-

Posts

2,478 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by njanvilman

-

Next time you need answers like this, start a new thread. Questions like yours get lost when added to the end of an old thread. And it is bad manners to add onto an existing thread about an unrelated topic.

-

A couple questions about my anvil

njanvilman replied to andrerich517's topic in Anvils, Swage Blocks, and Mandrels

Nothing needed except a good wire brushing, then use it. Do not grind or sand it. Just use it. -

100 is the weight in lb. 219578 is the serial number, indicating it was made approx 1945- 1947.

-

According to AIA, the anvil was made around 1910 - 1912.

- 10 replies

-

- arm & hammer

- age?

-

(and 2 more)

Tagged with:

-

Show me your portable holes

njanvilman replied to Glenn's topic in Anvils, Swage Blocks, and Mandrels

I have seen that up in the Michigan Wilds, and it is a piece of Functional Industrial Sculpture, that has a million and one uses. -

Weight of Fisher sawers anvil

njanvilman replied to humphreymachine's topic in Anvils, Swage Blocks, and Mandrels

I will check out my anvils tomorrow and see what the range was with handles. -

Weight of Fisher sawers anvil

njanvilman replied to humphreymachine's topic in Anvils, Swage Blocks, and Mandrels

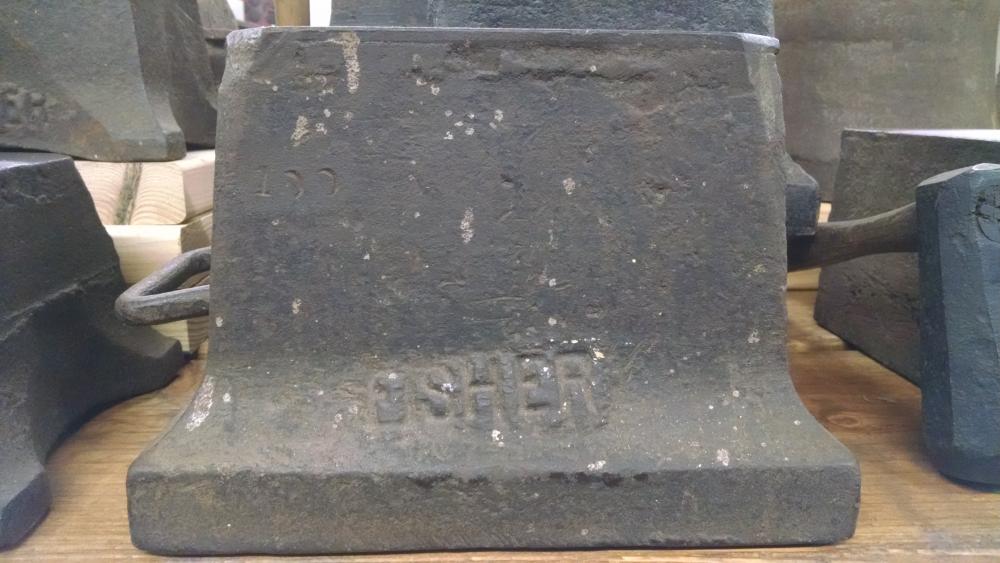

I have several original wooden patterns displayed with actual anvils made from them. That is the wood pattern that made the one next to it. The largest saw anvil listed in the Fisher catalog is 700 lb. I have never seen any larger than ~500 lb. I doubt they made too many of them. I added one photo of how the weight was stamped in on these anvils. This is a 100 lb Fisher sawmaker's anvil. I did recheck some and only about half have the weight markings. Fisher stocked anvils in the common 50 lb increments, but they offered almost 75 standard sizes. If they did not have what you wanted in stock, they could make it with a two week window. They kept hundreds of patterns ready to go. -

Weight of Fisher sawers anvil

njanvilman replied to humphreymachine's topic in Anvils, Swage Blocks, and Mandrels

Fisher Saw Anvils had many different designs, depending on the era and size. See the attached photo for some of the varieties. The ones shown here are between 50 and 191 lb. -

Weight of Fisher sawers anvil

njanvilman replied to humphreymachine's topic in Anvils, Swage Blocks, and Mandrels

