-

Posts

47,070 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Frosty

-

Welcome above, glad to have you. There is a regional organization section if you scroll almost to the bottom of the Iforge front page. Or you can wait and see how many folk respond now. There are a few in Kentucky or so I hear. Frosty The Lucky.

-

I saw some winter on the news but we got less than 1' all winter. I'm getting to where I could get used to winters where it's warm. Frosty The Lucky.

- 32 replies

-

- propane

- blacksmith

-

(and 1 more)

Tagged with:

-

Just joshing you, I know about getting driven in by weather. Frosty The Lucky.

- 32 replies

-

- propane

- blacksmith

-

(and 1 more)

Tagged with:

-

Get HAMMERED Oct 23-25 2015 (Australia)

Frosty replied to Dale Russell's topic in Events, Hammer ins, Where to meet

Isn't there a law in California against using anything but unbleached white? Frosty The Lucky. -

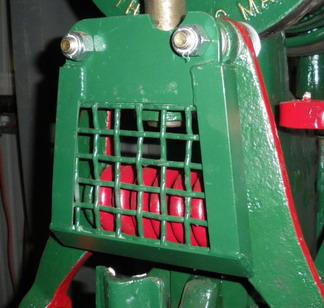

That looks the same mechanically as mine though uses a different mechanism. Is that an oxymoron? Anyway, it looks to be hooked up correctly. You can adjust the brake with the turn buckle tie rod end on the actuator arm side. The right side as you face the hammer. Not being able to lay hands on it or watch it run; it looks to be within adjusting range to me. Frosty The Lucky.

-

Exactly! "Do you have any of his tools?" Is my stock answer to the old, "My Grandfather was a blacksmith," statement. Some can be pretty obnoxious telling me how someone else does IT. I've never had a taker when I offered them the hammer. A spectator has to be pretty obnoxious for me to do that though. My Great Grand Uncle Bert Hickson was a Railroad and lumber mill millwright. I must be doing something wrong I don't feel qualified for either in any way. Frosty The Lucky.

-

See what I mean? It's only the crazy ones. You can move in next door to me any time Steve. BBQ. Mmmmmm Frosty The Lucky.

-

No worries Neil, I was a little flip with my reply. I've had this conversation so many times it gets to me once in a while. Michael, I know where you got the idea, you even said you watched a lot of Youtube videos. I was pointing out less clearly than I should have that there are GOOD sources of information. The internet is filled with how to stories posted by folk who are trying to figure things out. There's an normal reflex to identify with folk at our own level. It's a lot easier than following folk that are more advanced. My technique of instruction is to make a statement and give an explanation. If someone doesn't understand what I mean just say I don't understand . . .X "I don't know" is fixable. Wayne's site is a go to for proper forge building instructions, data and materials. Wayne and I only have different brands of supply available we don't really disagree about these things. There are a lot of different good ways to do it. Unfortunately all to much of what you see on the web is BS. A soup can forge works well with a single roll of ceramic blanket but it wears quickly. Frosty The Lucky.

-

Heating a already quenched-then-tempered alloy steel

Frosty replied to nhoshi1's topic in Heat Treating, general discussion

I don't believe the OP actually knows what he's asking for. There are so many different ways to apply a hard face suitable to things like bushing guides, etc. Baking on a powder coat, spray or sputter deposition are two more, heck electro plating, sleaving, etc. This is old well established technology, just order it hard faced from the manufacturer. Trying to do it after market is unlikely to be successful seeing as you have no idea how or even what you want beyond specifications. Also doing this after market will void any and all warrantees from the original manufacturer. Frosty The Lucky. -

I've started sending error messages to Charlie at IPS with a request for an explanation. I just sent off one that said there are no messages in the "It Followed me Home" thread just because there are 176 pages of posts doesn't mean there's anything there. Charlie started sending me nothing but boiler plate responses saying all the issues have been addressed or resolved. I don't know if filling his/er inbox with complaints and examples of their lack wit software will help but it's some satisfaction. I posted my email address in the "found some issues or problems or whatever" thread if anyone wants to ask offline I'll send you Charlie's email address and we can help share the pain with her/im. Frosty The Lucky.

-

Binding Gold to Iron from meteorite

Frosty replied to LuftWaffle's topic in Blacksmithing, General Discussion

I think that's a pretty good idea but (yeah, there's almost always a but <sigh>) pouring molten gold on the meteorite iron would probably destroy the . . . Uh . . . What Thomas said pattern. I think electro plating would be the way to go. Mask what you don't want plated and preserve the patterns. Probably be best to have a pro do it, there's a lot of preparation and several steps involved then there's the HazMats to dispose of. Frosty The Lucky. -

That was weird, I have Google set as my default search engine, I guess Windoz looks for the one with the most hits or maybe what the IT in mother's basement likes or . . . Using the oars as the legs is almost a given if there isn't another theme. I forgot the mast entirely, the spars could make nice roasting spits as well. I like to stand rectangular bars on edge to make grills but 3/8" x 2" is way too deep for grill bars. This sounds like a really nice project, I look forward to the pictures. Frosty The Lucky.

