-

Posts

19,312 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by JHCC

-

Well, that was 35 years ago, and I may be fuzzy on the details. The proportions are about the same, but I think Fred’s was a cross peen.

-

In other words, the force exerted by the hammer blow follows the rule for pressure: mass divided by area. A 2 lb hammer with a 1" square face and a 2 lb. hammer with a 4" square face will both hit with the same total force, but the hammer with the smaller face will have that impact concentrated on an area 1/4 the size of the larger.

-

It's a thing-holding thing.

-

That's "Authority Having Jurisdiction", FYI.

-

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

I've started a new discussion on Hammer Shape and Its Effect on Precision; let's continue this discussion there. -

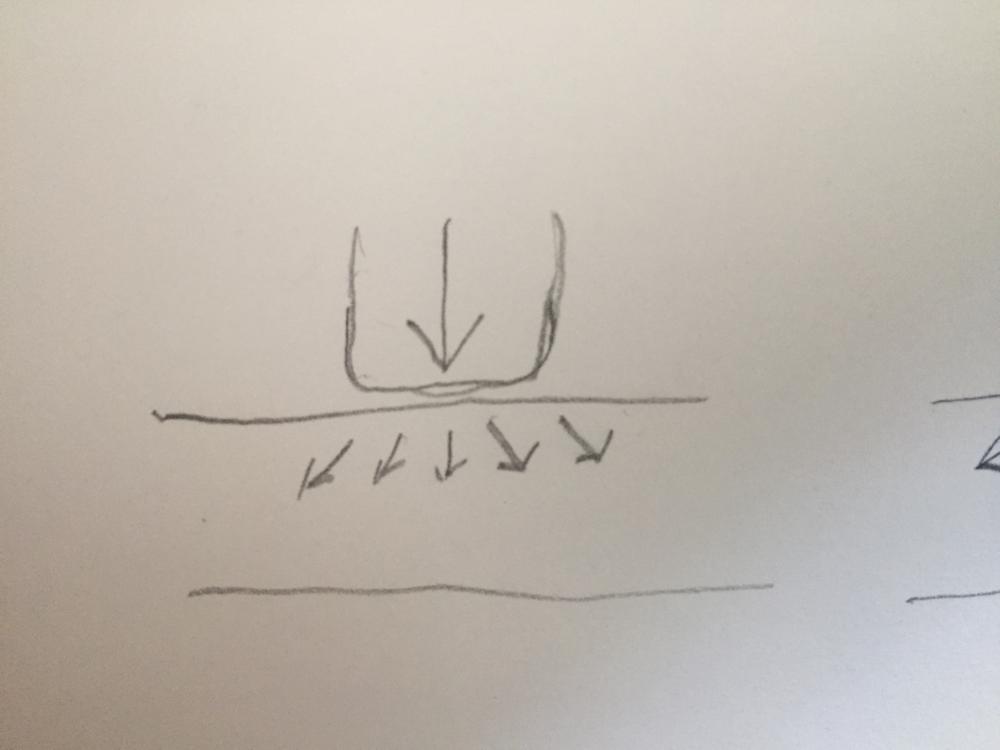

