Eventlessbox

Members-

Posts

303 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Eventlessbox

-

What did you do in the shop today?

Eventlessbox replied to Mark Ling's topic in Blacksmithing, General Discussion

My oldest son has finally moved home. At 14 he has claimed my 12# apprentice sledge and spent today starting his first spike knife. One of the best days ever -

I have the 110# Kanca. Have been using it for over a year and it has held up extreamly well. I am a relatively new smith and have missed blows. The face has shown no sign of the miss.

-

What kind of shield am I making?

Eventlessbox replied to Eventlessbox's topic in Cold Worked Iron and Steel

Good to know. Lessons learned for next time.- 11 replies

-

- shield

- roundshield

-

(and 1 more)

Tagged with:

-

What kind of shield am I making?

Eventlessbox replied to Eventlessbox's topic in Cold Worked Iron and Steel

Oh I’m sure if I sheild bashed with this it would do some real damage. Also with the strap/handle my hand is far enough back to jab with the rim. It is defiantly heavy but I don’t think it is so heavy as to be a hindrance with its mounting.- 11 replies

-

- shield

- roundshield

-

(and 1 more)

Tagged with:

-

What kind of shield am I making?

Eventlessbox replied to Eventlessbox's topic in Cold Worked Iron and Steel

Nope not historic aimed at all. Just an experiment with free scrap. Just wasn’t sure if it qualified as a specific type of sheild. It did turn out heavy. Though with the strapping and grip it’s not super bad. May add a shoulder strap to distribute some of the weight.- 11 replies

-

- shield

- roundshield

-

(and 1 more)

Tagged with:

-

So I decided to make a shield out of the bottom of a salvaged pressure tank for a water system. Im liking how it’s going so far but don’t know what kind of shield it is. Approx 20” diameter. Peak of the dome is 3”. It’s looking like the weight will be just short of 10 lbs. The steel is approximately 1/8” thick. And the outer rim is cut to include an original seam so it is a bit over 1/4” thick. Still figuring out the straps.

- 11 replies

-

- shield

- roundshield

-

(and 1 more)

Tagged with:

-

I have collected all the components for my press. Would love any input on ways to assemble and mount before I start that phase. The motor is a 5.5HP 110v. The pump, valves and tank are off an old tractor. The cylinder is 4” bore and is brand new. I’m not positive but my math puts it at a 16 ton press power. I’d love if someone could check me on that.

-

What did you do in the shop today?

Eventlessbox replied to Mark Ling's topic in Blacksmithing, General Discussion

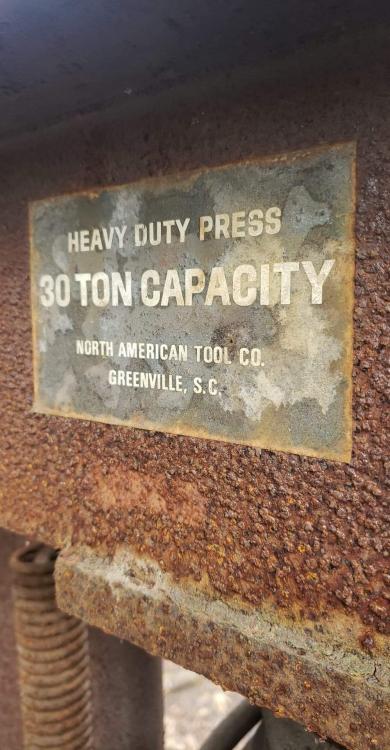

Started the canabilizing of my old broken tractor. Hydraulic control valve and hydraulic fluid holding tank with filter assembly. Pulling the pump next. Have a 30ton shop press frame I have made an agreement to buy which I will be reinforcing with additional steel. And if I’m lucky then I might be able to use a piston from the tractor as well. -

What did you do in the shop today?

Eventlessbox replied to Mark Ling's topic in Blacksmithing, General Discussion

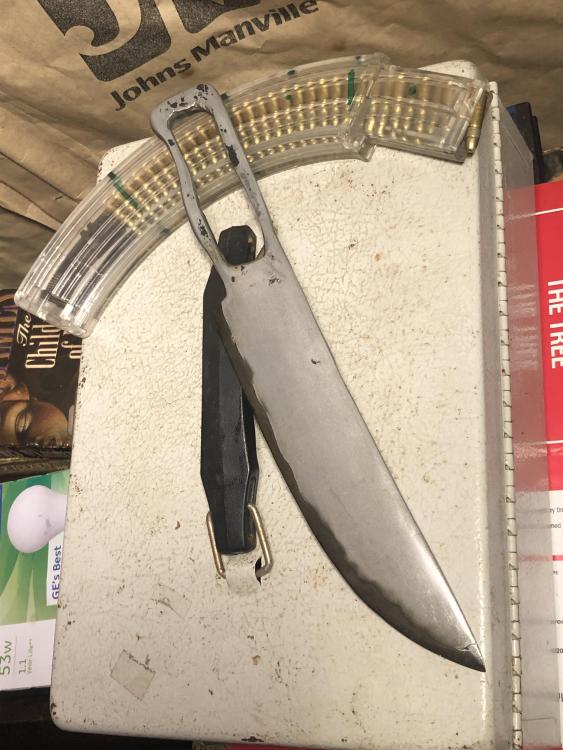

Knocked out a quick little San Mai throwing knife/rope dart ( depends on if it throws like xxxx). 80CrV2 between mild “bread”. Handle was slitted, drifted, thinned over the horn, then knocked parallel. It sucked. Lol. -

-

What did you do in the shop today?

