-

Posts

455 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by 671jungle

-

What type of steel are big rig brake drums made of ?

671jungle replied to ah1988's topic in Blacksmithing, General Discussion

did you ever do anything with this? I capped a log with one and use it to mount tools and bending jigs. the local recycle center gets them frequently. -

this beauty will be following me home tomorrow. I am extremely excited! It will be my first piece of genuine blacksmithing equipment. $200 localish pickup. From the looks of the pics of the shop and the Ad post, there might be some history I can dig up. I will post more pics when i get it. And enter it into the "Show me your vise" thread once its cleaned up and mounted. I have not been this excited about anything since i first started jiu-jitsu 15 years ago. Like learning new moves, acquiring new equipment and the skills to use them is just as satisfying. I will still build the vise out of the bushhog blades for camping trips and such.

-

Brother-in lawish brought this home. I know some here appreciate books. The original 1804. The pages are folded back toward the spine. He also scored a few other old ones. This stood out.

-

-

-

Coming home with today. A friend works for maintenance on one of the ski resorts and gets all kinds of hardware. This is one the cable bracket thingys. Not sure what it could be used for but it’s pretty cool

-

4140 Cracked when hardening

671jungle replied to Ancientsword's topic in Heat Treating, general discussion

this is impressive. I had no idea silver solder could be used for heavy applications. I can imagine the impact and torque at the teeth and silver solder will hold it together!? -

Picked these up awhile back. The bare one didn’t follow me home. It is 30ish lbs of 4140 I got online for $1 a lb. The other was found in the metal bin up in park city recycle center. It is 20ish lbs. probably make some good stump/stake anvils?

-

Good to know a reuse has been done in one way or another. This is what the singer treadle will used for:

-

Some big chunks bit out of this head. I was going to dress past the divot but I feel that would take too much material off. Also the file eats into it easily. Would that be a problem? I wire wheeled it and found what looks like forge scale. ideas on how I should proceed? I just want to use it. It’s so pretty.

-

I rescued these two from the metal recycle bin in park city today. The singer wheel will be incorporated to my hand cranked leather cobbler. I plugged the lathe in and it runs! Smooth! cant beat free!

-

A collection of improvised anvils

671jungle replied to Charles R. Stevens's topic in Anvils, Swage Blocks, and Mandrels

I went with this design. More mass under the work. I have thrown about 75lbs of chain on it and it only rings when hitting flat and it is not that bad. I have ground out a hot cut and some curves since this photo. It has worked well, and have made other tools as the needs pop up. An actual anvil would be nice but this is fine for my experience level. -

Lol, got it. I won’t change her. Didn’t know these were coveted. Thank the gods for saving this hammer from my ignorance. I ran a file across her and it bit. Could it have possibly been annealed? maybe dress her and heat treat? I’ll send it to you for free! It is the least I can do for all the knowledge you share. I’m still pretty amateur, I would butcher the “good tools”.

-

Thank you all for the great tips and ad(vise)! what if we weld the angle iron to the ...legs(?) providing extra thickness and a shield? Then thread through both to mount the jaw bites? I appreciate all the input. Blacksmiths will rebuild the world. I am also wondering if the bend in the blades will be an issue. If they dont hold up it would be an easy change to truck leaf springs.