Fisher listed at least 75 different stock Sawmaker's anvils in their catalog. Some were identical weights, with different dimensions of the face and height. Some of the weight increments were as little as 5 lb, on the bigger ones they had 50 lb jumps. All of the Fisher sawmaker's anvils that I have that are marked with a weight, it was stamped in manually after the anvil was made. Check your anvil carefully for the stampings. I might have it. But I also have some that were never stamped too. -

Weight of Fisher sawers anvil

njanvilman replied to humphreymachine's topic in Anvils, Swage Blocks, and Mandrels

Fisher lists this size anvil at approx 375 lb. They always did a final weighing and stamped in the actual weight. -

Weight of Fisher sawers anvil

njanvilman replied to humphreymachine's topic in Anvils, Swage Blocks, and Mandrels

The paint appears to be original of your anvil. Leave it as is. If there is a weight marked on the anvil, it will be stamped in, on one of the sides, usually near the top. I will check your dimensions against a similar anvil in the Fisher & Norris Factory Museum, and will look it up from the literature I have. Answer will be posted in a few hours. The four 1's and S are internal codes used for quality control at the foundry. -

And as you probably figured out, 199 lb, and made in 1916. Nice find.

-

Interesting new FISHER added to the Fisher & Norris Factory Museum: 90 lb, 1915, custom made with the mounting lugs. This is the first Fisher anvil to turn up under 100 lb that has the mounting lugs. Someone wanted the 90 lb size, but with the lugs. So Fisher made one.

- 658 replies

-

- Cast anvil

- Fisher & Norris

-

(and 1 more)

Tagged with:

-

Anvils: A beginner buyers guide

njanvilman replied to Everything Mac's topic in Anvils, Swage Blocks, and Mandrels

Actually UPS will ship up to 150 lb via UPS Ground. Not cheap, but doable. -

Armitage, Mousehole, late colonial? ID please

njanvilman replied to PT smitty's topic in Anvils, Swage Blocks, and Mandrels

The 1 0 9 or is it 1 0 19 refers to the weight it was when made. 1 0 9 would indicate it was 121 (or 131 lb). The anvil is an English made anvil, though it is almost impossible to know which of about 300 different makers might have made it without some of a name showing. The anvil was made up of many parts: all 4 feet were forged welded on, along with the horn and hardy end. The anvil could have been made of 7 or more pieces of wrought forge welded together, along with the steel faceplate also forge welded on. -

I would never drive any oversized steel into the hardy. You are looking at getting it stuck in the hole, or breaking off the end of your anvil. Just heat and hammer it until it fits. File or lightly grind if needed for final fitting.

-

Another Help With Anvil Purchase

njanvilman replied to Travv801's topic in Anvils, Swage Blocks, and Mandrels

1 0 6 on the weight = 118 lb. 1 x 112 + 0 x 28 + 6 = 118. As to the price, make your offer. Bring cash. All they can do is say no. -

AIA says 1913.

-

You should start a few thread and post photos.

-

According to Anvils in America, Late 1912 - Early 1913.

-

If the anvil passes the rebound test, and has no hidden damage, buy it. Remember, if you can haul it, you will save $$. And what is your time worth. If this anvil will suit you, buy it. Trying to save a few bucks now and having to spent lots of time hunting for another is what you also have to consider.

-

Most 1870's Fisher anvils only had the Eagle logo. A few had FN under the horn, standing for Fisher & Norris, the original owners of the company. They did the FN on some anvils from the late 1860's to 1879.

-

Straight horn FISHER anvil, proud Eagle with the Naval Anchor. Your anvil was made between 1871 and 1879.

-

Sher, Shea or sheb anvil dated 1896

njanvilman replied to Frank1967's topic in Anvils, Swage Blocks, and Mandrels

Fisher anvil, made in 1896, in Trenton, NJ. Rough shape: missing mounting lugs, the steel plate originally on the horn, the back part of the anvil from the hardy hole. The anvil obviously had a very hard life. But I am sure lots of things got made and repaired using it. Since the anvil has a family history, to you it is priceless. I would make a brass tag and stamp in its provenance and glue it to the anvil. History is often forgotten over the generations. -

Sher, Shea or sheb anvil dated 1896

njanvilman replied to Frank1967's topic in Anvils, Swage Blocks, and Mandrels

Adding pictures would make all the difference in the world.