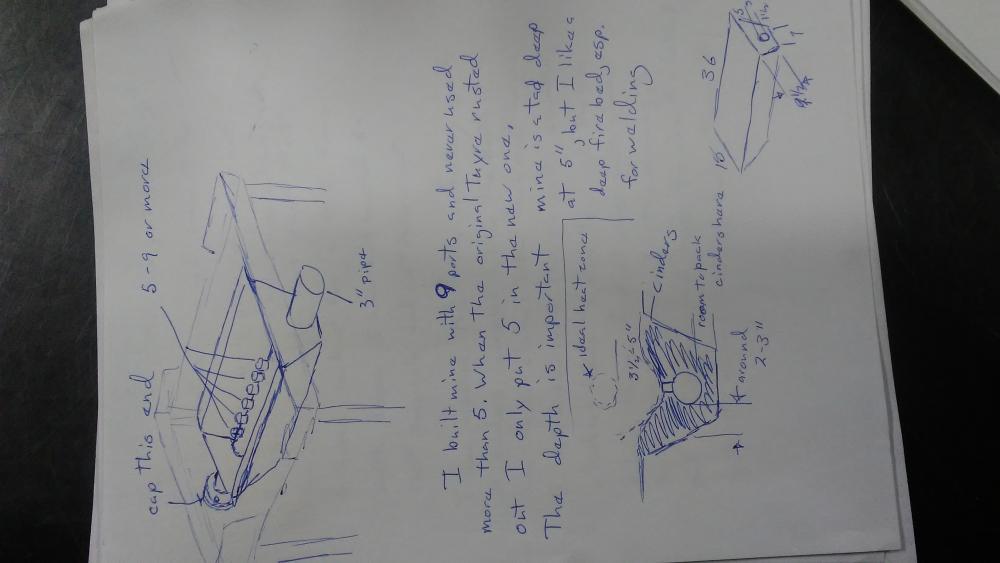

Clinker is not much of an issue as it pools below the air vents and actually seems to reflect a lot of heat back into the fire increasing its intensity. With a side draft it isn't much of a problem either. Clinker interferes with a fire by obstructing air flow and choking it. Wit this forge as with a side blast that is not likely. Now my air pipes at pretty well burned/rusted away, this is an old forge. About 18-19 years ago I made a lot of damascus in this forge and ran welding heats for 6 to 10 hrs a day without cleaning it out. The next morning I would pull a football sized Clinker out, it always had air holes in it. This is the only time I have used the cat litter and it seems to do ok. I hadn't burned coal in a few years and was a bit short on cinders when I set it up this lest time. I am on my phone and typing is kind of a pain. Here is a rough description of the plans- about as detailed as the originals.

-

Here is my forge empty so you can see how it is constructed. I think the above suggestion of a side blast forge might be a good way to go. they are easy to build and use and very adaptable. I built this before I had ever encountered one, as you can see it has seen some use. the other two are the forge in the process of packing the bed. Here I am using a mix of old cinders and cat litter, with some fire bricks to fill in big spaces. I think the plans were in the fall/winter '89 Anvil's Ring.

-

I have used a forge built from plans in The Anvils Ring circa 1990 or so by Mitch Fitzgibon for around 24-26 years. It is a variable firepot that can give me up to a 40" fire or as narrow as 6". It is very rare that a really huge firepot is useful, but when you do need that oddball heat it is nice to be able to do it, I will try to find the plans.

-

I haven't heard from him in over 10 yrs. Anybody know what Maurice Ellis is up to these days? If you want to build one there are plans on Larry Zoellers' website for a similar hammer. This would be about half scale from Larry's hammer.

-

I found a few photos,sorry they aren't the best. This was Quad-state around 94 I think. The frame was 2x4 tube I believe and the ram was 1 or 1.5x3 or 4 inch. His hammers were pretty simple but worked well. The air system was just a scaled down Kinyon.

-

Maurice Ellis built several small air hammers.The one I got to use was I think a 9 pound and ran on a little pancake compressor. It was probably 300 pounds total or less-one person could reasonably move it around. It wasn't a huge powerhouse but it would eat up 1/2inch square stock

-

Chinese Hammers

jason0012 replied to brianstucker's topic in Power Hammers, Treadle Hammers, Olivers

There was a 250 pound LG on e bay about a year ago listed for $65,000! I don't think it sold. I just paid 7,000 for one that was about on my doorstep. That seems a tad high for a little giant but well within reason. The Chinese hammers just hit a price point that is way too attractive, and I am shocked that the mechanical hammers haven't fallen in price as a result -

What constitutes a "bad" client

jason0012 replied to rockstar.esq's topic in The Business Side of Blacksmithing

I have had a few who seem to go through a lot of hand wringing over price. After redesigning a project completely 5 or more times for one client, to try to hit some ill defined price point on a 3 million plus house he still refused to give me a budget to work around. Had to just walk away from that one. -

Pneumatic or mechanical?

jason0012 replied to ThorsHammer82's topic in Power Hammers, Treadle Hammers, Olivers

I love mechanical hammers. I have used about all of them in a wide variety of sizes. Bradley, Beaudry and Fairbanks are some of the best. Little Giants and their variations- Moloch, Murray, Meyer, ect are easy to repair and have good control, but arent as heavily built as the others. Air hammers and steam hammers are a big step up. Steam hammers are the absolute best in terms of power and control, but they are also the most expensive to set up and run. Steamers are power hogs, and while they can be run more ecomonicly on compressed air than steam, the CFM required is truly alarming. Air hammers are a compromise. I have not gotten to use the Anyangs but they look like a good deal given that they are still in production and retail is about one tenth what Chambersburg was quoting at the time of their bankruptcy. As for old machines, in the US the two important ones are Chambersburg and Nazel. Both are absolutely the best hammers you could hope for, provided they arent totaly worn out. Air hammers tend to be way more expensive, but more versatile than mechanicals. My preferance is for Nazel hammers, not for any good reason, but I like the 19th century styling. Size is a big consideration too. A hammer of 25-50 pounds is a good hobby tool, a proffesional shop needs more and should be looking for a hammer in a 100 pound plus size. There is an upper limit too, and hammers over 300-400 pounds tend to exceed the operating cost limit on a small shop. I would recomend avoiding the home brew "utility type" hammers such as the Kinyon. While they do work ok they tend to be a bit slow and under powered, though a huge compressor (15-25 hp) can help. -

I contacted Grizzly and they sent me a new wheel. Problem solved, but I still would like to know why it took a crap on me suddenly like it did.