-

Posts

212 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by picker77

-

Amen, I'll file that salt tidbit away in the very useful pile. Thanks, Frosty. 1/4" is pretty thick, but from all the dire heat treating warnings I've read from Lo, the many steel experts around (not on IFI, I might add), I was afraid over-hardened steel might explode like a china cup if struck, dropped, or looked at sideways, and I smacked this stuff pretty hard. But no matter what it is, I'm thinking it might make some really excellent hardy tools if tempered down to something reasonable so I don't ruin a hammer face on it. No idea how hard it would be to move around on an anvil when heated, though. My ignorance of working mild steel is only exceeded by my ignorance of working with tool steel. Of course, there's one way to find out! They say ignorance is bliss. No wonder I smile a lot. I suppose I was secretly hoping it was either 4140 or 1045, either of which ought to be good for hot & cold cut tools, punches, etc..

-

Ok, because I rescued so much of this stuff yesterday (hoping it was a smart thing to do at 35¢ a pound!), this morning I made an attempt at identifying the steel in this shafting. Now I need some experienced opinions: I cut a 3" or so piece off one end of one of the three 10' or so pieces with a handheld band saw that has a new Starrett blade (the shafting appears to cut quite a bit harder/slower than plain old 1" mild steel rounds, so I presume (a) it's tool steel of some kind, and (b) it's currently annealed. A good shop file grabs it about like mild steel. I then cut three 1/4" slices from the 3" piece, notched each of them for identification, heated them to non-magnetic, and quenched them three different ways: #1 slice was quenched in canola oil, resulting in about RC50-55, if my guess using one of those 6-file RC hardness Identification sets is anywhere near the mark. A new shop file will grab it with some pressure, but without much pressure will skate on it. The #2 slice was heated and then plunged into water, and it hardened like crazy, will skate both shop and test files like glass. I can hardly make a mark on it with anything. I'm guessing at least RC 62 or 63..??. The #3 slice was heated and left to cool in ambient shop air, which resulting in zero hardening, I can't tell the difference in it from annealed state using files. Figuring I had made the water hardened slice extremely brittle, I clamped both #1 and #2 slices (one at a time) halfway into a big bench vise, covered them with a shop towel, and went to town on them with a big flat nose punch and a medium sized hammer. I totally expected the #2 water-hardened slice to break, shatter, split, or something. NADA. I couldn't seem to do anything to either slice, and in fact I finally quit for fear of busting a cast iron jaw on my bench vise. Since it hardened fairly well in oil, I think it must be too high in carbon to be 1018, so maybe it's 1045?. But if so, I don't understand why it hardened so much in water, yet still remained tough enough to withstand serious sideways punishment without cracking or breaking. Could it be W1, O1, 4140, or some other type of tool steel? It's important to me because I have so much of it, and I want to use it for things that make sense. Photo attached.

-

True, but I personally dislike using angle grinders, a torch is a lot faster and quieter. I probably developed my dislike of them after years of grinding out my crappy looking stick welds before I finally bought a MIG unit. Sold my Lincoln AC-DC 225 a couple of weeks after that without a second thought. Of course, some might say I traded ugly deep beads for pretty shallow beads.

-

Having a little shopper's regret, might go back and grab one of those big coils tomorrow... after all, I do have a cutting torch!

-

Chris and I hit the same place, I was a few hours ahead of him (got in and out while it was cloudy and a little cooler. When the sun popped out, I was out of there). Found pretty much what I needed and then some, brought home 320 lb of stuff even after passing up several things I really wanted to grab. The haul: About 28' of 1" machined shafting that I think might be 4140 (has a machined-in key way), a 6x8 3/8" wall I-beam for a post vise mount, a couple of broken 1-1/2" truck axle sections (future hammers or punches?), an 11x20x1" section of bolt-on bulldozer or road grader blade that might end up being the base for the post vise, some large angle, several feet of 1" mild steel round, and a 5' piece of welded iron fencing made with 1/2" solid square stock. Didn't see much round stock in the smaller sizes, mostly 1" and up. Saw some BIG coil springs, but forging stock that size is a bit above my pay grade right now. Not sure I could even straighten a piece of it out, lol. So I'm still looking for smaller coil and leaf stock. Nice find, Chris, that's the size I was looking for!! Here's the coils I saw instead:

-

Thanks, George. I'll keep that in mind. Sometimes when I get into polishing something I never know when to stop, ha. They probably won't stay shiny very long, I don't doubt I'll have them roughed up some in short order just from use. Was up your way (well, sort of - Shell Canyon area) recently, it was nice to breath that cool, dry Wyoming air again. Around here lately, breathing requires cutting off a chunk of air with your pocket knife and chewing on it.

