-

Posts

807 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by JPH

-

Frosty: Sal ammoniac does help a bunch with SS welding..here again..proper care must be taken...just as with everything else actually...play safe or loose something... JPH

-

Frosty...Weeelllll yeah...fluorspar can be rather a nasty thing at welding temps...but if you know how and take the proper steps and all... next installment later today.. FAB- JPH

-

Frosty: You sure do and then a couple of other things as well... I am rather reluctant to give out this flux due to the fact that if you don't know exactly what you are doing it can mess you up beyond recognition in a second.. I will say that it is a more aggressive variation of my "Steel Glue" flux that I have been using over the years... JPH

-

Eventless...I use them as you see them...these are 0.004" thick.."paper thickness"...next installment follows below.. JPH Next installment: First two photos are the ladder rungs cut into the bar... I do this using an angle grinder and a 1/8" thick steel/metal cutting disc.. The grooves are offset from side to side and abut 1/3 the way down from the flat as shown in the second photo. This piece is 14" in length at this time.. The third photo shows the flattened out bar with the surface hammered out bringing the "ladder" pattern out. the fourth photo shows the drawn out tang and the basic forged blank. The blade section is now 18" in length. Photo five shows the blade that has been heat treated and finish ground as well as the bowling ball material for the grip. Photo 6 shows the blade with the grip material fitted to the tang and the blade polished and ready to etch. As you read this this blade is etching. IF all goes well I should be able to pretty much finish this tomorrow save for the sheath. More as things progress..I still have to settle of a fitting style..I will ponder that this evening. JPH

-

Hello: First weld is by hand..I need the "feedback" so I know it is all sticking....after that it is about 50/50 hand and press work...

-

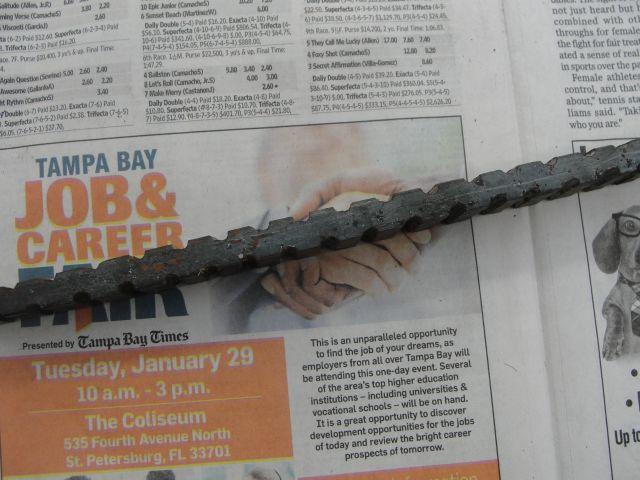

Howdy!! As I mentioned in a different discussion..here is how I do some pattern welding..This will be a "ladder" pattern something or other..haven't decided yet as to what exactly.. I will decide tomorrow once I am back out there...Have a couple if ideas so..in the words of "The Great One" Annnnd AWAY we GO!! The first photo is the raw materials..1095 sheet, 1070 sheet, some L-6 and some 300 series Stainless HT foil (that is he bright shiny stuff one down from the top..) There is a total of 80 pieces all together. Second photo is of the bunch stacked in my usual pattern and put together and wired, ready to weld .. Third photo is the first weld.. Fourth pic is the piece drawn out, cleaned and cut into thirds. Last photo is the second weld.. This gives me enough "laminations" to make a rather decent looking pattern once I get the rung grooves cut which I will do tomorrow. This is really the boring part..The fun starts in the AM with the patterning. So stay tuned for more excitement... JPH

-

Glen: OK Brother..let me get it going..and all i ask is AFTER I get the series completed..then you can put it where you think best,,I am thinking of starting it in this section..just to be consistent.. as they say.. Now this will take a bit of time as I am working it into my schedule... but I will be posting updates and SLTT as work goes progresses on this. Does this work?? FAB ---- JPH

