-

Posts

212 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by picker77

-

Could at least the top be resurfaced by a machine shop or foundry without spending a fortune?

-

iFixit (Google it) is a great repair resource. I've been a member for years, and they have helped me replace several iPhone, iPad, and Kindle batteries, rescue some dead PC and Mac notebooks and laptops, and fix several small appliances - saving a lot of $ in the process. They lead a global revolution against the now common "throw it away and go buy another one" concept. Just two weeks ago I followed iFixit's step-by-step instructions to replace the $3 Lithium Ion battery in my beard trimmer instead of buying a replacement trimmer for $40. A little background in soldering/electronics repair is helpful, but not required. You just need good eyes and steady hands. Oh, and the most important thing that's lacking in a lot of folks: the ability and willingness to [read the manual], an age-old but critically important engineering term.

-

Here ya go, Chris. PM me if you want to come and get 'em, I'm about 4 miles W of Will Rogers airport.

-

PWS, congrats for saving those fine old tools. That bandsaw looks like a mid-to-late 30's Walker-Turner "Driver Line" 12 inch. I rescued a 1935 version W-T several years back (photo attached). Fine old saw, all cast iron, solid as the Rock of Gibraltar and almost as heavy. It's probably the most-often-used tool in my shop.

-

What did you do in the shop today?

picker77 replied to Mark Ling's topic in Blacksmithing, General Discussion

I need to correct a memory blunder re the TD1 tomahawk drift I praised in my initial post: I actually purchased it (along with hammer and mouse drifts) from Amy Pieh at Iron Mountain Forge in Arizona, NOT from Blacksmith Depot as I first stated. My humble apologies to both suppliers. -

What did you do in the shop today?

picker77 replied to Mark Ling's topic in Blacksmithing, General Discussion

Les, it's just a pair of standard old knife blade tongs I usually use for beating around on knife blades & billets up to 1/4" thick or so. It works ok for tomahawk blades like this one, up to about 1-1/2" wide. Above that width I'd have to bend the reins in a little to compensate for the larger bite required, which of course would also mean they would no longer close far enough to be useful in their original purpose, lol. You'd be surprised how fast you can lose track of up and down in the heat of forging (pun intended). The twist on the iron wire was just to keep me straight on what's up and what's down on the blade as I was adjusting & drifting it. A hawk eye will likely always want to fit tighter in only one particular direction, and I found that confusing down and up could be a problem while working with this symmetrically shaped blade. If it was more dramatically shaped with a beard, that wouldn't be a problem. -

What did you do in the shop today?

picker77 replied to Mark Ling's topic in Blacksmithing, General Discussion

A few photos of what the Dunlap wood profile looked like as it was delivered. This was the low grade "reject" they sent me to practice on, but even it had better curly grain than I expected - but only on one side, which was why it was rejected, I'm sure. The profile is a pretty good fit, shown dropped into the eye after drifting with a TD1 drift, which the Dunlap profile appears to mimic closely. Had to heat and drift twice because the first time I neglected to take into account how much the eye as going to shrink after I tapped out the drift and let it cool. Hint: a lot. Now on to grinding, cleanup, heat treat, temper, and finally fitting the handle for real. This first effort is 1018 wrapped to a 1084 bit. I hope the bit weld still looks ok after I grind it back and thin it some. Jennifer, I failed to heed your (and Alan's) advice and didn't belly out the inside of the eye before wrapping and welding, so paid the price by fighting the eye some later, finally got it cleaned up straight after some difficulty. Lesson learned. BTW, that TD1 Drift is what my Grandpa used to call "the cat's butt" for a tool. Saves a lot of hassle. -

What did you do in the shop today?

picker77 replied to Mark Ling's topic in Blacksmithing, General Discussion

I think it was four day in my hands from Fedex. They shipped the same day I called them. I"m a small customer, I only ordered four, all in curly maple. Two in the fancy grades, and a couple in standard grade, plus some of their special maple stain. REALLY nice wood, even the standard grades, can't wait to use it. Nice folks and very knowledgeable. It's best to call them and do the order on the phone. Most of their business appears to be in gunstocks in wood of all kinds, I think tomahawk handles is just a sideline. But since they do custom profiled gunstocks for a zillion different kinds of rifles, they likely have a good array of duplicating routers and milling machinery. Their website is pretty informative but they don't do "shopping cart" type sales online, which I kind of liked - actually working with a human. -