-

Thanks, folks, for the encouraging words. Bigfootnampa, I think I'll pass on owning a Hofi -- the home forge is paid for, and we don't want another mortgage. Besides, a hammer like that would be wasted on a newbie like me until I've developed enough of a feel to appreciate it.

-

Soliciting sanity check before I light this new forge

picker77 replied to picker77's topic in Gas Forges

Thanks, Buzzkill, and I hear you loud and clear. I'm often guilty of staying in the shop an extra hour to "finish up" something when I know I'm already too tired, and at my age I pay the piper later, especially the next morning. My mind still thinks I'm 45, but my body knows dang well better. -

FSO's (Fork-Shaped-Anvils) abatch

picker77 replied to picker77's topic in Anvils, Swage Blocks, and Mandrels

Greetings, Steve S., and aloha to you and your family. We vacationed on the Big Island and on Kauai a couple of times while living in Hawaii, but never lived on either island. Both are beautiful islands, Kauai is especially a stunningly beautiful place. I'm glad we got to experience the islands back in the day, but too crowded and too much traffic now, so I have zero interest in going back. My favorite musician is still Gabby Pahinui, I listen to his slack key stuff in my shop all the time. -

I've been so wrapped up in getting a working forge setup done I neglected until now to clean up and dress my meager collection of new and old hammers. Finally finished, I hope. Although I'm a first timer at hammer dressing, I tried to follow the advice and rules I read on IFI about how to do this. They look pretty good to me, and if I can learn to use them correctly, I believe they will do the job. Left to right in the photos of five hammers, are a 2 lb rounder, a 3-1/2 lb straight that was my grandfather's, a 2.2 lb Swedish cross, a 1-3/4 lb Swedish cross, and finally a 1 lb cross pein that also was my grandfather's (I see I left out the small 1-pounder in one of the photos). The two that were my grandfather's are from the early 1900's, probably about 1915 or earlier. I assume that 3-1/2 pound straight pein is way too much hammer for a beginner, but dang, it feels good in my hand. Not pictured are 8-lb and 4-lb sledges, and my all time favorite "speed wrench", a fat little short handled 3-lb sledge I've owned since my 20's (50+ years), and several miscellaneous dead blow and different durometer rubber hammers. When I dragged them all out at once I was a little surprised at how many hammers I've collected over the years. Fortunately my wife didn't come out to the shop while I had them all laid out, that would probably have been hard to explain, lol.

-

Soliciting sanity check before I light this new forge

picker77 replied to picker77's topic in Gas Forges

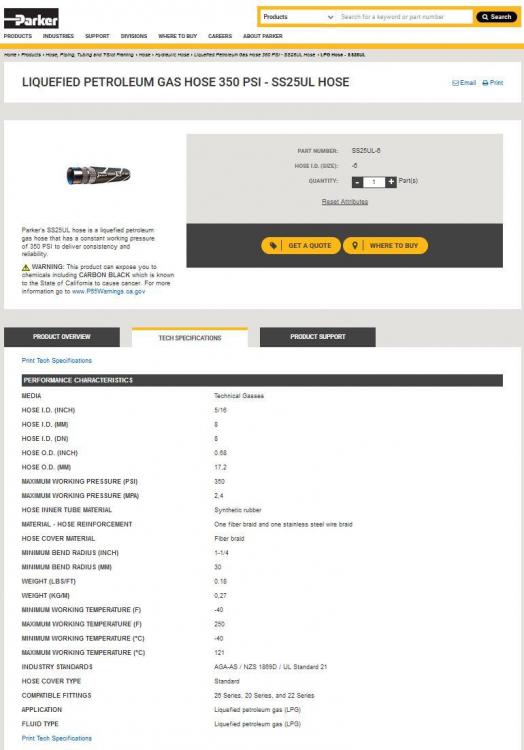

Made a few last minute tweaks to the cart setup related to operating convenience and LPG safety, and thank you to all the helpful suggestions from members in those areas. There is now 18' of Parker super-hose between me and the tank, and the tank itself will permanently live in a weather-sheltered alcove just outside that man-door in the photos. Plenty of length with the new hose to allow reasonable freedom of movement for the cart, and I honestly doubt you could cut that hose in one swing with a fire axe. It took the propane dealer a while to cut it using an air-powered cutoff tool. It is very tough stuff. Also added front and back basic sliding door to help trap heat, plus a better front support for heating longer stock. I will probably coat the kiln shelf floor and maybe the walls with Matrikote yet before I'm done, since that's easy to do and I have the Matrikote in hand, but I need to study up on mixing and applying it. Lastly, I finally had some time to dress my small selection of old & new hammers (photos in hammer forum). About ready to actually launch this thing and beat some iron. Only problem right now is motivation, 102 degree temps accompanied by ugly humidity levels make me lean toward the A/C instead of the shop. It's August in Oklahoma and I'm used to it after all these many years, but that doesn't make it any more pleasant. -

