-

Posts

5,798 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by jlpservicesinc

-

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

So last forging day before heading off. Samples plenty. First horse heads. Middle 1 is #3, Figured they would be a welcomed beginner project. The 3rd one looks decent.. Still have to work out the little details I'd like to add. Like getting a proper ear. Trivets, nails, hooks, and tool steel/heat treatment, will be covered in the class. The Tulip hook is rather intense for beginners. Will have to see how the students are. Super excited. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

thank you again.. Our inflation rate is pretty high right now, so the dollar will not buy as much as it used to either. Forged this small Tulip hook today. More class prep. Yes JHCC nothing political.. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Very reasonably priced now. You'll have to get more paying gigs and stash the money away for a new tool. "We agree on a price with the customer. I don't have any calculation formulas. I try not to offend myself, and not to scare the customer away. I don’t pay rent, I have my own workshop, I don’t have hired managers who need to pay salaries. We try not to pay taxes))), only for those payments that go through officially. If workers are hired, they are usually paid piecework. Percentage of the total cost." Alexandr Thank you.. Being that I'm from the USA and have limited travel abroad I am always curious as to what the wage is for a given item or work.. Really I'm just interested in what people do and how they make a living. It seems all over the world it's about the same. Try to do great work for a decent pay.. Thanks -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

You guys are too serious.. it's all a joke.. Before too long, I'll probably be propane myself. I dread that day. Solid fuels are so precise heat-wise. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Wow, you have converted over to the dark side. Sadly with the way the coal mines aren't running these days it's probably the wave of the future. Unless of course, someone has ample time to make charcoal or other biomass-type fuels. Going simply by today.. The heyday of soft coal is in the rearview mirror. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Alexandr that is fantastic. I still don't know how you do it alone.. Your production rate is off the charts.. If you don't mind me asking.. what do you charge per hour or shop rate? I did some forging today in prep of Peters valley. Few show and tell items of possible class materials. JHCC.. Lots of finer and finer sand paper. -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

Bummer. would have loved a visit.. Been a few years now since the last visit. Hopefully next time.. Of course, by then I hope the school will be near completion. -