What did you do in the shop today?

picker77 replied to Mark Ling's topic in Blacksmithing, General Discussion

I dearly hope this reply does not get me "__ penalty points which shall never expire" because I'm not selling or recommending anything, just stating a personal experience, but re Jennifer & Good's query: On advice from Alan Longmire's in his extensive wrapped hawk tutorial/WIP, I ordered and received several profiled handles from Dunlap last week. They even tossed in a "reject" handle (rejected due to low-grade grain, not a profiling error) for me to practice on so I didn't have to possibly butcher up a nice premium curly maple example while fitting it for my first try at a wrapped hawk. Wood is beautiful and the machined profile (according to my Blacksmith Depot TD1 drift) is right on the money. I admit I have not tried the other two suppliers, they certainly may be just as good, I only mention this because it seems to me we should pass the word among us when a good source of blacksmithing materials is encountered. -

What did you do in the shop today?

picker77 replied to Mark Ling's topic in Blacksmithing, General Discussion

Going to try a few folded eye hawks, but had no hammer/hawk tongs. So today I made this crude pair from 20" pieces of 1/2" round. Amazing how hard it is (for me) to get the second tong handle to be a nice clean mirror image of the first one. Ha. Also tried another dry weld test project, 1/8" 1084 sandwiched between two pieces of 11 gauge mild sheet. Welding went fine, so I did a "test" flat grind on one side of part of the resulting billet and etched it. Very happy it went so well, I really like the look of a dramatic transition line between MS and HC, I actually like the looks of low-count san mai better than zillion-layer "damascus". Now I'm gonna have to make some knives that way. -

Lucky you! That's an ultra sweet find. I have a Baldor 1800 RPM buffer that cost me nearly $400 several years ago (and I had to build my own stand for it!). Baldor makes absolutely top quality stuff.

-

Well, it was mainly just idle conjecture, not gonna happen for lots of reasons, some of which you mention.

-

Oh, it can do that all right. But I use it mostly for road maintenance and brush/tree clearing. The rear aux hydraulics are currently hooked up to provide tilt/trim for a 5-1/2' box blade, or (by swapping aux hoses) run a small two-finger grapple on a toothed bucket for grabbing & lifting logs, rocks, stumps, etc. to a max of about 1100 lb. If the pump provided sufficient volume, I suppose I could run a pair of long lines from a press located inside the shop out the door to the tractor, turning the tractor into sort of a very large 4WD mobile power pack. This is not a big farm tractor, just a little JD 3032 compact, and as I recall the pump is only 6 gpm or so at around 2200 psi. Maybe not enough flow there for forging. The tractor is normally parked inside the shop, but of course I'd have to move it outside to power a press to keep it from freaking out my CO detector, not to mention killing the press operator.

-

Not sure if there would be sufficient gpm, but could the aux hydraulic system of a 30-40hp tractor power a homebrew shop press?

-

Pnut, here's what I cut up to 4-1/2 x 9 to use for my floor. [Commercial link removed per TOS.] Cuts easily with a 7" diamond circular saw blade (and breathing apparatus, of course). Cordierite is NOT high alumina as Frosty pointed out, but even coated with Matrikote it suffered from flux adherence, which kind of surprised me.BTW, Frosty, I did remove the hard brick floor piece when I put in the kiln shelf. FWIW, overall, I've been very happy with my DB forge, my only mild regret being maybe I should have sprung for the two-burner. But that's a good excuse to build one. Have fun!!

-

I painted Matrikote on the walls, but not the ceiling, and when I put the kiln shelf floor in I painted that with Matrikote first (too thick, it flaked some later). But the big thing was borax flux immediately ate a shallow crater in the middle of the kiln shelf (actually, I made the 2x3x1/8" crater when I later chipped off the hardened/stuck flux). I put in another 4-1/2 x 9" shelf piece, (uncoated), and that has held up fine since, mainly because I do not use flux any more. When I do pattern welds they are done dry. I've never tried any exotic super-multi-layer folded patterns, only simple non-folded minimal layer count billets. The Matrikote on the walls has held up ok, but has flaked some, I tried to put it on too thick, should have listened to Frosty. The ceramic board is pretty firm to the touch, but if treated roughly it will gouge and pill up some in little mini-rolls of fiber. Coating helps of course but as I said some of my coating flaked off. I just try to stay away from the walls.