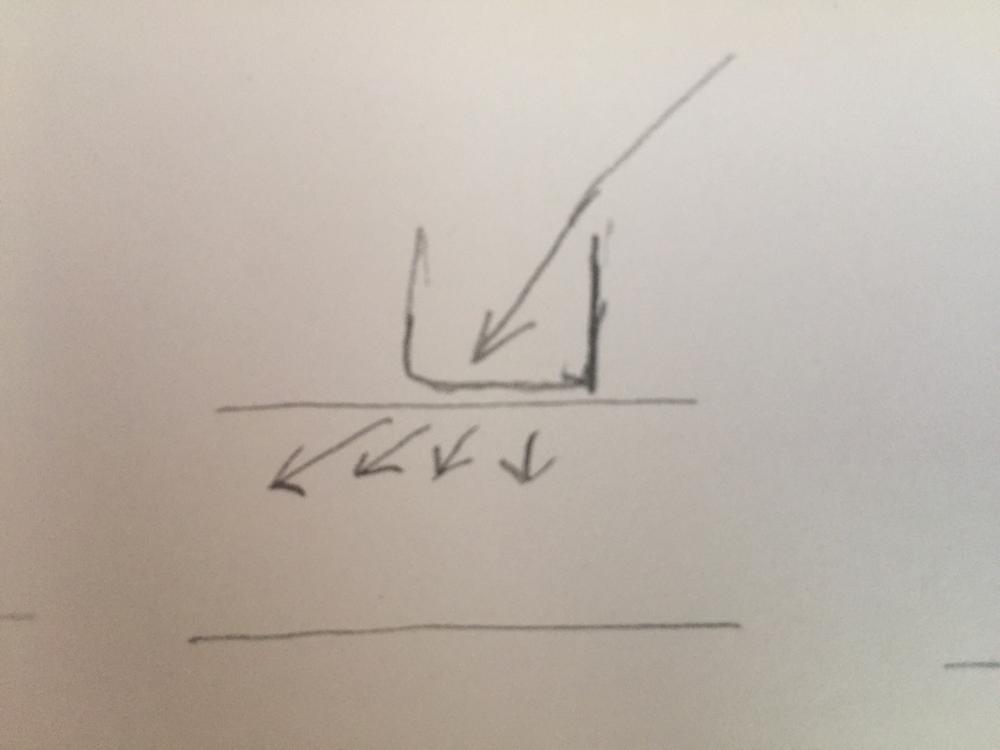

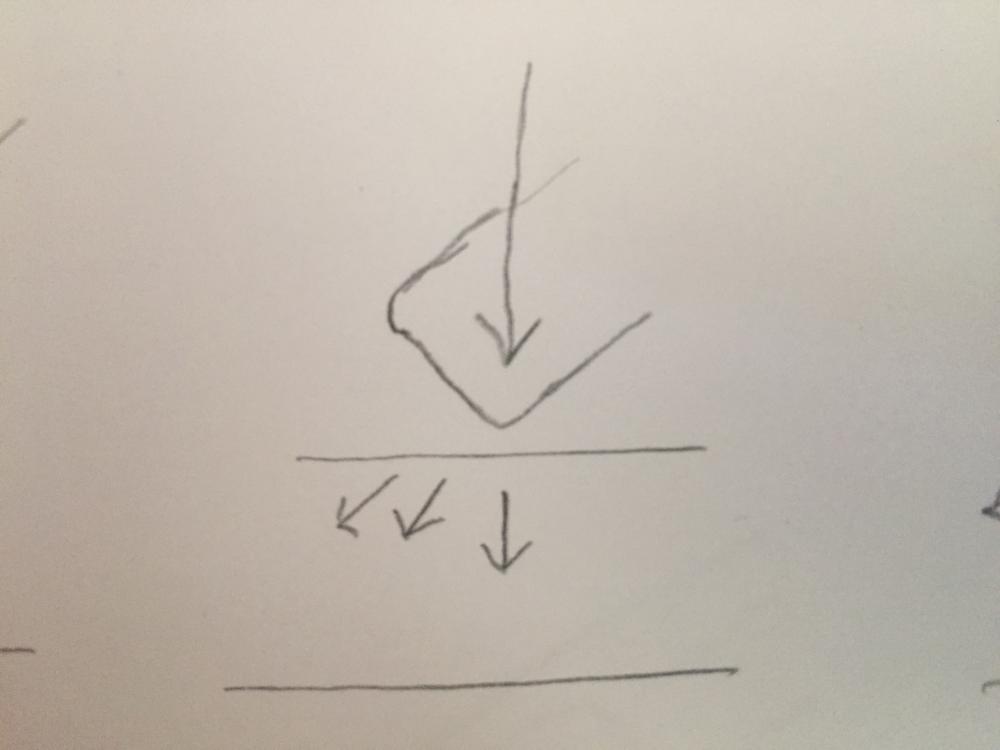

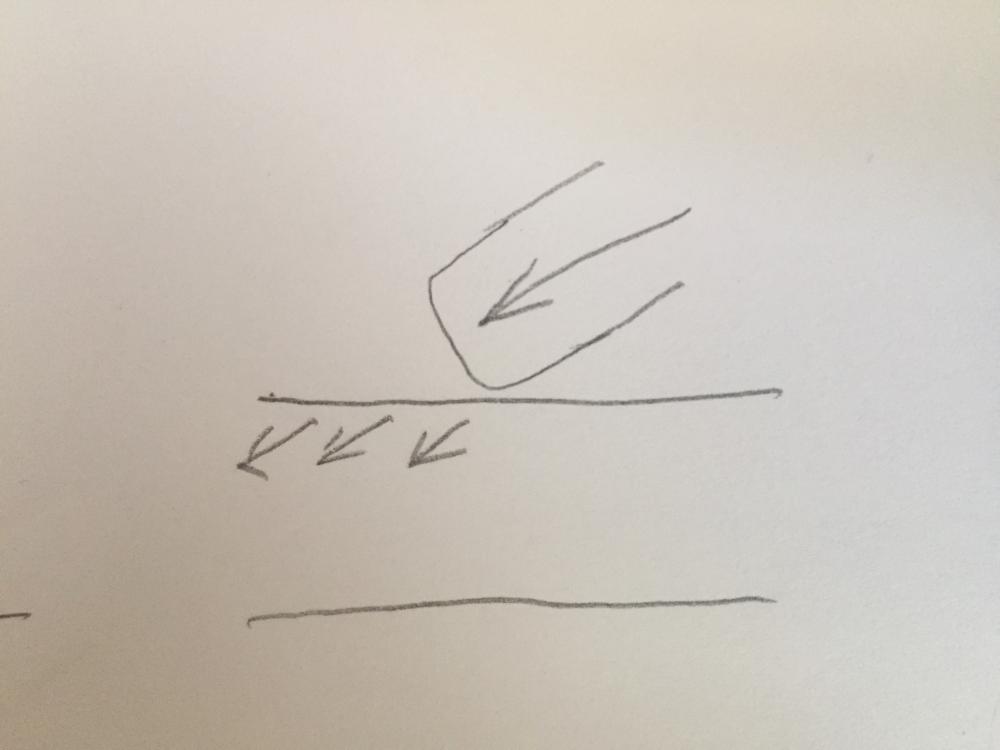

The following discussion began as comments on photos I posted about a new, rather slender rounding hammer I'd just finished. It seems to me that if we analyze this question, it really comes down to two important angles: the angle of the face of the hammer and the angle of the path of the hammer strike, both measured relative to the workpiece. For example, in the first these two drawings, the face of the hammer is parallel to the workpiece, but the path is different. Here, the hammer is angled, but the paths are again different. With each of these, the metal will generally move in the direction of the hammer blow, with the angle of the hammer face having a secondary effect on its flow. As far as precision goes, a longer, thinner hammer both will have a smaller striking area and will be easier to aim. However, unless the path of the hammer blow is precisely aligned with the long axis of the head, there will be more torque on the handle. In other words, the mass of the hammer head and the force of the blow will combine to form a lever with the impact point as the fulcrum. Whereas with a shorter, fatter hammer (like a farrier’s rounding hammer), the center of mass is going to be closer to the point of impact, creating a shorter lever with less torque. In sum, the longer, narrower hammer would theoretically be better for delivering at targeted blows at precise angles, so long as the path of the hammer head is in line with its long axis. The shorter, thicker hammer can strike along a variety of paths and would be more forgiving of hitting off-center or off-axis. Thoughts?