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

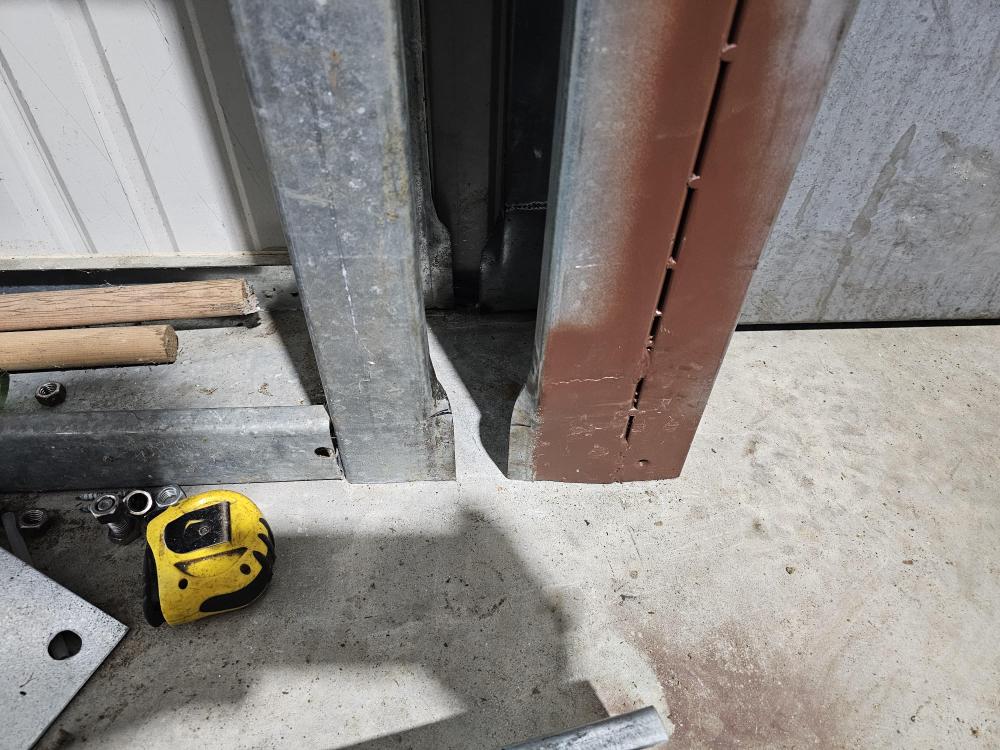

Thanks. it's going to be spectacular when things finally get finished. LOL.. 3 years of a wild ride for sure. Huge, huge learning, and many curves to boot. Many do and redo's. Also all the learning about the support equipment like the manlift.. Which I love, love, love. Back in 1986 my stage fright was pretty intense. If I stopped and looked into the audience I was a mess for about 5min until I could get back into the swing of things.. Swing of things.. get it.. Talking to the audience was ok.. But no looking. Now, I don't really see a difference. People there or not there.. Interestingly while I don't talk much on the videos it's simply because there isn't really an audience. What I mean is, the flow of having people hanging and watching is not there. Often times I explain things while forging or during reheat times.. Reheat times get cut out of the videos. While I'm demonstrating I just explain and talk to people as I work. Comes with being comfortable with the materials and methods. Seamless really. You are welcome to come by anytime. I hope to have an open door policy with fellow smiths if possible with many hammer in's and educational events as well as some smaller group things. Onwards.. shop news I worked in the shop more. I pulled the workman door and welded on some steel framing to it so it would be solidly mounted in the wall solidly. The door was originally designed for wood construction vs metal construction so the jamb was thin.. Was impossible to mount the building trim properly.. I used larger diameter tapcon screws to and used silicone between the metal touching the floor. Now the door is rock solid.. Of course the next time I do a door I know the correct steps. I had to do a few extra things after welding the frame on like putting bolts thru to pull the center into a neutral position. The door I bought was adjustable which means it slides on thin metal sliders. Now it can't do that. Doing it again I would weld the sliders and put in a cross bar spacer for the correct spacing. By getting the door frame done this means I can install the insulation and interior siding. That is a huge next step. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Shaina, Looking good. You have had some great progress. Hows the ABANA course going? Billy that is cool. Nice job. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

That's a great yorch lamp. What did you use for the torch part? -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

It's been in the mid 70 to low 90s. The humidity has been off the charts this summer with 70 feeling like 95 and 90 feeling like 100f. We have had so much rain the raspberries have little flavor. We have been getting 3 to 4 days of rain on a regular schedule meaning weekly. Only nice thing is not much risk of fires. Few days ago I finished the chain makers tongs I'll need for teaching at Peter's Valley. 3/4"sq jaws, 7/16" reins. -

Howdy, I've never been there. I did talk with Dick Sargent who was the lead there for years before the current group. Anna is the shop director and is the reason for the invite. What a great person. Swings a mean hammer to boot. I told Anna about the teaching curriculum and was then told about no chain makers tongs. Argh, electric blowers. Ick...why, why, why. I can see electric for large stock but not for general smallish work. Seems so fiddley to me. My original shop would have a stream of water thru the center so as long as there is ample work around space that's OK. I used to love the water trickling sound. "Very nice as usual" thanks. Arm and hammer swing have started to return to previous retirement ability though the dislocation does show itself. Hammer swing is starting to show the right return in metal moved.

-

I will be going down to Peters Valley to teach a beginners and beyond course. Forge welding is a basic skill so usually gets taught day 1 or 2. Where I'm going has no chain makers tongs so.. Need some tongs, make some tongs. These are a little lighter than I would make for myself but should be about right for students.

