-

Posts

51 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by ironmutt

-

this what i went and got when i built mine https://www.menards.com/main/heating-cooling/gas-kerosene-heaters/garage-heater-replacement-parts/mr-heater-high-pressure-regulator-with-p-o-l/p-1444441194277.htm you could put a tee bewtween it and the hose to add a gauge if you realy wanted to

-

Ditto what Matto said . other advantage is the other side of the bench not popping up in the air when you give it a good beating

-

i under stand working only six inches at a time hence the mouse door plug to allow for heating in the middle with out heating up end that s still in the far end of forge with out stick out the end i would love to have a lay out table i could just go to town on with a torch but i dont have room for it right now . i have 2 anvils a forced air propane forge made from firebricks and refrac cement , 1/2 pipe side arm design with a pink 1960 hair dryer blower attached at the side and a turky fryer frame with a interior demention of 6''wide 6''deep and 4'' tall so right now if i want to do any thing larger then 6 inches i have to forge weld to gether every six inches or now mig weld it together, a quench bucket and a assorted stacks of scrap it sits inside cause it walks away on its own if i let it play in the yard, my recently aquired post vice and stand i built and a mig welder all cramed in to a 8ft x 11ft area i still have to walk throu to get in and out of my house witch is also why i want only one opening on the forge so i only have to keep a close eye on the front since the longest piece i plan to do is 36'' i figure 24 deep should allow for doing one end up to the middle then quenching doing other end same way

-

no its not i got a buddy that 6'7'' his wrist are even to his waist just like me but his waist is alot higher then mine for sure eevery person is diff . i am 5'11'' but have a 30'' inseam my brothers inseam is 32 and he is same hight as me (only know cause i payed for the suits for my wedding and they kept mixing up our pants at the store when they fitted them) so its best to set your work area to you then every one else can pound sand if dont like how high you got stuff by the way a rule of thumb is to set it up knuckle high but not a law so if you like it a little higher or lower doit cause its your area

-

i am wanting to do longer stock like pickets and twisted ballisters but because of logistics i need the back of the forge closed for right now i figured with central located burner located in the middle of the side angled up to the curve to cause swirl it would heat over all better but still have a hot spot in the middle i was considering build it with a fire brick cut to inside demsions with a mouse hole like off tom and jerry to block off most of the back of the forge as needed but still let me poke a peice all the way in i can move it forward and back as needed with the end closed off with plate and layer of wool i have some 24in long hard shelf for the floor i can cut down to 3 in wide to put on the bottom

-

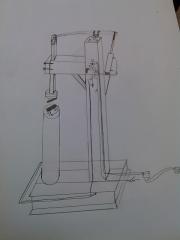

i finished this up today need to runnint thru the car wash then hit it with some rustolem with out being bolted down it dont move i left the tool rings lower so i can use the top for setting work on when i need to reposition or to set hammer on while clamping it down after buying a cord end for the welder i scored for free and running to the scrap yard i got right at 100 bucks invested with the vice

-

ok so as title says math help i have a 8.75 outside diam. pipe .25 wall thickness so 8.25 inside 24 inches long if i put 2inches of kaowool it should come out to 320 Cubic inches so a single t burn should work or i was considering a 2inc wide 12 inch ling ribbon burn to spread the heat around am i on track math wise or am i off my rocker

-

control circuit for pneumatic hammer

ironmutt replied to ironmutt's topic in Power Hammers, Treadle Hammers, Olivers

thank you i was able to actual search for that one you wouldnt happen to haqve a pic of the rest of you controls -

control circuit for pneumatic hammer

ironmutt replied to ironmutt's topic in Power Hammers, Treadle Hammers, Olivers

ok i get ya so a air controllered 5/2 then a 3 way tied to on offs at top and bottom of ram throw but i am con fused as to what controls the bpm on an air system only .control do you ball valve the exhaust at the 3 way or at the 5 way valve i have looked thruh 6 pages of threads used the search funtion , google and youtube no budy does a complete walk thru of like air in here to this valve this vallve connect this port to this port on this valve back to these swithces . there is a pnumatic can crusher that is automatic that that looks like it could be scaled up and ad control on the exhaust side on you tube but even he doesn't explain the skematic and most of the parts numbers people are listing as what they used when i search them come up with bubkis worst part is they say i used this valve a xxx890239029 what ever instead of i used a 5/3 piloted sorry for the rant i have been tring to design this thing for a while now and am down to the controls i dont like spending money in the blind i have managed to source every thing but the cyclinder and controls . i am slowly going insane on this one. ps thanks for the help JWS -

control circuit for pneumatic hammer

ironmutt replied to ironmutt's topic in Power Hammers, Treadle Hammers, Olivers

i drew up a quick scetch of my idea with the weight distributing bars in the middle of the second pic only reson ask about them is i have 5 sets sitting in my shed right now i am looking at about 60 pounds for the top die and verticle bar my under standing on the 5/2 solinode is that when paower is supplied one port is charged with air and the other is oped to exhaust when power is taken away they swap places so by alternating with a flasher it will open and close with out the extra switches and links rune ehaust thru a ball valve linked to foot peddle -

-

control circuit for pneumatic hammer

ironmutt replied to ironmutt's topic in Power Hammers, Treadle Hammers, Olivers

ok s 52 views and no answers then let me pose another question the spring on a kinyon style has any one used sway bar s from a rease set up was thinking put the narrow end over the hammer side so that as it piviots that side will get mor whip out of it but with a shorter depth over all a world wide forum and you have decided 11 hours is too long to wait ? hmmmmm. -

my idea is to run a 5/2 solenode like this http://www.ebay.com/itm/1-2-DC-12V-5-way-2-position-Pneumatic-Electric-Solenoid-Valve-NPT-Air-Aluminum-/281360345142?hash=item4182622836:g:Mp4AAOSwhh5Tmlqn then wire it to a flasher unit like this http://www.ebay.com/itm/2-Prong-Electronic-LED-Compatible-EF32SS-Solid-State-Turn-Signal-Flasher-25-Amp-/400665610452?hash=item5d498808d4:g:SuUAAOSw~gRV6Kss&vxp=mtr with a ball valve on the exhasut port linked to a foot peddle will it work is what i am wondering i know i cand do the electric all easy but not sure if an electric controlled 5 way will fill and empty fast enough to hammer with

-

i am about build a propane froge first one . my question is can i use the regulator off of a acetaline bottle set up or do i have to have the adustable one from a propane supply house i. i can get a regulator from harbor frieght for 35 and a hose for 15

-

thank you if you ever get to galesburg ill or i am up there the beer is on me

-

not sure how to post pics in a forum but did put four ok ones up in the anvil gallery of my new to me arm and hammer 172 pounder serial number 15263 i got it for $175 i felt guilty almost dirty buying it for that price . but i wasnt gong to walk away from it either ps anybody that has richard postmans book want too look up the number for me i would owe ya a beer/pint if we ever meet

-

Arm and hammer anvil

ironmutt replied to Rhettbarnhart's topic in Anvils, Swage Blocks, and Mandrels

hey my arm and hammer is #15263 any idea on the date it wieghs 172# on the scale i got it for a dollar a pound