-

Posts

455 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by 671jungle

-

very nice. is this a menu for customers to choose from? Nice Saws!

-

You have done good Mike.

-

Is there a way to retrieve these photos? Is there a list elsewhere?

-

What did you do in the shop today?

671jungle replied to Mark Ling's topic in Blacksmithing, General Discussion

previous post was in response to Billy -

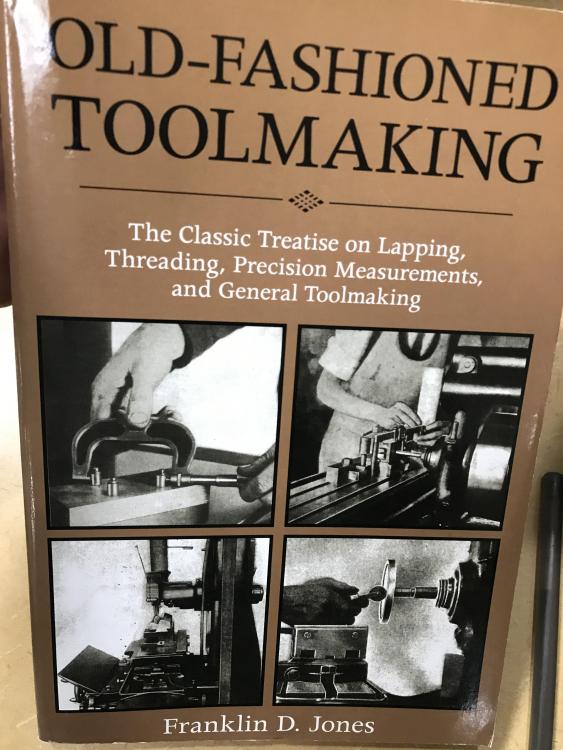

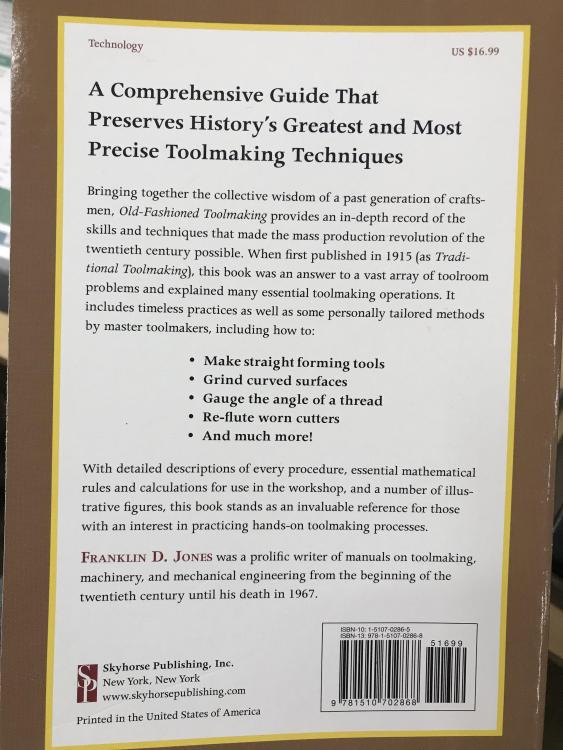

Hard copies run from $50-almost a grand!

-

What did you do in the shop today?

671jungle replied to Mark Ling's topic in Blacksmithing, General Discussion

I was wondering who was gonna step up! I just don't know what the upgrade from the rail anvil will be so I left a little on the top. Speaking of anvils, I may have a lead on some forklift tines and large axles from a couple of rental and repair shops. Trying not to pay $300 for a 100Lb chunk of 4140 from the steel supply. As for what i did in my yet to be built shop: a fairy dagger. My Love and I are going to New Orleans for Halloween as Tinkerbell and Rufio from "HOOK". Tink wears a dagger on her leg. The blade was forged from a coil spring. -

What did you do in the shop today?

671jungle replied to Mark Ling's topic in Blacksmithing, General Discussion

As far as results, I dont see any ring rust. Your skills speak! And its all good! Technique is like riding a bike. Once learned it sticks. Muscle memory usually makes for a speedy comeback unless injured. After using the rail anvil for a bit and learned a bit more hammer control it was time to make it more useful. Lefty?! Me too! It has its advantages. -

What did you do in the shop today?

