eseemann

Members-

Posts

967 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by eseemann

-

So these torches are shown on 1 pound bottles. I love using the adapter for a 20 pound tank with these small torches. I tend to agree with Mikey98118, they automate as much as they can with these ads. I think there is a max BTU/hour you are going to safely get out of a 1 pound bottle and I am guessing it tops out under 10,000 BTU/hour

-

So according to the Amazon page for this "Double Flame Jet Turbo Torch Head High Output 17060 BTU+propane MAPP MAP Pro Handheld Torch", Amazon number B0BQLMKFR3 either is someone just using ChatGPT to make a random description OR this is from Krypton. DOUBLE FLAMES: Powerful Double Turbo Flame, heat up to 2372°F (1300°C).High output of 17,060 BTU/hr, consumption rate is 367.6 g/hr (5.0 KW), powerful enough to weld large diameter copper pipes. 17K BTU assumes that it is about 8.5K BTU per pipe. That is more than a Bernzomatic TS8000 from a one pound propane can. I have to wonder if you can safely get that much gas out of a one pound can using hand held torch. 1 Litre of propane = 7.08 kWh (kilowatt hours) or 24000 BTU/h. 1kg of propane = 14.019 kWh (kilowatt hours) or 47300 BTU/h. 1 Gallon of Propane = 27 kWh (Kilowatt Hours) or 91,452 BTU/h

-

So Harbor Freight says they have a "cast steel" anvil now.

eseemann replied to eseemann's topic in Anvil Reviews by brand

I think that is a good idea having a smaller anvil that you can talk on the road. From what I remember from what I have read a number of anvil brands were cast iron with a steel face. Here is another review https://www.youtube.com/watch?v=DtnXz5Jzirg -

So Harbor Freight says they have a "cast steel" anvil now.

eseemann replied to eseemann's topic in Anvil Reviews by brand

So the beat the thing like it owed them money and missed a payment. It looked and sounded like an improvement over the cast iron ASO. Like this one that included some type of gap filler found when cut in half. -

So Harbor Freight says they have a "cast steel" anvil now.

eseemann replied to eseemann's topic in Anvil Reviews by brand

They might have a good starter anvil (or anvil like object) for people that cannot find anything else. Thanks for the info. -

Good Morning All, I remember some time ago there were posts about HF cast steel anvils (Russian made I think) but by that time I only saw the cast iron ASOs at HF. I wonder if anyone has seen one in the store. I will be going by HF this weekend to see if they have one in stock. Not so much that I want one just want to see what it looks like. The DOYLE™ 65 lb. Cast Steel Anvil is constructed from premium cast steel for high hardness, strength, and durability while providing up to 80% rebound. The 50 sq. in. face provides ample surface area for shaping heated metal. 3/4 in. hardy hole 3/4 in. pritchel hole 7.1 in. x 3.7 in. horn 80% rebound Made the Kessel Run in less than 12 parsecs.

-

I still need to work up to coating a forge. I have ended enough soft fire brick in my time, really need to get on the stick

-

Yup, that sounds about right for what the manufacture would say. That about as helpful as the old joke. Doctor, it hurts every time I raise my arm over my head, what do I do. Doctor: Stop raising your arm over your head.

-

This is why I think twice about used compressors

-

Daswulf, you are 100% correct. Like the anvil stones used in past times that would only last until the stone has had enough of this getting hit with a hammer foolishness.

-

I’ve had enough of a bick in the thigh

eseemann replied to Machine shop's topic in Repairing and Modification to Anvils

I love how the Lady and the Tramp trope shows up everywhere. -

I had worried that the counter weights would be cast iron. Is that cast iron or steel?

-

I have seen several people say you can forge steel on an oak other hardwood stump if the steel is hot enough. I have a striker plate made from a road scraper blade that I think is ar500.

-

And I am always amazed at how steel can be recycled over and over again. In many cases in to soup cans, the pot to heat the soup, the burner eye and stove to cook the soup and the spoon to eat the soup.

-

You got me, this is a prototype.

-

Kelvis, Have you ever worked with hydraulic gear before? I just built my press using an air over hydraulic jack. That is a good way to start if you have not done much with hydraulic plumbing.

-

Robert, if I could find a hat to fit my over sized head I would tip it to you. I did a bit of looking but did not have time to come up with anything useful. Well done.

-

Aframe, what I would ask is what is the hand pump max PSI, what is the ram rated to and it would be REALLY nice to know the flow rate of the hand pump. You can (I think) figure this out with the Piston / Bore Diameter, Rod Diameter and speed of the Stroke. This also requires (again I think) you know the Pressure. That will give you a starting point. Do you have the make and model number?