-

A creative solution to an interesting hardware problem at NASA

JHCC replied to JHCC's topic in Everything Else

I’m trying to get him to come join me in the forge if/when he comes to our next reunion (we were classmates at the college where I now work). -

A creative solution to an interesting hardware problem at NASA

JHCC replied to JHCC's topic in Everything Else

-

A creative solution to an interesting hardware problem at NASA

JHCC replied to JHCC's topic in Everything Else

The core of the detector package is an array of several miles of 3 micron copper wire wrapped around a square frame. Paul helped program the CNC machine that did the wrapping, since the wires had to be put in exactly the right places while keeping exactly the right tension (too little, and it would sag; too much, and it would snap). This is a long way of saying that whatever spec Paul made the washers to was surely exactly the right one! -

There are Plain Townships in Stark, Wood, Franklin, and Wayne Counties; which one are you in?

-

My friend Paul works at NASA, where he is part of a team building a highly sensitive instrument to measure the background radiation of the Big Bang (or something like that; it’s way over my head). He posted on Facebook yesterday with an interesting problem they faced and the solution that he came up with: ”We need non-magnetic conical spring lock washers to use at the connection between the thermal strap and the detector package. The detector readout circuit is one of the most sensitive magnetic field meters in existence, able to measure one 100 billionth of a single quantum of a magnetic field. (it’s a ratio measurement.) So I quickly made some conical spring lock washers out of spring temper phosphor bronze. As far as I know, these are not available from any vendor.” Cool, eh?

-

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

It’s a forging hammer; this is my current dishing hammer (made from a RR splice bolt, per a suggestion from ThomasPowers): I’m thinking of making another dishing hammer along the lines of the new forging hammer, but with much more dramatically domed faces. That’s still in the idea phase, though, not in the planning. -

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

Ash. There was a bit of a split in the blank that I thought I’d successfully worked around, but it opened up at the end. -

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

Thank you. It was inspired by memories of a hammer made by my teacher Fred Crist, combined with a desire for something with more precision and finesse than my other forging hammers. I’m looking forward to giving it a try. -

I like Ian’s suggestion, and would add to it that adding a wooden shroud around the spiral duct (similarly painted etc.) would mitigate its anachronistic appearance.

-

And that one was a real lemon.

-

Welcome to IFI! If you haven’t yet, please READ THIS FIRST!!! First of all, if you aren’t creating zinc fumes, you won’t need a mask for them. Keep anything galvanized away from your fire! Go read the JABOD threads in the Solid Fuel Forges section; lots of great info there for making an effective, low-cost forge.

-

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

Finished putting a handle on the new 2 lb. long rounding hammer: Unfortunately, the wood cracked as I was charring it. If this is/becomes a problem in use, I’ll put on another one. Annoying, but not really a big deal. Close-up of the head: 6” long x 1-1/16” at the thinnest. The faces are approximately 1-1/2” across and 1-1/4” high. -

First tries are always good for identifying things to improve.

-

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

Messed around with a bunch of bits and pieces of cold work, cleanup, and handle fitting, so I didn’t actually fire up the forge. However, I did need to heat up a yarn bowl for finishing and patination, so I popped it on one of the burners of the induction cooktop. Pleasantly surprised to see that it got the bottom up to a nice glowing red. -

When the tool rental guy in the big box store has bits for a Hilti jackhammer he no longer carries, you get them for a buck each.

-

Ah, the Victorian love of deifying British industry!

-

I like it, but the thinness of the loop is a bit out of proportion with the other limbs. Perhaps if you upset the top limb lengthwise before splitting the loop, that would give you some more thickness to play with.

-

And that’s where all the time spent researching Fisher’s production history really pays off.

- 658 replies

-

- Cast anvil

- Fisher & Norris

-

(and 1 more)

Tagged with:

-

Good call; cats don’t like getting passivated.