-

Yep, sure did. I can't tell you much about floor longevity because I covered the floor with a piece of 5/8" thick kiln shelf cut to fit. The kiln shelf held up fine so far, although it did get cratered a bit (maybe 1/8" or so in the center) by flux the one time I tried flux welding in it. Since then what welding I've done has been dry. The ceramic board that DB uses is pretty stiff and reasonably solid, but it will still shred up a little if you get rough with it. I've never tried doing castable for a floor, so can't really tell you if the kiln shelf is better than that or not. The big advantage is the KS is (fairly) easy to cut to size, and quickly replaceable by just sliding in a new shelf on top of the ceramic board the DB came with. The downside, of course, is you lose 5/8" of height from an already pretty restricted working space. So far, I'm very happy with this DB forge, although I'm beginning to wish I'd gone with the two burner version, simply for convenience when heat treating longer knife stock (I don't have a heat treat oven). But for 99% of what I do it's perfect. Easy to light, heats quickly, just works as expected. A bonus is it seems to be very frugal on gas usage. I'm using a lot less fuel than I expected to need. The idle circuit helps, but even without that the forge lining seems to hold heat quite well at pretty low gas pressures.

-

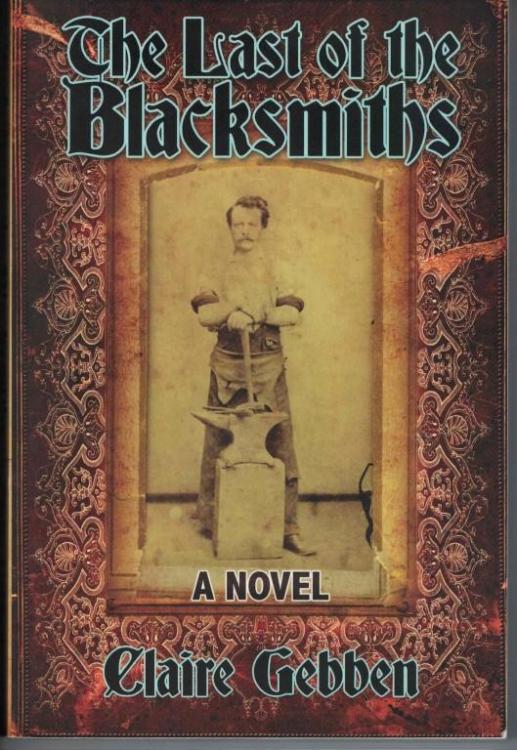

334 pages, Historical Fiction, but seems to follow closely the story of an actual German immigrant who made his way as a youth to the Cleveland, Ohio area in the mid 1800's to apprentice as a blacksmith in a wagon-building business. Well written and enjoyable read, but the most interesting thing to me was the apparent accuracy of the terminology. The writer (a lady) had a solid handle on the language of blacksmithing during the period, especially where wagon-building and working with wrought iron was concerned. A novel, not a technical treatise, but enough iron-pounding involved to be interesting.

-

What did you do in the shop today?

picker77 replied to Mark Ling's topic in Blacksmithing, General Discussion

Suspicions confirmed, TP. Yep, not so long ago we had half a dozen little freely distributed "classified ad rags" like the Thrifty Nickle, Penny Trader, etc. in the newspaper rack at convenience stores. A few were pretty thick. Even as recently as the early 2000's I routinely stopped by a 7-11 every Friday AM to get the latest. They were little gold mines if you jumped on an ad soon enough, as you did. Fleabay killed off much of that, and then CL came along and delivered the coup de grace. I miss them, but I suppose time and technology does move on. I use an E-reader for many things now, and if I do pick up a real book I sometimes catch myself tapping the right edge to "turn" the paper page, or trying to zoom a printed image by spreading thumb and finger. -

What did you do in the shop today?

picker77 replied to Mark Ling's topic in Blacksmithing, General Discussion

SFC Snuffy, nice solid chunk of work, not likely to fall apart any time soon, ha. I've looked off and on for a while, have never seen a decent swage block for sale in my area. They are much less common than anvils, which are pretty rare themselves. BTW, would that by any chance be Chief Shipfitter Snuffy? If so, thanks for your service! -

Dasher, you're right. It's called Northwest Cape for a reason, ha. Technically, I think I would have enjoyed the job (Electronics Maintenance Officer), but boy, it's definitely out in the sticks. Frosty, I've already told my two sons to bring U-Hauls behind their trucks when they come to the funeral.