-

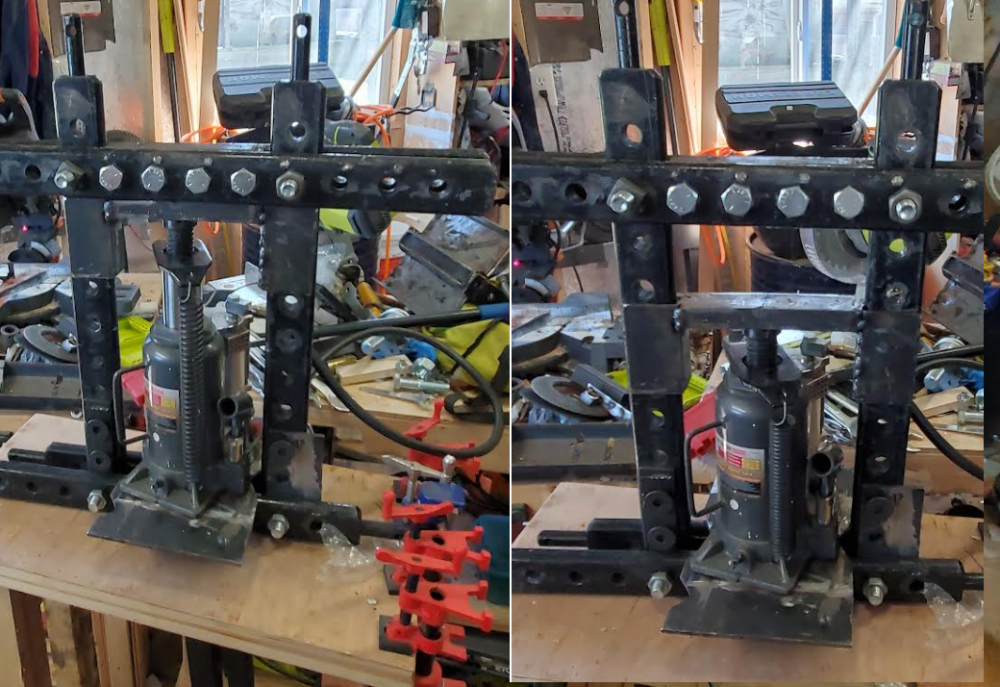

FYI, My workshop is a total mess right now. There was no tornado or anything, it would better after that. So the biggest problem I have been having with a press is making my rails line up and my welds holding. I had an idea to try using CAT 1 drawbars since they are already drilled. I got a crazy good deal on some for around $19.00 each and shipping was $30.00 for all 6 of them. The bolts are CAT 5 3/4 inch bolts. I like this idea since I can change the configuration as needed. The angle iron I squished is about 3/8" thick. The angle iron was cold when I smashed it. I was out of the line of fire if it shattered and I had a full face mask. Also check out this ginormous pin I got at the scrap yard a while back, I am thinking rail car, what do you think?

-

Good Morning my good folks, My brother in law, Mark, is located in Tuscon AZ and needs to find a shop that will sell him a section of 5 inch OD +/- square tube. He needs good and thick section of tube for the bike rack on his travel trailer. The tube that came with the trailer was so thin the bike rack caused it to bend. Does anyone know of a cut shop that will sell less than a full 20 section of steel? Mark is about to go on to training to be the captain of the DC-10 tanker he works called "Big Jucy". Big Juicy is a fire fighting tanker that works fires in the western US. I would like to take this off his plate since he is moving back in to fire season. If you, or your inner 12 year old, want to see the DC-10 search for "Friends Who Like " Big Juicy ". My Mother in Law and Father in Law are in Chandler AZ so I think Mark could take the drive to Maricopa County if someone had a good lead on some square stock. The person working on his trailer said they needed 4 inch inner diameter and my sister in law wanted it to be strong so I am thinking 4 inch ID with .25 inch wall would outlast the rest of the trailer. I don't know how long they need but I would assume at least 4 feet and no longer than 8 foot. Mark is a good dude and he is about to go in to his 200 day work week fighting fires so if anyone knows of a cut shop in Tuscon or Phoenix please let me know. Thanks Ernest

-

Once the magic blue smoke leaves the motor it is a doorstop.

-

I just saw this. It looks like what would result when Hephaestus looks at Zeus and says "hold my beer". That is amazing

-

Tire hammer on Dirt floor?

eseemann replied to Scratch's topic in Power Hammers, Treadle Hammers, Olivers

Yup, I would not try that on a plywood floor either. Thanks -

Tire hammer on Dirt floor?

eseemann replied to Scratch's topic in Power Hammers, Treadle Hammers, Olivers

I have a plywood floor in my shop, galvanized steel joists 12 inch on center, and I did not think that would work for any type of power hammer. I was looking at the little anvil mounted power hammer plans from Christ Centered Iron Works. The guy at Tuff Shed said I could park a car on this floor but I have to think that a 2,500+ car across 4 tires is much less stress than a power hammer across 16 square feet.