-

Posts

212 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by picker77

-

Soliciting sanity check before I light this new forge

picker77 replied to picker77's topic in Gas Forges

If it's doors I need, it's doors I shall have. Unfortunately I don't have any Plistex or Matrikote, all I've got is some kiln wash and a few pounds of Kast-O-Lite LI 3000. -

Soliciting sanity check before I light this new forge

picker77 replied to picker77's topic in Gas Forges

Thanks for the concern, Steve, and I certainly acknowledge the inherent dangers if I planned to routinely operate as it is. However, as I said in my initial opening post on this topic, "This forge will be operated almost exclusively outside". It so happens I'm waiting on delivery (today, in fact) of a 12 ft regulator/hose setup which will allow leaving the tank always outside, no matter where the forge is. This little exercise this morning was simply to do do an initial light off, and to gain any further comments from experienced members on the reworked plumbing. This will probably be the only time it ever gets operated with the tank installed in the cart, although even in this instance it was sitting in the middle of a wide open garage door, and was 3' from another open door. I could and maybe should have done the testing by wheeling the cart outside, but I was concerned about being able to properly see the burner flame and other heat colors in very bright summer sunlight. That's good news, Buzzkill, I'll use the bricks I have for heat doors, didn't like the idea of messing with soft bricks anyway, lol. Thanks. And roger all on the rifle, pistol, and black powder comments. I have reloaded off and on since the 60's, and I'm pretty careful with propellant and primer storage. In fact, like most, I don't use black powder any more because of the cleanup hassles and handling/storage risks. There are now excellent and safe modern substitutes available. I'll leave the black powder to the pyrotechnics guys, handling the stuff always scared me anyway, because of static electricity. Getting zapped by a doorknob in winter is one thing, drawing a static arc from your loading press is an entirely different thing! -

Soliciting sanity check before I light this new forge

picker77 replied to picker77's topic in Gas Forges

Thanks, Buzzkill. I hope you're right. I was a little surprised how easy it was to light, and I liked not having to fuss with "tuning" the burner. I have several more of the hard splits on hand after covering the cart's top shelf, but probably should look for some insulating bricks to use for heat doors instead? -

Soliciting sanity check before I light this new forge

picker77 replied to picker77's topic in Gas Forges

Re-routed & retested the plumbing, thanks to several helpful suggestions. Lit the fire for first time this morning. Everything appears to work as advertised, idle circuit works great. The flame at all pressures from idle to wide open looks fine to me, but since it's the first flame I've ever put a match to, my opinion is suspect. No doubt it will certainly heat metal enough to move it around, although I have no idea whether it would get hot enough to weld. I included a photo of the interior about 2-3 min after shutoff from a short heat run. That shelf glowed for quite a while. Forge welding is not a concern right now, I just need to learn to hit what I swing at without hitting my poor anvil, which I have named "The Victim". Unfortunately our current string of 100 degree days won't help much in that regard. The "clean work" area/office in the back of my shop is air conditioned, and right now draws me like a magnet! I resized these down a lot, hope they aren't too big. -

Soliciting sanity check before I light this new forge

picker77 replied to picker77's topic in Gas Forges

Thanks, Chris. That's a hard thing to deal with. 56 is way too young! -

Soliciting sanity check before I light this new forge

picker77 replied to picker77's topic in Gas Forges

I've found that the older I get, the more I marvel at some of the foolish things I (intentionally) did and did not die as a result of over the years, and I wonder why the Good Lord gave me a pass so many times. My father passed away at age 53, 50 years ago this month, a few days before the Apollo 11 moon landing. All that stuff constantly on TV lately about the moon landing has been a sad reminder, I'll be glad to see July in the rear view mirror. -

Soliciting sanity check before I light this new forge

picker77 replied to picker77's topic in Gas Forges

Isn't it amazing how quickly metal things can sprout legs? In the Navy yard a few workers (and sailors, too, I have to add) had the attitude that "heck, it's government stuff, nobody will miss it". Once in a while the shipyard CO would have the rent-a-cops do random outgoing vehicle searches at the end of shifts, with occasionally eyebrow-raising results. -

Soliciting sanity check before I light this new forge

picker77 replied to picker77's topic in Gas Forges

Good info, Buzzkill. You pretty much described how I'll be operating with open doors, etc. I had forgotten from my training back in the day that CO doesn't pool like some gases, which is at least a bit reassuring. Heavier than air gases, whether they be explosive or inert oxygen displacement hazards, have always caused my hair to stand on end a little due to Navy experience, years spent in a shipyard/ship repair environment, and later working for Ma Bell data systems in/around cable vaults. Heard a lot of horror stories, even peripherally involved in one or two. That stuff got my attention for sure. Thanks. -