FSO's (Fork-Shaped-Anvils) abatch

picker77 replied to picker77's topic in Anvils, Swage Blocks, and Mandrels

Frosty said: "Chris, Picker: You two could use a version of Thomas Powers ID method. He wears a Hawaiian shirt and Lederhosen, Ala Rufo. If I ever get to an event where I'm not already known I want to find a snowman head, hat." Frosty, that must be a sight to see. But when I want to stand out from the crowd, I wear one of my kilts. My family tree sprouted just north of Glasgow back around the year 1100. Invariably, somebody will ask why they call them kilts. The answer: "Because over the years, we have kilt anyone who called it a skirt. That's what this Sgian Dubh is for". -

FSO's (Fork-Shaped-Anvils) abatch

picker77 replied to picker77's topic in Anvils, Swage Blocks, and Mandrels

DHarris, it's easy to get there from Purcell. Take I-35, get off at the SE 59th exit, turn left (west) on 59th, turn right (north) on Byers, and then right (east) on SW 55th. The entrance is 1/4 mile down, on the south side of SW 55th. Piece of cake. -

FSO's (Fork-Shaped-Anvils) abatch

picker77 replied to picker77's topic in Anvils, Swage Blocks, and Mandrels

LA Recycling, 500 SE 55th, Oklahoma City. Can't pinpoint it exactly, but somewhere about in that yellow-circled area are those bigger forks. Hard to miss, there are many dozens of them in one concentrated spot, near the north fence. That entire NW section all around the yellow circled area on both sides of that pathway is the "retail" pick area.This photo only covers the western half of the place. It's big! No problem, Jennifer. Us newbies don't get a chance to poke fun at you forum "old hands" very often. Lots of witty folks populate IFI, makes for some enjoyable reading. -

FSO's (Fork-Shaped-Anvils) abatch

picker77 replied to picker77's topic in Anvils, Swage Blocks, and Mandrels

I plead guilty to over the top tongue-in-cheekness in the thread title. But honestly, I didn't think it was obtuse enough that it would take a week for the LED to come on, especially with you two, lol. -

FSO's (Fork-Shaped-Anvils) abatch

picker77 replied to picker77's topic in Anvils, Swage Blocks, and Mandrels

Maybe that 20¢ buy price I thought I heard was actually 4¢. No idea how they handle small time piece-by-piece buyers... maybe weigh your vehicle, have you go load up, and come back over the scales, assuming you dare drive your Michelins over that "road" through the middle of the DIY yard, that is. -

FSO's (Fork-Shaped-Anvils) abatch

picker77 replied to picker77's topic in Anvils, Swage Blocks, and Mandrels

Nope, that wasn't me. I do remember that guy, though. I look a bit rough, but not THAT rough (yet). And I'm glad to hear that wasn't you, ROFL! That poor little dog had such short legs the guy had to finally pick it up and carry it, ha. Thanks for location info, I'll eyeball that area next week sometime. A file won't tell you much about HOW hard something is, only that it's mild steel or hardened. But you can easily feel the difference between a file "skating" over hardened metal and digging into mild steel. I have one of those 6-file Japanese hardness test file kits, but there's a practice/learning curve to effectively use it. However, if used carefully and with some practice you can pretty well nail down hardness within a five point HRc range. -

FSO's (Fork-Shaped-Anvils) abatch

picker77 replied to picker77's topic in Anvils, Swage Blocks, and Mandrels

Thanks, Daswulf, I'll look into that. And yes, a dozen Krispy Kremes or Dunkin's is the master key lots of places, lol. BigGun, hadn't thought of a lot of those items being useful. Gosh, sounds like I just need to go to the junkyard and stick an '86 Buick in the back of my truck, ha. Chris, you might want to throw a small file into your scrounging tool kit, to help guesstimating hardness. I'm right there with you on the grandkid thing, we have 5 kids, 14 grandkids, and either 4 or 5 great-grandkids (I think I'm losing track of those, ha). Anyway, I'll probably run into you over there again. I'll check out those I-beams you mentioned, might be one of those would be just what I need. For ID I'm old, 6'4", 240 lb, grey beard, grey hair, John Deere cap, always wear shorts unless it's below freezing. Not sure about the 35¢/lb thing, the guy yelled it over his shoulder as he was walking away, but lots of racket there at the time. Sounded about right. I think they pay around 20¢/lb for steel when buying. If I run into a good source of used 5160 in my travels I'll let you know. -