-

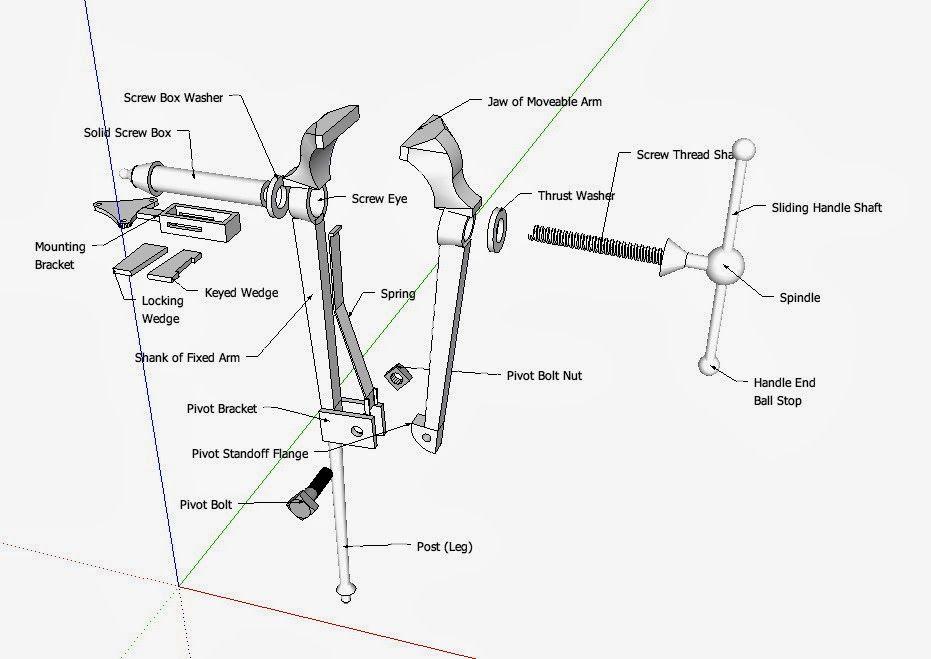

I may just upset the end of the screw and punch a hole in it to accommodate the sliding handle. As for the jaws, maybe some angle iron fitted on both jaws to make the biting part. I dont want to add too much meat to the jaws. The workpiece should stay above the mass of the jaws as much as possible while providing a good bite.

-

Still needs tweaking. Like some sort of jawing. And definitely a better handle. Gonna get it welded up in the next few days. Including the the jaws flush against the square tube, maybe just bolt it? And put a sleeve on whatever screw it gets.

-

So... kinda made a vise. Base: solid block of steel will be welded to square tube. Jaws: bush hog blades will be resting in groove cut into solid steel block. Maybe they should be more secure? Maybe secure the stationary jaw like in traditional postvises? They won’t have an over hang. I’m sure that need will surface at some point. The screw and screw box are from a overkill bar stool. I still need to figure out a handle. The screw can be replaced by any I guess. I put some metal in it and gave it a few whacks. Even though it is not glued together yet, it took the blows like a champ. a couple photos with different box configures

-

Thank you. this site has done a good job at letting me know if something is in my range or not and has been extremely helpful in acquiring and fine tuning skills.

-

I would like to see as well! thanks!

-

Railway track hot cuts

671jungle replied to Joel OF's topic in Hot Cuts, Anvil devils, metal cutting on the anvil.

I just redressed my upright railtrack anvil with a hot cut built in. not sure how well it will fare. It is from the Loraine Street Railway. Later renamed the Cleveland, Lorain & Wheeling, it would be absorbed by the Baltimore & Ohio Railroad in 1909. manganese steel (mangalloy) was created in 1882 and was used widely but not much info on who used them for rails. Mangalloy is funny stuff. -

Found in the metal bin a few months back. I need a ball peen, would it be worth turning this into one?

-

I am in the beginning stages and still learning quite a bit of the basics, enjoying it all. I dont have much time and funds to learn in a proper shop with experienced smiths which would accelerate my learning curve. But I dont mind making mistakes, I've made a lot. Just dont want to make too big of one. I have learned a ton from this site over the last several months. Enough to confidently build an efficient enough forge and burner of various sizes. This project might stay in the corner until the opportune moment or it gets used as something else. I am now making punches and other striking tools but need a vise to hold the work. A vise is imperative to further my learning. I do have other materials to make a much simpler easier descent hold. I may resort to that. I saw the potential in the rails and know it is a simple design but a monster (fun) project. I lack the experience to take that on alone and blind. I will want to make one someday. Thanks for the advice on the the tool steels. It would be a dream to come across some S7! all the punches and cutters i have made so far have been made from strut springs and have held up nicely. I also have a couple bush hog blades that might make a nice durable hold using the forklift tine design. that seems a little more in my ballpark and my girlfriend (who aint no slouch) could help with the swinging. I have a giant brake drum that could be rigged as a vise to hold the tines for forging. lol, Im all over the place.

-

I do not. And I do agree, it is quite an advanced project. I am not in any rush and dont expect it to look pretty but it is important to me that i functions well. Im sure it'll take awhile till it takes form and maybe i will come across an antique in the meanwhile. I saw all the pieces sitting next to each other while daydreaming and thought they would work well. I also need a reliable vise. A little of both at this point. Have not racked up the experience to know. I've always been a maker and making the tools to make other things is satisfying thus far. I dream of making rails and gates and things to take to BURNING MAN! lol I am currently reading this thread

-

Not much! I intend on visiting some of the shops around here and make some friends. If help is scarce, I have a sledge and a couple of willing swingers. I can build a temporary forge for this project as it is the largest I will attempt for awhile. I do have some friends that weld although I don't think much welding is needed if i use the webbing as the pivot bracket. I will also build the tongs to handle the jaws for upsetting and forging. It looks like the screw and screwbox assembly on most antiques fits at the ends as an insert of some sort? Maybe a slotted rest? This is the basic plan for the most part. I am learning all along the way. All advice is welcome!

-

having a 3rd hand that can handle a beating is crucial. Since I am new to the fabrication world, instead of buying an antique (which would be super sweet!), I am going to build my own post vise. The plans are simple enough. Any advice from the Elders before I begin? I would also like to punch the holes for the screw instead of drilling. Speaking of screw, the one in the pic isn’t the chosen one. It is just a standard 1”. Will it work? And the tallest rail is about 21”.