-

Posts

17,325 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Glenn

-

-

The metal chair is not an ideal working platform. Find a comfortable chair with back support and then tilt the anvil, work station, to match your supported and comfortable position. Adjust the anvil, work station, height to your arm position.

-

The bamboo can be used in many ways, including tomato or plant stakes, wind chimes, bundle them together and offer them for sale at the farmers market, or use them as fuel for a solid fuel forge.

-

Get a color chart of the color temperatures and compare to what you see on the chart.

-

First tic of the season today. Was not attached yet, but was looking for a place to bite and have a meal.

-

Bedding the anvil down in sand kills the ring and the anvil height is still adjustable.

-

Hofi has passed away. You may be able to contact Hofi Blacksmith Workshop | Kibbutz Ein Shemer Israel and ask if they are available there. Angele was Hofi's world wide distributor and lists the Hofi hammers on their website.

Hofi grip and swing of his hammer made a 3 pound hammer feel very similar to a regular 2 pound hammer, but with half again the mass.

Scroill down to the text

BP1002 Hofi Hammer Technique - The Swing

BP1000b The REAL story about the Hofi Hammer

-

Put that in some 150*F water so it melts and then stir. Makes a nice paste that way.

-

49 minutes ago, Frosty said:

Virtually everybody has a telephone and phone book.

I have not seen a paper copy of a phone book for many years. Would not know where to go to even find one as they took out all the pay phones and phone booths. Land lines are useless without some type phone book or directory. Calling the operator to ask for assistance is a thing of the past.

A cell phone and a google search will locate some phone numbers, but that means you go on line. You then have to save the number to your cell phone or look it up again later if you need it. That saved number does not include "press 1 for one thing", "press 2 for something else", and even then does not list the specific department you want, etc, or getting the person that has the information you need. We will transfer you, and they are most likely away from their desk or busy with another customer, so talk to the recording. If you do find a knowledgeable individual, they do not have a direct number or extension, so you get to start from the beginning.

Phones are no longer attached to the wall with a 3 foot cord. Forget about the party line shared by multiple households, and you can tell if the call is for you by the long and short combination of rings.

Try telling someone you do not have an email address, just send the information in a letter.

-

There are pintle tow rings threads on the site. They may give you some ideas.

-

Put a list of credits, contributors, and links under show more in the description of the show. If folks are interested, they will look them up.

-

Keeping the advertising of products and sponsorship to a minimum would be preferred so the program does not look like infomercials. Commercial stickers plastered everywhere are distracting, and takes away from the content and continuity of the show. We chose to watch the program, not to see on who paid the most to have their company or product name thrown in your face.

-

The canister here contains a BLO and beeswax mix. Remove the lid and the canister is large enough to drag a rag into the mix and transfer to the metal.

Suggest you coat the outside of the canister as they tend to rust quickly.

-

Be careful with the heat. Next 10 days here are 87*F (30.5*C) or above. And summer just started.

There are several threads on the site as how to deal with the heat.

And do not forget the animals as they need relief from the heat also.

-

Old Lincoln welders can be repaired. Try to replace the circuit boards on a new welder, if they are even available.

-

If you do add a brace, make the height of the brace so a shoe can fit under the brace.

-

A drawing or list of the features you want in your anvil would depend on what you want to be able to do with the anvil. One horn vs a double horn, one or multiple hardie holes, step between the horn and face, an upsetting 5th foot, mounting holes in the feet, turning cams on the side or the back of the anvil, square clip horn, round clip horn, thick or thin heel, thick or thin waist, etc. Once you have a drawing, please post it so we can comment further. And there is nothing that says you can have only one anvil

Consider the steels available and their properties, choosing what fits your project. It may be to your advantage to have the anvil cast.

-

Gather together all the hooks and coat them with BLO. It keeps them from rusting.

-

Thomas Powers Demo on Twisting NMABA Meeting April 2, 2022

-

Direct from a newly discovered wall of the Lascaux Cave drawings. They managed to get proof that the Curmudgeons have been around a lot longer than ever thought before.