FSO's (Fork-Shaped-Anvils) abatch

picker77 replied to picker77's topic in Anvils, Swage Blocks, and Mandrels

Roger that BigGun, thanks for the caution. I'll remember to bring a pocket hacksaw. One of the things I expected to see simply wasn't there in any quantity, and that is leaf springs. I'd like to find a few smaller size leaf sets, like those found on compact/sub-compact cars, boat trailers, etc. A few small torsion bars would be nice, too. One of the worker bees told me they usually shred whole cars and smaller trucks without messing with parts - too labor intensive, I guess. I"ll check some auto salvage places next. More likely to find them, but unfortunately there they'll be priced by the piece rather than by weight. -

FSO's (Fork-Shaped-Anvils) abatch

picker77 replied to picker77's topic in Anvils, Swage Blocks, and Mandrels

Dang, BigGun, that would be some serious post vise. Chris, "up and running" is a relative term. You're welcome to come over any time for a cup of coffee, but I'm so barely out of the starting gate on this stuff I'm still setting up equipment. So forging something in my shop would be the classic definition of the blind leading the blind, lol. Still got my eye out for an anvil for you, but nothing so far. Jennifer, if you'd like I'll get you an estimate to crate and ship you a couple of those big forks. Heh. -

FSO's (Fork-Shaped-Anvils) abatch

picker77 replied to picker77's topic in Anvils, Swage Blocks, and Mandrels

Chris, I'll bet I saw you there, browsing around in the same general area around 12:30 or so. Bit of grey hair, glasses, 70's? We were the only two old guys around back in that area. Those big forks back there are really something, aren't they? I think I'm going back Monday and pick up a couple of those welded iron fence sections (lots of 1/2" bar stock), and I spotted a ready-made base for my post vise, too. It's 3/8 or 1/2 plate, already laser-cut into a fan shape covering about 120 degrees of a circle, maybe 30" or so edge to edge. Just need a stout chunk of girder to go with it, and Lord knows they have lots of that. -

Browsed the "retail/DIY" area at LA's Recycling Center in SE Oklahoma City today, looking for some 5160 leaf springs and maybe some coils. My first time there. Several acres, more steel than I could get my mind around. Lots of big boy stuff. I believe the walk away price is a flat 35 cents a pound for anything a magnet will stick to. What surprised me was the number (literally hundreds) of forks of all sizes. Piles of them, ranging from this little sample basket of "normal" size forks up to a few in the "Dude, are you kidding me??" category. If you are in the central Oklahoma area and want to get creative anvil-wise (and you have a large cutting tip for your torch or a plasma cutter) there ya go, but bring friends if you want one of the big ones. There were also several scrapped backhoe/excavator buckets in smaller sizes from 12" up to maybe 24", with teeth still intact.

-

Soliciting sanity check before I light this new forge

picker77 replied to picker77's topic in Gas Forges

Thanks, Mikey. Glad to hear there's not too much to worry about regarding compatibility between the available coatings. Picked up some practice steel today, looking forward to heating it up and beating on it. Just as soon as our heat index gets below 100 degrees, that is. ha. -

Soliciting sanity check before I light this new forge

picker77 replied to picker77's topic in Gas Forges

Glad to hear that, Buzzkill, thanks! That's just what I'm intending to do. I'm headed over this morning to pick up a few 10' lengths of hot rolled in 5/16, 3/8, and 1/2" for practice material. -

Soliciting sanity check before I light this new forge

picker77 replied to picker77's topic in Gas Forges

Thanks, Mikey. Got the tank proximity safety issue taken care of (now have 18' of super duty Parker SS25UL LPG hose between the forge cart and tank), but nobody had yet answered the flame shape/color question. I was beginning to wonder if it was so bad that everyone was avoiding talking about it, lol! I also added front and back sliding "barn doors" made from hard firebrick splits cut in half. Not sure yet exactly how to place them (how close to the front/back openings, how much of a breathing hole to maintain, etc.), but I will figure that out. I have some Matrikote coming from Wayne, would it be beneficial to use it to coat the floor (5/8" Cordierite kiln shelf), and/or the rigid ceramic fiber board walls & ceiling? I also have some standard powdered kiln wash available if needed. The forge itself appeared to work perfectly right out of the box (a testament to Diamondback's design and build quality), so I don't want to start fixing what ain't broke -- but the Matrikote, at least on the kiln shelf floor, seemed like it might be a good idea. When I finally do get around to welding, I want to minimize flux damage, and I had some idea in my mind that Matrikote would help with that.