-

Posts

2,136 -

Joined

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Chris C

-

I got lucky with this Anvil!

Chris C replied to Scooter430's topic in Anvils, Swage Blocks, and Mandrels

WOW, Skooter, I think that's the best "find" I've seen in the 15 months I've been pretending to be a blacksmith. -

You guys are unmerciful today. My mind is on a million other things. Forklift Tynes........or forks, which ever you want to call them. Just don't screw up and call'em tongues or someone might brand your tongue with a hot tong. ! This is gettin' down right redickeweluss!

-

Whoops! Pardon my ignorance.

-

-

I have one of his with the upside down warning sign. Oh, and I might add, there were 4 forklift tongues there if anyone is looking to make an ASO !!!!!

-

-

No sir, just bare hot-rolled steel. I chipped off some paint with the tip of my pocket knife at the salvage yard to check. Guess I could go further and put paint remover on it to double check, but I really see no reason to do so.

-

It's painted, Frosty. Checked that for sure.

-

This is for all of you in the Oklahoma City area who are familiar with LA's Recycling. (only ones I know of are DHarris and Picker77 Was looking for some 3/4" rod to use in tong making. Came across this container with a bunch of it. This is what's inside the container. Weighs 13.5 pounds. Cost me $5.15 with tax. The long arm is 60" and the support arm is 35". If the material is any good, it ought to make quite a few pair of tongs.

-

Very sorry to hear this, Thomas. I can't imagine what you must be feeling. My prayers are with you, Brother.

-

Looks like a good start.

-

As I said, I'm no engineer.............and much of what I do when building is to over build, but I think you can't over-do on the baffle.

-

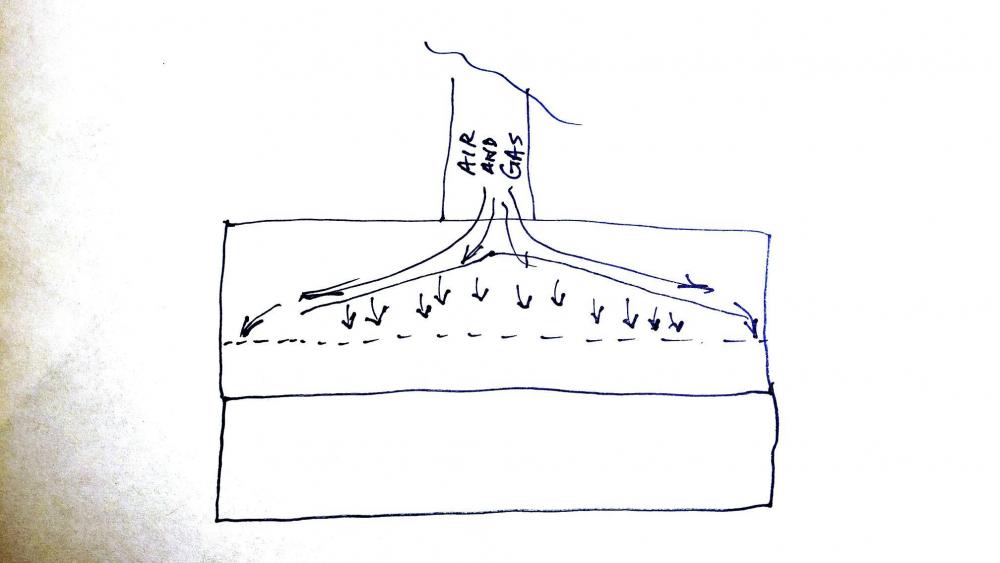

It would still allow gas and air to enter the burner box.........................but it wouldn't divert those materials towards the ends of the box to evenly distribute them to the entire burner face. It might be over-kill, but I believe many people would agree it's important to get the entire homogenized mix out to all the holes in your plenum. Here's a very poorly drawn sketch of what I'm talking about. My baffle goes all the way across the box but only covers about 2/3rds the length and is filled with random 1/4" holes.

-

Well, thanks to Picker77, I came home with 4 window weights for my chain hold-down. Thanks Picker!

-

Long awaited addition to the shop.

Chris C replied to Irondragon Forge ClayWorks's topic in Building, Designing a Shop

No need, but thanks for the offer. -

Long awaited addition to the shop.

Chris C replied to Irondragon Forge ClayWorks's topic in Building, Designing a Shop

Thanks, Jennifer. Gittin' old ain't fer sissies! -

Long awaited addition to the shop.

Chris C replied to Irondragon Forge ClayWorks's topic in Building, Designing a Shop

My word, IFC, you're one old geezer! I turned 75 today, so you're closer to the Pearly Gates than I! -

I put a baffle inside mine. It was an upside down wide v-shaped thing...........kind of like a wing. My understanding was it helped distribute the gas/air mixture toward both ends of the burner so the mixture didn't just go straight to the middle of the burner. I'm no engineer, but all I can say is my burner worked flawlessly from the first firing. Very happy with it. This is a short video of my first firing. So I vote for the diversion baffle inside the burner.

-

PM sent. THANKS!!!

-

Thomas, the helical twist at the top isn't so bad. It's when it reverses itself toward the butt end of the handle that poses the problem. I may actually trim that bulge down a little, CGL, but for right now I think I'll just make it a permanent handle and go with it like it is.

-

Well, as an experienced woodworker, I k now about distilling woods for their oils. Just didn't know Camphor was a wood.

-

I didn't realize Camphor blocks were distilled from wood, Thomas. Learn something new every day. I have an old wooden Gestner machinists tool box. It's not made of Camphor.

-

-

Tristan's RR anvil with clamp

Chris C replied to teenylittlemetalguy's topic in Anvils, Swage Blocks, and Mandrels

That's an absolutely ingenious solution to your problem, teenylittlemetalguy. -

Well I made the handle. The head end of it is sitting in a cup of Boiled Linseed Oil. I'm kind of embarrassed to show it to anyone. Doesn't look anything like any blacksmiths hammer handle I've ever seen. On the majority of Dog's Head Hammers it looks as if the maker used a "Tomahawk" handle..........just straight. This looks more like a carpenter's pin-nail hammer with a thinner neck. I've always liked thinner necks on hammers because they allow the head to whip a little and they also don't seem to transmit vibrations back up the arm to the user, which I believe contributes to what many call "Blacksmiths elbow".........or Tendonitis. Of course, that's just my (uneducated) opinion. As good as the handle feels in my hand, I think I'll post a picture of it before actually installing it to see if there are any "no-no's" I've committed. Originally I was going to shape the handle on my new belt grinder, but I didn't have a belt that did well with wood, so I used what I'm most skilled with, knives and a spoke shave. I like the faceted surface and only hit it lightly with a 220 grit 3-M pad to slightly soften the facet edges.