The original IFI curmudgeons t-shirt from September 23, 2016

-

Condolences to his family, friends and those that knew him.

-

Claims.

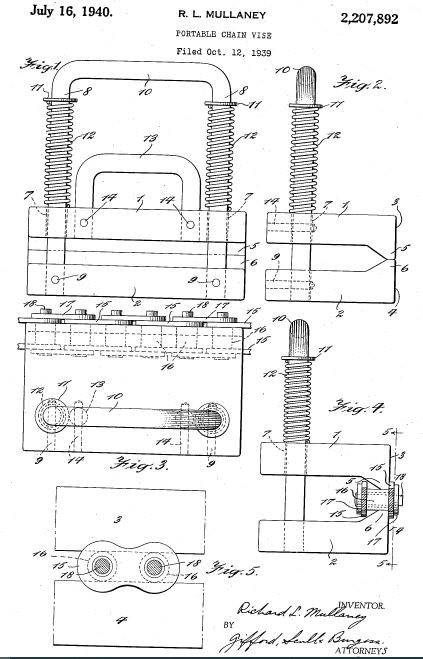

This invention relates to a novel and improved form of portable chain vise, the novel features of which will be best understood from the following description and the annexed drawing, in which I y have shown a selected embodiment oftheinvention and in which:

Fig. 1 is a longitudinal elevation of the selected embodiment as viewed from the left of Fig. 2;

Fig. 2 is a vertical elevation of the vise as viewed from the right of Fig. l;

Fig. 3 is a plan view of the vise showing a section of chain in place;

Fig. 4` is a view similar to Fig. 2 but showing a section of chain in place in the vise;

Fig. 5 is a view on the line 5-5 of Fig. 4.

The vise described and claimed herein is designed for use in making repairs or `replacements of parts of chains, more particularly roller chains. For example, in a truck employing a roller chain drive it oftentimes happens that the chain must be repaired by replacing parts thereof and one of the rst things that must be done is to remove the pins which connect the parts which are to be removed. It is the object of this invention to provide a vise which is portable and which may 'be used to hold. a roller chain of any size in such a position that the pins may be easily removed. Those pins are oftentimes riveted at both ends or have driving its in the holes of the side plates of the chain and to remove them a firm support or anvil must be provided which will firmly en.

gage the side plates while' the pins are being vdriven out of the chain. With the vises now in use it oftentimes happens that the hammering on the pins will actually bend the side plates or other parts of the chain and damage them enough so as to require replacement. These and other disadvantages are overcome by the vise now vto be described.

For the purpose of illustration, I have shown the vise as comprising two plates I and 2 which are preferably of the massive construction shown so as to provide a relatively heavy anvil and to withstand the rough-usage to which the vise is subjected. The plates have edges 3 and I which are in the same plane, and at those edges the plates are provided with relatively narrow jaws 5 and 5 which extend toward each other and which when in contact, as best shown in Fig. 2, will hold the major portions of the plates apart.

The one plate I is provided with a pair of holes 'I through which extend the parallel legs 8 of a U-shaped rod. The ends of the legs 8 are anchored in the other plate 2 as by pins 9, and the bottom of the U indicated at I may conveniently be used as a handle to carry the vise from place to place.

Adjacent the upper end of each leg there is secured an abutment II, between which and the top surface of the plate I is disposed a compression spring I2. These springs are under compression so as to yieldingly force the jaws and 6 together.

Anchored in the plate I is a grip I3, which for convenience may likewise be made of a U-shaped rod having its legs anchored in holes in the top plate 'by pins I4.