671jungle replied to Mark Ling's topic in Blacksmithing, General Discussion

Started leveling the ground for the shop. Dimensions 6’ X 14’ with stump as base for anvil. Will be equipped with 1 man door and 1 swing up door. Thanks to Thomas Powers for suggesting garage style doors on other threads. I also redressed the rail anvil similar to Charles R Stevens set up. Thanks Charles. Nice! Do you carve? I would like to carve a totem pole some day. Quick Question: What do you use the side shelf protruding from the anvil for? -

What did you do in the shop today?

671jungle replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks for the tips JLP. Btw, I really enjoy your instructionals on YTUBE. Very helpful for a beginner with no teacher. Thanks Aus. You do some sweet work! I actually have a son (7yrs) who is pretty interested in almost everything i do. We have already made a small blade together and are working on a prop jet pack. Most forging is on hold until the shop gets built. That is a beast. upsetting would be nice in that. -

What did you do in the shop today?

671jungle replied to Mark Ling's topic in Blacksmithing, General Discussion

Sorry, having issues with posting. Nice bracelet. That was my initial idea. JLP do you mean the bracelet looking thing that seats the bearings as good knife/chisel stock? Thanks for the responses! -

What did you do in the shop today?

671jungle replied to Mark Ling's topic in Blacksmithing, General Discussion

Finally got the tree down. Windy day made it scary. Can finally start constructing the shop. I also pulled apart my first cv axle. I think that’s what it’s called. I must say, the parts are pretty cool. What does one do with them? Could the housing hold up as a dishing tool? -

beautiful work, whoever made them.

-

What did you do in the shop today?

671jungle replied to Mark Ling's topic in Blacksmithing, General Discussion

-

What did you do in the shop today?

671jungle replied to Mark Ling's topic in Blacksmithing, General Discussion

I am also afraid of heights. The cold front we are having is preventing me from finishing this tree where my shop will go up. I too am shaky up to about 50ft. Captain Fraver (fighter pilot who saw ufo) said at 2,000’ or 20,000’ the ocean looks the same. That ladder angle in Alexandr photo is deceiving. -

Strong point. In the beginning competition will be fierce. Good thing most of us here (IFI) know how to scrounge. My father was/is a scrounger and used to take me to the junkyard and turn me loose with a couple wrenches while he ripped out whatever he was looking for. The ability to identify an object in a sea of mangled clutter is learned in places like this.

-

This speaks to me on levels. It is because of teachers like you who understand change and are willing to pass on knowledge and lessons to a non-traditional audience that people like me (jungleboy moved to the city) have some kind of primal outlet. I believe the skills of the smith and other builders are something that must be preserved for when the rebuilding is needed. I also wonder on Traditional vs New Age. After all wasnt everything "new Age" at one point or another?

-

Thanks for the input Y'all. I do prefer to not compromise the integrity of the post by slicing into it. I will have to ponder a bit. Great suggestions. This forum is great!

-

Thank you Glenn. I was planning on using a jig. Thank you Charles that is a great idea. I do have a newly acquired I beam and a whole lot of 3/4” and 1/2” all-thread. I may go that route.

-

going to start building in the coming week with a dirt floor or end grain floor to simplify construction. However I would like the post to rest 1/4" above the buried to ground cement buckets to reduce rot. I was thinking about bending some flat the width the of the post into a U. Any ideas? The anchors at the store are pricey.

-

Lol. I totally thought that was graffiti.

-

Thanks for replies! The B26 lacks the swollen cockpit. The P2V Neptune however looks to be it. Swollen cockpit and the little window on the nose. The pic I posted seems to be painted over.

-

Kinda literally followed me home. Headed down Parley’s Canyon UT this semi was hauling the front fuselage of some old plane. I see all kinds of stuff on this highway, like this Corolla sized tree stump! Huge heavy equipment for The Kennecott Mine also always being towed. Anyone know what kinda plane that may be? Seems WWII era.

-

-

-

I do not have a hardy hole. To resolve this I am going to use a drive shaft with the flange mounted to a base/floor. Use a 1 1/4" impact socket with a 3/4" drive over the splined area and use the drive as the hardy. Some shaping might be needed to get a nice fit over the shaft end. the hardy tool will be kept secure while still transferring energy directly to the shaft