-

Have you searched, "Forged Dragons?" I did and got so many hits I only scanned the first couple pages. This was the third one from the top. There were several how to's on the first page as well. This was just too easy, you're lucky we don't charge for doing the obvious for folk. https://images.search.yahoo.com/yhs/search;_ylt=AwrTceDuSaVV0xcAEr0nnIlQ;_ylu=X3oDMTByNWU4cGh1BGNvbG8DZ3ExBHBvcwMxBHZ0aWQDBHNlYwNzYw--?p=Forged+Dragon+Head&fr=yhs-mozilla-001&hspart=mozilla&hsimp=yhs-001 One thought for the long ship brazier, if it were a fish or fork tailed dragon you could place a spit between the dragon's horns and a shapely spot on the tail to BBQ roast tasty things. Frosty The Lucky.

-

Most of us have dealt with practicing the craft and accumulating tools, materials and enough shop space while dealing with a paycheck job. Heck, we only just recently rehomed the last of our livestock but got a reputation for socializing new and newly weened lambs so our old pastures get mowed. Anyway, we've all dealt with only getting to the shop when we can. You already fit in here. What kind of forge are you going to build? Frosty The Lucky.

-

Welcome aboard Michael glad to have you. If you'll put your general location in the header you might be surprised how many of the IFI gang live within visiting distance. Sure you can use that type plaster substitute. Are you patching nail holes in your walls? Spackle will work better but if the budget is tight enough even white tooth paste will work. If you're talking about making a propane forge, don't be silly, read more. You need a refractory liner not plaster of Paris. Have you ever tossed a piece in a camp fire? A camp fire is pale by comparison to a proper forge, say around 1,400f while my home made forge melts 3,000f fire brick. You can buy good quality castable refractories and if you consider how long they last compared to light fire brick it's a bargain. I used Green Cast 94 for the floor and rear wall of my current WIP gas forge. A 8lb. ceramic blanket, say Kaowool for instance will take about 2,600f and is a good insulator but is darned fragile so you need to kiln wash it or just get used to changing the inside layer pretty frequently. There are lots of good methods of lining a kiln/furnace, there are many books about it and while Bentonite clay AKA kitty litter is a viable refractory I've never, not once seen plaster of Paris mentioned. There are hundreds of posts here about building propane forges, pull up a comfy chair, pack a lunch and something to drink, there is a LOT to read on the subject. Frosty The Lucky.

-

Piker. Frosty The Lucky.

-

Hey Guys: I don't have so many friends I can afford to lose any. If you have to try to figure out how to take brake cans apart you are NOT qualified to try. These things KILL people who know what they're doing if they get just a LITTLE complacent. Why don't you do something sensible, say over heat some O2, quench it in brine and then forge it without wearing safety glasses? LARP Frogger wearing black on a freeway at night? Come on guys you're making me wonder about your sense here. Frosty The Lucky.

-

Binding Gold to Iron from meteorite

Frosty replied to LuftWaffle's topic in Blacksmithing, General Discussion

Welcome aboard, glad to have you. If you'll put your general location in the header you might be surprised how many of the IFI gang live within visiting distance. Jim Binnion has diffusion welded iron and gold. Tell him Frosty says hi. Mokume Gane - DOT - com You'll have to search his site out, it's a commercial site and posting the URL is against site rules. If you tell him Frosty sent you he might not ban you till the heat death of his cocoa. It ain't easy for someone who's experienced and equipped, just so you know it is NOT a beginner's mokume gane project. Frosty The Lucky. -

Who is crazy enough to complain to Steve? Frosty The Lucky.

-

Heating a already quenched-then-tempered alloy steel

Frosty replied to nhoshi1's topic in Heat Treating, general discussion

The coating is abrasion/wear resistance rather than hard like a rock compared to putty. Buy it coated fro the manufacturer or have it done professionally. Frosty The Lucky. -

It sounded like YOU were lonely, if there were a LOT you wouldn't need to ask you know. Frosty The Lucky.

-

I know how you feel but life is what gets in the way of our plans. You'll have to wait till next year because your in Canada? Does it close or something? Frosty The Lucky.

- 32 replies

-

- propane

- blacksmith

-

(and 1 more)

Tagged with:

-

Yeah, like the IPS staff cares enough to check how the forum is working. I'm just going to make an annoyance of myself to them, I strongly doubt it'll make a difference but it's a way to share the IPS experience. Frosty The Lucky.

-

I've seen that before too now you mention it. I YELL HARSH INVECTIVES at anyone who even LOOKS like they're pointing a chisel at the step on one of mine. Of course I'm a cranky old fart and use my steps for other things. Frosty The Lucky.

-

Here's what I put on my 50lb. LG. The first pic is from the front, the brake band and arm are red. when I get around to rebuilding it I'll make the band cover more of the crank plate so it stops more crisply. The brake pad is an old leather belt. The second pic shows the lever that converts the downward motion of the treadle into a lifting motion to release the brake. The treadle clutch spring applies the brake when you let off the treadle. More brake band would be better, there isn't a lot of spring tension. The third pic shows how I mounted the static or anchor side of the brake band. I just used longer bolts on the bearing caps because I'm a lazy guy. It was ENOUGH work drilling and tapping the hole for the pivot on the brake lever! The last pic is the spring scatter shield. I painted red, all the potentially dangerous moving parts OR the ones to pay close attention to in a pre-use eyeballing. I used the grizzly screen in the guard so I can visually inspect the spring. The paint is an important safety feature where metal fatigue is a factor. Paint doesn't stretch NEARLY as much as the sides of a crack or failing weld. If you see pealing paint on a piece of machinery take a CLOSE look at the spot it may be getting ready to fail catastrophically. It's easy to see the back side of the spring but I wanted a window on the front too. If it breaks in use the screen will stop or deflect the pieces and I'll be several steps away before it hits the floor. Frosty The Lucky.