In operation, when it is desired to use the vise, the operator may raise the plate I against the action of the springs I2 by taking hold of the grip I3 and pressing it upwardly towards the handle I0. that if the palm of the hand is rested on top of the handle I0, then the fingers of the hand may conveniently take hold of the grip I3 and raise the top plate which will slide upwardly on the guides formed by the two legs 8. The plate I is lifted far enough so that the jaws may be vput in place over the part of the chain which is to be repaired, as shown in Figs. 3 and 4. The edges 3 and 4 of the plates I and 2, being in the same The parts I0 and I3 are so spacedv gage the side plates I5 of the chain. As is well known in the chain art, a roller chain is usually formed of a succession of blocks, each block being formedV of two of the plates I5 and associated rollers I6 usually mounted on bushings which connect together a pair of plates I5. A series of blocks are fastened together by outside plates I'I which overlap the plates I5 and then the blocks and plates are pivoted together by pins I3 which pass through aligned openings in the overlapping plates I5 and I'I. These pins are fastened in place in the chain by various means (not shown), but usually they have a tight fit in the outer plates I'I and in fact sometimes are riveted or upset to hold them in place.

When a length of chain is engaged by the jaws, as shown in Figs. 3 and 4, the plates I5 may engage the anvil faces formed by the edges 3 and 4 and then the pins I8 may be driven out of the chain by a hammer. oftentimes the force necessary to be applied to the pins is so great that with 1 not in contact with either of the anvil surfaces adjacent the center of the plate, but in any event such plate is always uniformly supported at at least four places, that is to say, the places adjacent the pins I8, where the greatest impact occurs, so that when one of those pins is hammered out of the chain, the chances of the plate l 5 being bent by that hammering are reduced to a minimum.

While I have shown the invention as embodied in a specific form, it is to be understood that various changes in details may be made without departing from the scope of the invention as defined by the appended claims.

l. A portab-le chain vise comprising two massive plates disposed generally parallel to each other, a U-shaped rod having parallel legs loosely extending through holes in one plate and anchored at their ends in the other plate, one or more springs arranged to urge said plates towards each other, and a grip on said one plate on the side opposite said other plate, whereby said grip and the 'bottom of said U may be grasped in the hand to overcome the effect of said springs and move said plates apart, said plates having narrow jaws adjacent one edge contacting with each other under the action of said springs, and said plates inwardly of the jaws being spaced apart.

2. A portable chain vise comprising two massive plates disposed generally parallel to each other, said plates having edges substantially in the same plane, narrow jaws on said plates at said edges and extending towards each other and adapted to engage each other to hold the rest of the plates apart, a handle having parallel legs loosely passing through holes in one plate and anchored' and extending towards each other and 'adapted to engage each other to hold the rest of the plates apart, a guide slidably engaging one plate and secured to the other plate, spring means urging said jaws together, and means engageable by the hand to pull the jaws apart against the action of said spring means.

RICHARD L. MULLANEY. l -

I am glad you have avoided illness. Not everyone is so fortunate. Look up heavy metal positioning, fume fever, and etc. and galvanized, zinc, fumes, and milk. Welders are routinely exposed to the substances that cause metal fume fever from the base metal, plating, or filler. The most common form of exposure among welders occurs when welding galvanized steel, of which zinc is the primary component of the galvanization process. Ref: Wiki

Zinc is airborne and goes into the lungs. Milk is a liquid and goes into the stomach. The two are completely separate systems.

You may want to look up Jim "PawPaw" Wilson, a blacksmith who got into zinc fumes in his shop. The zinc did not kill him but opened the door for pneumonia and other problems and sent him to the hospital. A very short time later he died.

IForgeIron is all about safety, in over 150 world wide countries that visit the site. They may not know the cautions of zinc and other heavy metals, but we can bring it to their attention.

-

A visitor to my shop and he noticed my Vulcan had the horn pointed to the right, when he turned around he saw the Hay Budden that the horn was pointed to the left. He asked why the Hay Budden horn was facing left. Simple I told him it's a left handed anvil. Irondragon

-

A round punch, a pritchel punch, and some bar stock, so what is the problem? When finished, they don't even have to fit a horse?

Anyone forging button hooks?

in Blacksmithing, General Discussion

Posted

Consider taking 4 pieces of square bar, welding the ends, then heating and doing the twist. The 4 lines go all the way through and form an open twist, with nice sharp edges