-

Sounds like me, I'll be 78 next month, I'll have to leave instructions for the wife to make sure she doesn't yard-sale this grinder for $30. Looks like you have a great setup for slack-belt grinding. I'll bet you will also eventually want to add a removable tool arm holder of some sort, so you can run home brew tool arms with a platen and a contact wheel one of these days. Neither are hard to add, the tool arm/contact wheel was easy, but from my experience I recommend purchasing a professionally fabricated platen/wheel setup from the outset. I initially made a platen using skateboard wheels and it worked OK most of the time, but wheel alignment on a platen needs to be perfect, and my "precision" home shop fabrication/assembly tolerances (add one more washer here or there, lol) resulted in intermittent tracking problems, depending on which side of the belt I put pressure on. After I was making knives more often I finally bit the bullet for the real deal, and it runs smooth as silk. Very well spent $90. BTW, in 1978, when the Navy was scheduling my next duty transfer after three years in Hawaii, they offered to send me on a 3-year assignment to the USN communications facility near Perth. But with two boys in high school at the time I opted to go to the U.S. east coast for my final tour before retirement (I retired the first of three times in 1980). I think I would have enjoyed a down under tour, have always liked Oz folks, they are salt-of-the-earth type people. G'day and enjoy the grinder!

-

I suppose there is an exception to every general rule, and Pnut is correct that a TEFC (totally enclosed fan cooled) motor is definitely preferred for longevity. I built the pictured 2x72 grinder in 2006. The motor is a non-enclosed 1.5 HP 120V 3450 RPM capacitor-start fan motor rescued from the attic when we had our central A/C replaced back in 1996. The shaft drive wheel is 4" diameter and rubber covered, the tracking wheel was recently replaced with one from OriginBladeMaker, and my original skateboard wheel platen setup (which never worked well) has been upgraded to OBM's nicely machined platen/wheels, which run smooth and true. Every few months I suck the grinder crap as best I can from inside the motor with a large shop vac, and blow it out with the shop air hose, but that's been it for maintenance for the past 13 years. I used it daily and pretty hard, and it still runs just fine. Because I really would like to have speed control, I'm getting ready to upgrade with a VFD and a new 2HP 3-phase TEFC motor. I also have an accessory tool arm with an 8" rubber covered contact wheel that works really well. I guess my point is don't hesitate to at least temporarily make use of a non-enclosed motor if that's what you have and cost is a factor at the moment. You can always upgrade later as funds permit. That's what worked out best for me.

-

No problem, Gill. I'll just do a bit more experimenting. There's a WoodCraft store within driving distance from me that carries a lot of different dyes and stains. They also stock some small "turning block" sizes of exotic woods for carving and ink pen turning, although like everywhere else their exotic wood is also exotically priced. From my guitar building days I think probably alcohol-based dye will be the way to go. BTW, for the knife makers among us, a good source for handle finish materials is Stewart-MacDonald's website, it's the cat's butt for almost any wood finishing/staining material you could think of, and is the Amazon of the stringed instrument materials supply world. If they ain't got it, you don't need it.

-

Gill, nice knife! Did you dye the scales yourself? If so, what did you dye box elder burl with? Alcohol based dye? Water based? I have a pretty good stash of beautiful stabilized 1-1/2" x 1" x 6" blocks of BEB, purchased 10 years ago when you could buy this stuff cheap. Now it's ridiculously priced. I love the wood, but would like to try some darker dyes on it. So far the prettiest finish I've come up with is sand to 400, followed by a couple of coats of Watkins Danish Oil in dark walnut, followed after a couple of days with 1800 RPM buffing with green cutting compound on a sisal wheel, and finally white rouge on soft cotton cloth wheel.