lary

Members-

Posts

259 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by lary

-

-

Thanks every one for the congrats. I'm honored. Brady wasted no time getting it in the mail. Received the tongs and a generous amount of gifts an hour ago. It's so cool to put my hands on somebody else's work. The tongs are great, I'll be trying them tomorrow.

-

Nice work! I'm betting that will be your most used hammer for a while. Since I started using a 2 lbs. hammer I hardly touch anything heavier.

-

Nice attention to detail. Thanks for sharing.

-

Brand new here (and to the craft), just begun building a JABOD

lary replied to TommyVee's topic in JABOD - Just A Box Of Dirt

Yep, I don't understand why people make video's with music blaring away while talking. Or they tell you how hot Georgia is in August 3 years ago when they made the video. -

Jeez Steel Horse, that's quite a story I'm glad your around to tell it. Tried to sign up with my first name, wouldn't let me so I dropped an r.

-

Thank you Frazer. I'm looking forward to more participation on this thread. Maybe I should call it non-traditional methods. Still struggling to understand the lines drawn between traditional and everything else.

-

Congratulations, 8 years to go for me. I have never regretted changing jobs or careers, but usually been a little nervous at the prospect.

-

There's got a be a way to make them into improvised anvils.

-

What did you do in the shop today?

lary replied to Mark Ling's topic in Blacksmithing, General Discussion

That's some pretty cool camo. I didn't even see the frog at first. -

Thanks guys. And yes I resorted to unconventional methods again with a mig welder. Welded at 3 points, sanded them down a bit to avoid any sharp edges.

-

-

Blacksmith Basket twist poker challenge... Video

lary replied to jlpservicesinc's topic in Blacksmithing, General Discussion

Thank you Jennifer for the challenge. It was an enlightening experience. I've been able to get scrap pieces to stick together, but when it comes to making something for real my forge welding needs some work. -

Blacksmith Basket twist poker challenge... Video

lary replied to jlpservicesinc's topic in Blacksmithing, General Discussion

I lost track of time on this (meaning it took hours). I switched over to gas forging to have better control. But I still can't get it hot enough to forge weld. Sorry no video. -

Blacksmith Basket twist poker challenge... Video

lary replied to jlpservicesinc's topic in Blacksmithing, General Discussion

What I started with, 3/8 and 1/4 inch round, Folded the 1/4 inch in half and slid them together, Attempted to forge weld with charcoal and failed. At this point I managed to get the tip of the poker forge welded but kept struggling with the basket. So I mig welded the basket together, then mig welded that to the 3/8 shaft. -

Might need a fire barnyard animals thread, chicken and a donkey so far.

-

Hmm, maybe being the straight man is something I could be good at. Mr. Powers Your exposing my greenhorn's when it comes to blacksmithing tools. I didn't give it a thought when I started the salvage process it could be a bunch of parts thrown together. It had a coating of oil,dirt & rust that was so even the fix had been done decades ago, after the 250 pound shop gorilla/apprentice bounced up an down on the handle. Everything was seized, I had to stick it in a press to get the screw box out. Anyway, it's working much better now.

-

Biggun, wish there was some magic I could offer you. Something in the shop/garage is waiting for you to create. Twisted. Think I might have a sister to your vise. No marking except the 35. I have no reason to believe the screw box is not original.

-

Thanks guys for the comments! Thank you Randy for posting those pictures. This place is great resource.

-

In Oregon it seems blacksmithing tools run on the high priced side. Seller wants $250. I'm not in a hurry to get one, but would like to be set up better than I am for coal or charcoal. 'Thanks for the input.

-

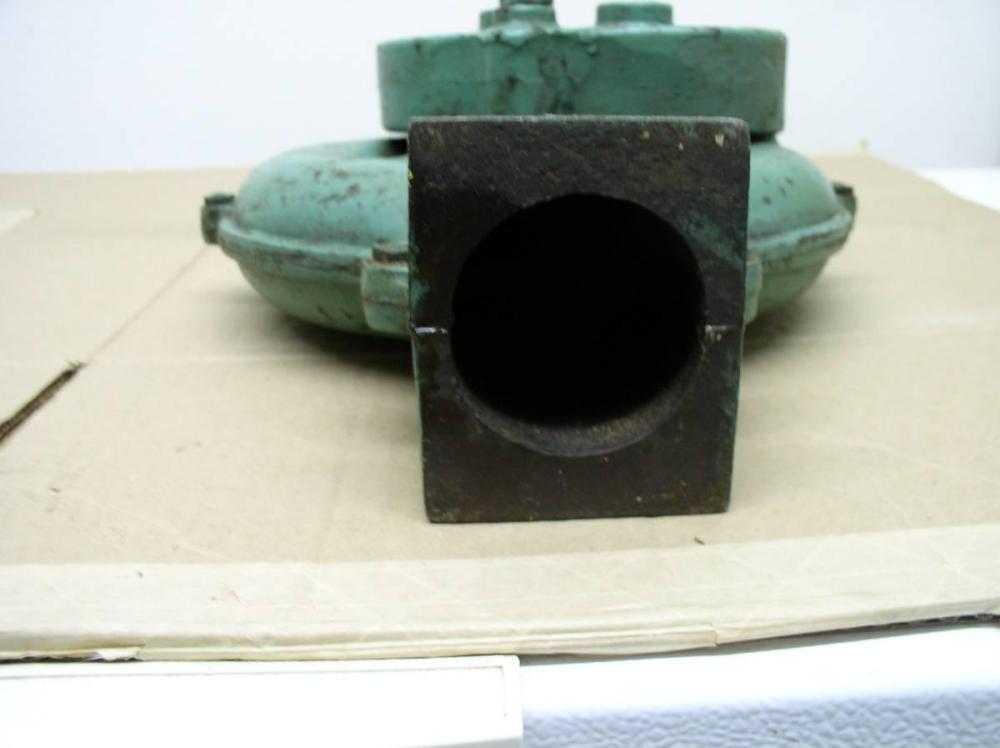

I haven't talked to the seller yet, but how is this mounted / secured. I'm guessing it mounts to the forge at the square flange? I don't see a way to put this on a stand. Or is this a cival defence blower?

-

-

Check with Glenn, I've purchased Plistex from him.

-

Rick, Got any pictures from the side? i was trying to figure out how the piece that is the hammer is guided. I built mine from scratch without plans so I get a kick out of seeing others. So it looks like the idler is the base? That mite help to make it more stable with all that weight down low, most I've seen use a 1/2 inch plate.