Eventlessbox replied to Mark Ling's topic in Blacksmithing, General Discussion

-

What did you do in the shop today?

Eventlessbox replied to Mark Ling's topic in Blacksmithing, General Discussion

Working on this. Blade is double twisted 12 layer pattern weld. 1095/15n20. The guard is wrought. Have a big cube of wrought for a pommel as well. Forging that today. Handle is going to be leather wrapped wood. Thinking with some twine risers(correct term?) underneath. Super stoked. A dagger is one of my bucket list knives. And high up the list to boot. Also the fuller was forged in not ground. -

What did you do in the shop today?

Eventlessbox replied to Mark Ling's topic in Blacksmithing, General Discussion

-

-

-

What did you do in the shop today?

Eventlessbox replied to Mark Ling's topic in Blacksmithing, General Discussion

-

What did you do in the shop today?

Eventlessbox replied to Mark Ling's topic in Blacksmithing, General Discussion

Neil, I always take info as an opportunity for improvement. Thanks for taking the time to give it. -

What did you do in the shop today?

Eventlessbox replied to Mark Ling's topic in Blacksmithing, General Discussion

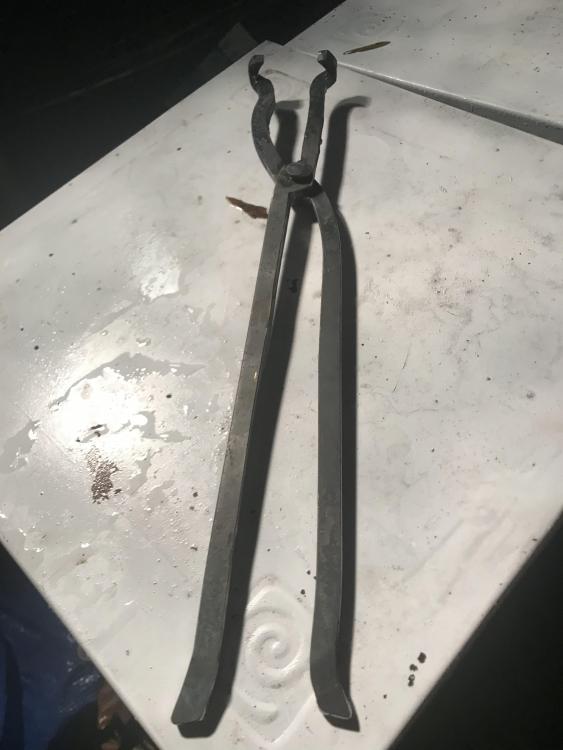

Finished a pair of offset blade tongs today. My second pair of tongs I’ve made. First rivet, forged down from parent stock. Great learning experience. Super stoked with how they turned out. -

Center punch number two from a large Allen key. Changes made from first to reflect group feedback. Note domed striking end. Cold center-punch so shorter length. Tip brought to non-magnetic to an inch down the shank. Quenched in warm canola. Quick grind to reveal clean metal. Shank heated to glowing and temper brought to tip with tip reaching pale fading to dark wheat.

-

First center punch. Really pleased.

Eventlessbox replied to Eventlessbox's topic in Slitters, Punches, Drifts, etc

Love this. Learn something new every day. Shame i'm a loose that forge finish though. Love that colour I’m honestly considering just making a second and keeping that one as a fidget. If you put it tip down and run your hand up and down it it spins in a really satisfying way. -

First center punch. Really pleased.

Eventlessbox replied to Eventlessbox's topic in Slitters, Punches, Drifts, etc

Lol. Yes. I need to proof read better. Very much non magnetic. If I could make it nonmetallic I’d win a Nobel prize prolly. Lol. The tip picked up a light straw. -

First center punch. Really pleased.

Eventlessbox replied to Eventlessbox's topic in Slitters, Punches, Drifts, etc

I’ve always done a camphered(sp?) edge heat treated the first inch to non metallic. Quenched in oil. Quick hit with a belt to clear scale. Then slow heated the shank in the dragons breath of the forge till the temper line got to right where the spiral ends and then stopped the heat spread. Buffed on a belt for apperiance -

-

Thanks for the feedback. The BLO was for the handle wood. Not the blade itself. Rhitee: yep. The fit and finish is defiantly a focal point. Not something I’ve done a lot of so it is going to be the biggest challenge i think

-