-

Please help me ID this 400lb Anvil

jlpservicesinc replied to John09040's topic in Anvils, Swage Blocks, and Mandrels

Sadly? I think this used to be the case. So many of the old examples in prestine shape have been plagued by new users with little regard for proper etiquette and slamming the hammer into the face. It's the reason I recommend buying new. Or using a hunk of steel until one learns the difference between use and abuse. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Also gave a lesson on Pigtail finial forging. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

I'll post a video with photos of the key points when I do a tutorial on the subject. The person who inquired about it was looking for alternative wrought iron jointery methods and from the description and drawings I supplied, he still could not wrap his head around it. The last time I made this style of this joint was some 30 years ago and without any of the form tools (tools used for checking measurements and such) I made back then, all there was is a hot chisel, forge, anvil, hammer, some larger 1.25" square drift I brought to change into a Cutler's hammer eye drift was able to demonstrate the concept and actually put 3 bars Upright and 2 rails. Forming a locked Cross shape. Not my finest work but was pretty excited to get it done and together with such limited equipment and time. got it completed in just about 2hours. 3/8X1" cross bars and 1"sq upright. sizes don't really matter was just demo stock. So, stay tuned. The school is coming along so hopefully the next "real teaching" video will be in there with all new digs. Had, a ton of people watching and learning about forge welding. Was nice because I was able to get some reins welded onto the tong jaws. I used different scarfing methods and explained why I like my tongs with a 1/2x1/2x1/2 ratio.. Anyhow, Had a great time, met a few new people but sadly got caught in a candid moment by one of the master smiths who is a watcher from a distance. I don't like to do those kinds of things in front of regular people. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Today was the NEB spring meet at the Bolton fairgrounds in Lancaster, MA.. A great demonstrator Dennis Dusek wowed the crowd inviting many to come up and work with him as he forged many items of artfulness. Dennis D. is the guy in the green shirt. Was Super, super humid. What a stunning smith.. His energy and excitement about what he works on was super apparent. first time at a demo where the demonstrator just had people come up and help.. Way cool. Me I made tongs giving a demo as I went along on different types of scarfs and showing how tongs should be laid out, also taught a lesson on wrought iron work invisible joinery and 1 on rattail finial. Cavpilot2k came by for a meet as well. I tried to rope him in to forging something but it was Sooooooo hot and humid. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Looks very good indeed. Sales or personal? The class is a "beginner and beyond" so is very personalized towards each student. So there is a common group skill taught and practiced, if the person shows proficiency or has the skill down, they get shown another skill building of the original shown. Tong making is not typically taught but if there is enough interest and the skills leading up to tong making are in place then it is entirely possible. The class was scheduled for 5 but was informed there will be 9 students so will have to see how the group shakes out. Might be some mini skill sessions breaking the class into 2 or 3 groups. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Got 1st set of chain makers tongs finished. 4 more pairs to go. 5prs needed for the upcoming class be taught by yours truly end of July. 3/4"sq for bits and 7/16" for reins. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Very nice. Those HF trailers are decent enough but they were designed just enough in some areas. I added 3" channel on the one I have which is a tilting unit.. At some point I will have to replace the front A as it's a weak link for sure. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

JHCC, You are freaking me out.. I'm not used to you getting the shop all organized. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

JHCC, that is a great cart for you shop. Very nicely done and designed. super handy for sure. Will you mount the gas saver on the cart too? -

3,000 lb Chambersburg

jlpservicesinc replied to RailForgeWV's topic in Power Hammers, Treadle Hammers, Olivers

I am so envious. I met one of the Hallmore guys that pulled all the machines out of the Navy shop after the auction few days ago. Of course everything happens as it's supposed to or else I would have a 1500 open frame hammer. I'm happy for you though and maybe on my journeys I can stop by and see it in action. Thank you so much for rescuing this hammer.. And also thank you for posting information about such a wonderful historical item. that is awesome. Fantastic job on mounting it.. How much clean up did it take? cosmoline and such?