-

Posts

98 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by navasky

-

Does anyone have any recommendations on where to get a custom touch mark that won't break the bank? I'm looking for something that can be used for both hot and cold stamping. I see a lot of cheap ones on Esty but they look like walls of the design go straight down instead of being angled like a normal metal stamp which makes me question their durability.

-

Do a google search for "sayber osg"

-

4130 or 4140 are good guesses for sawblades with cemented teeth or abrasive grit.

-

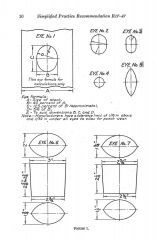

US Dept of Commerce Forged Tools Recommendation

navasky commented on rthibeau's gallery image in Members Gallery

-

Masonary Diamond cup wheel for grinding blades

navasky replied to BeaverNZ's topic in Grinders, Sanders, etc

Diamond doesn't work well on steel, cbn is what you would want if you decide to go ahead with it. -

Greece and Galia....spears...

navasky replied to Ibor's topic in Spears, Arrows, Pole arms, Mace/hammer etc.

Those came out great. How did you do the rib? -

Rail anchor properties

navasky replied to BackwoodsBeast's topic in Blacksmithing, General Discussion

Looks pretty close to 9260. I like to use them for tomahawks. -

What did you do in the shop today?

navasky replied to Mark Ling's topic in Blacksmithing, General Discussion

Pretty, and according to wikipedia bronze is harder than wrought iron, so the rebound should be good too. -

What did you do in the shop today?

navasky replied to Mark Ling's topic in Blacksmithing, General Discussion

Ever thought about trying to cast one of those bronze anvils over a steel faceplate? It's something I've always wondered about, and a 6 pound one would make a nice little jewler's anvil. -

The machine shop at work was getting rid of this. 130 lb Vulcan with a perfect face except for a couple of spots where some idiot torched it. I remember back in 2012 when I was desperately searching for my first anvil, I never would have thought that people would be giving them away to me for free just a few years later.

-

Tool Handles. Yeah, I know, hickory is king, but...?

navasky replied to Leland Stone's topic in Tools, general discussion

I made a handle from bamboo flooring once, it's held up fine so far but isn't the most beautiful wood and I ended up finding some small voids in the material. Some day I'd like to actually split and laminate some bamboo by hand. -

Tool Handles. Yeah, I know, hickory is king, but...?

navasky replied to Leland Stone's topic in Tools, general discussion

I found the source of the chart with a reverse image search, http://www.aikiweb.com/weapons/goedkoop1.html. It looks like he's hitting the wood with directly with another piece of wood, which is not exactly analogous to the type of stress it would see when used as a tool handle. -

I've achieved a good blued mirror finish with "slow" rust bluing. I use Mark Lee express blue but my understanding is that most of those instant plum browns followed by boiling will give you the same effect.

-

That looks fantastic. I've been wanting to make a vise from forklift tines forever. Just out of curiosity have you thought of putting the screw on the outside a la the vertical vise? It would save having to drill those 2 big holes and you would be able to grip longer pieces.

-

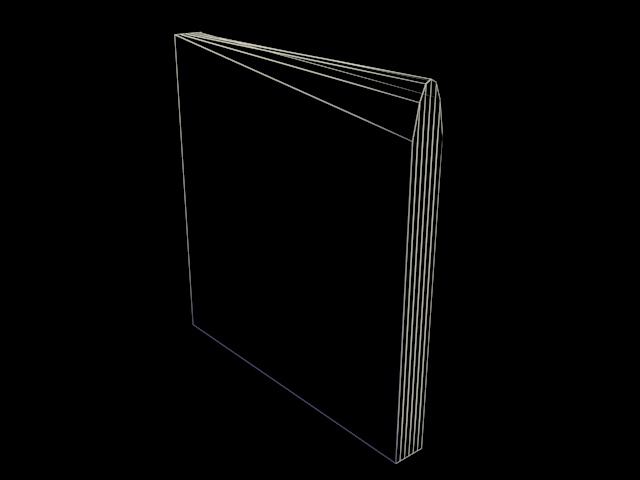

I got this 2" x 20" x 20" block a while ago and just finished up a stand for it tonight. Made from scrap wood and old bed frame angle iron. The next step is to put some different radiuses into one of the edges so I can stand it up and use it as a die anvil. Eventually I'd like to make a few different sized holes through the face for drifting and some shapes in the other edges too. I guess I need to invest in an angle grinder now...

-

Thanks for the info Foundryman, I appreciate it. It sounds like the harder the metal the more treble you end up with.

-

Don't know if it would wear the strings faster, but if your requirements are for something thin and springy why not use steel? You could even electroplate it with copper to get the look.

-

Looks good, I like that petal texturing.

-

Cool job! My understanding is that bell bronze can be hot forged and also cold forged to some extent but needs to be annealed frequently. Just out of curiosity do you have any experience with the acoustic properties of other metals? I know that cymbals are usually made from bell bronze but can also be brass and sometimes even nickel silver. I wonder what the differences in the sound are between the different metals and what physically is making them sound the way they do.

-

I've seen that one but there are others of them forging the bowl from a thick round ingot. There's a lot of contradictory information out there but I believe the cast ones are brass and the forged ones are bell bronze and considered superior. This page has some info if you're interested.