My New Emerson 100# Traditonal Arrived Today

picker77 replied to CrazyGoatLady's topic in Anvil Reviews by brand

Congratulations on that sweet anvil and stand, CGL, and nice work! Dang, the one-up-womanship on here is getting hard to keep up with! -

Soliciting sanity check before I light this new forge

picker77 replied to picker77's topic in Gas Forges

"re-emissive coating"... that would be something like ITC-100, correct? And would that be true no matter what floor material I use? -

Soliciting sanity check before I light this new forge

picker77 replied to picker77's topic in Gas Forges

Gotcha, Frosty. Thanks!! -

Soliciting sanity check before I light this new forge

picker77 replied to picker77's topic in Gas Forges

Thanks, Mikey. -

Soliciting sanity check before I light this new forge

picker77 replied to picker77's topic in Gas Forges

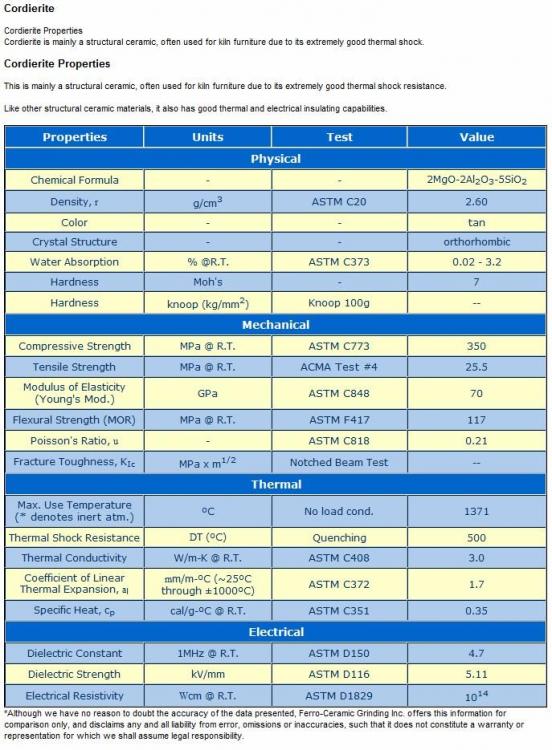

Roger, Mikey. I have taken aboard the advice from you and others such as Frosty and have nixed the QD idea, which made my wallet very happy. Just for drill, I'm also going to change out a few 1/4" compression fittings (that was all the local big box stores had) in favor of flare types. The existing comp fittings aren't leaking (yet), but after hearing several opinions on the less than stellar reliability of compression fittings in gas applications, I thought I'd get ahead of the curve. And while I'm wearing you guys out with newbie questions, I have a possible option on hand for forge floor material: My forge came with a standard hard firebrick split as a floor (on top of insulation, of course). But I happen to have a 14 x 14 piece of 5/8" Cordierite, from which I cut a 4-1/2" x 14" piece (photo below). I know Mikey has not said many good things about Cordierite, but if it's compared strictly to a standard hard firebrick split, would the Cordierite be an improvement? Or, as an alternative, what if I just lay the Cordierite on top of the firebrick (it would stick out each end about 2-1/2") -- Yes? No? And last question (for today anyway), I have some kiln wash mix, so in any case should I apply it to whatever floor material I use? Thanks and have a great Sunday! -

Soliciting sanity check before I light this new forge

picker77 replied to picker77's topic in Gas Forges

Hmm... rethink #26.. You guys always leave me plenty to think about, and sometimes to reconsider. I do intend to run this thing outside, though, one way or another. Too much reading of the CO poisoning threads, I suppose. Plus, back in the day when I was one of several ship repair superintendents at Philadelphia Naval Shipyard, I had one of my Shop 26 guys done in by oxygen displacement down in a lower level tank. Turns out Shop 67 and Shop 56 guys were purging electronic equipment distilled water cooling lines with pressurized freon several decks above, had a leak they didn't know about, and freon sinks like a rock. Inert gas problems (or more accurately, oxygen deprivation) has held a front row pew in my mind ever since. Reading the CO safety threads sort of brings it all back again. Not pleasant thoughts. After seeing photos of all the forges being operated inside shops by IFI members, I wonder about the choices of some of our learned brethren. But as I said before, I'm old and cautious. Thanks, Neil. I'm working on it, and I'll get there, lol. -

Soliciting sanity check before I light this new forge

picker77 replied to picker77's topic in Gas Forges

I'm thinking I'd like to go to high pressure quick disconnect hoses and fittings. For example, it appears that gashosesandregulators.com has an extensive array of this stuff rated up to 250 psi, including stainless steel hoses with QD fittings up to 20' (the long QD hose remains outside, permanently connected to the tank). Although admittedly a stiff one-time cost, it seems that would be perfect for how I'd like to run this forge, namely leaving the 30# bottle outside with long SS hose attached, and wheeling the forge cart out and plugging it in to the long hose with a QD pigtail whenever I want to fire up. Otherwise, without QD fittings, strictly following safety rules, if I want to keep the forge/cart stored inside, I'd have to leave the tank outside and screw/unscrew the regulator's POL connector every time I want to use the forge. I can see that leading to wear and damage to the seals/o-rings on the POL connector, in addition to being a pain. They even sell dust covers for the fittings (similar to those on tractor hydraulics), which should work ok. Only problem of course is cost, about $140 for the 20' SS version. Gulp. Anybody using these, and if so are you happy with them? -

Soliciting sanity check before I light this new forge

picker77 replied to picker77's topic in Gas Forges

Frosty, while re-arranging the plumbing a little we discussed above, I discovered something I didn't know - that shutoff valve that Diamondback pre-installed at the burner is not a 1/4 turn shutoff, it's an 8 or 9 turn needle valve. Having not fired the forge, I never actually operated it - so that was a surprise. As a result, I'm not only moving the main burner shutoff down to the inlet side of the idle circuit, I'm replacing it with an LP gas-rated 1/4" quarter-turn ball valve. Cranking a valve 8 or 9 times to close it when things are on fire doesn't seem to be an efficient way to operate an emergency shutoff, heh. -

Soliciting sanity check before I light this new forge

picker77 replied to picker77's topic in Gas Forges

LOL - now that sounds like something I can handle, Chris. I thought he was talking about some sort of physically hinged steel doors like I've seen on many new forges. -

Soliciting sanity check before I light this new forge

picker77 replied to picker77's topic in Gas Forges

Many thanks to both of you for the helpful advice and timely suggestions! -

I admit to being an overly cautious old geezer, but that's how I got to geezerhood. Anyway, now that my new little Diamondback single burner has its mobile home and the gas piping and idle circuit are completed, I'd appreciate one last eyeball/sanity check from more experienced forum gurus before I actually light it up. All gas threads were yellow-doped, soap tests were done, a few minor leaks were fixed and re-tested, and a CO detector is now installed in the shop. This forge will be operated almost exclusively outside, thus the need for mobility. On really cold days, I'll just shift gears back to stock removal for my knife making. If you see anything sketchy looking or something I might have missed, especially about the gas piping, I'd sure appreciate a heads up. Don't want my wrinkly old butt blown up. Thanks! Oh, and I know it's tall (53" to the forge floor) but so am I.

-

Lots of creativity involved in hardy hole stuff. That hardy you made looks like a copy of the hat on my sister's garden gnome, lol. I'm going to start (and probably stay) simple, with a turning/bending tool, a hot cut, and maybe a couple of fullers. My skills are at such a low level right now I'm at the "gotta start somewhere" stage, but I can already see a need or want for a couple of punches for holes.

-

Read a lot about problems with the well known wide variance in hardy hole dimensions in older anvils causing hardy fitting headaches. My old 100# Kohlswa has what appears to be a 7/8" hole, although a bit rough, so with fingers crossed I picked up a half dozen 4" lengths of 7/8" cold rolled 1018 square stock today (at $1.65 per inch, I might add), and of course they wouldn't go in. However, lady luck smiled for a change, and it was just the rounded corners of the anvil's hardy hole that caused the problem. A couple of minutes on the belt sander putting a small radius on all the sharp corners of the bar stock and they now drop right through with a very close fit, with only a small amount of wiggle. Best part is each of them drops in no problem no matter what orientation I try. So it looks like hardies for this anvil are going to be easy to make. I got lucky this time, and I'm a happy guy!

-

Now that I've started paying attention to it, I see more mentions. Thanks, Buzzkill. Nconoan, I got one today at good 'ol Home Depot, it's a Kidde with a 10-year Lithium battery preinstalled. Around $40 and worth every nickel. For an extra $20 they'll sell you one that yells at you like Alexa in addition to sounding an alarm. I passed on that one.