-

OK done deal.. The only question is...where do I post it?? FAB-- JPH

-

Eutro: The benches are made of good old pine 2x's and plywood and then sealed/stainedwith Thompsons..nothing fancy just solid benches.. Frosty....the belts.. I order these by the gross..come to think of it I am starting to run low so I got to get more.. On different note...just putting this out there..is there any interest in a how an old man does a pattern welded something from starting sheet high carbon steels and hardenable stainless shim to a finished whatever it turns out to be...including the bovine ivory grip?? Let me know cause I need more stuff for my site.. The two fancy daggers above sold yesterday FAB- JPH

-

Eventless: I am three counties south of you in Pasco County.. in Spring Hill actually..Not all that far really... Bro Thos.. YOU are correct sir.... JPH

-

Eventless: Don't fret..everyone starts out naked and ignorant... Some decide to stay that way..others better themselves.. So just hang in there and keep chipping away at it..I have been doing this for a couple of years so..I do have a wee bit of a lead on ya but if I can do it as ham handed and as clumsy as I am... just about ANYONE can.. FAB.. JPH

-

Frosty: I live in a jungle..of course I got trees,along with vines..snakes..lizards..peafowl, opossums, squirrels, turtles an d those cute little gopher tortoises and a few gators and armadillos Horse: Well what you said is the way you see it.. I made them..that is true...but they were made in my front yard and I am well on the downhill side of 100 so... Brother Thos: Who you calling a"tool"?? heh heh heh pics of my front yard studio: FAB JPH

-

Howdy!! Here are a couple more by an old man working in his front yard... The smaller one has some pre-WWI Bakelite on the grip and a 12.45 Ct Star Sapphire in a wood grain pattern blade.. The larger one has some of that bowling ball material I scrounged a while back for the grip with a 27.8 ct Purple star Sapphire... Peppermint Twist pattern blade..all have bronze fittings.. Didn't come out too bad for an old man in the front yard.. FAB... JPH

-

Hello: Well I for one don't see a problem with the pattern at all...but then again..what do I know anyway?? I am just and old man working in his front yard...I don't see any bad welds or inclusions so...you done a really decent job on the steel.. FAB JPH

-

Hello: Here's some more new stuff that was done this last week...made by an old man in his front yard.. One piece worked..the others are what I call a "pattern fail"...The one that worked is that wavy "feather pattern" and I wasn't sure it would turn out OK but it did.... Now the others, while they are OK as far as knives go..are not what I was going for in this pattern..Oh well..as I said before...experience is what you get when you don't get what you want... Materials are 1095, L-6 and a small amount of meteoric iron.. Bovine ivory or exotic hardwood grips..all have phosphor bronze fittings.. Even with the failures..all in all the knives are OK I guess..all but one was a fail..Oh well.. At least that one came out as I wanted...sigh Hope these pics come out alright.. Well this old man needs to get back to work... JPH

-

Guards..no guards..all personal preference..There are a lot of knives out there with no guards and well..as long as they sell..I will make them and folks LOVE the little double edged bovine ivory gripped knives but just about everything I make sells out quick...that's why I try to make as many as I can in a batch so I can have something to put up on my site.. JPH

-

Hello: Here are the results of the last few day's out in the studio. All pattern welded using 1095, L-6 and some meteoric iron thrown in for giggles... Bovine ivory or hard wood grips...phosphor bronze fittings... Hope the photos turn out...Again..not too bad for an old man working in his front yard.. JPH

-

Thos: Yeah I have that genetic "defect" Mediterranean Thalassemia "B":.. AKA the Asia Minor version of sickle cell anemia...I haven't had any problems for a good while now so...I am not complaining.. well I am knocking off for the night...have another PW sword to finish as well as another 3 or so PW knives of various styles tomorrow ..so I need my beauty sleep... JPH

-

Hello: Just finished these a few moments ago.. All are PW in 1095/L-6 with a smatter of meteoric iron...Bovine Ivory of various flavours, Rosewood and red stag grips... Phosphor bronze fittings.. Didn't turn out half bad for an old farte like me working outta his front yard... As for book IV..since Paladin Press closed a year ago next month I had to scramble to find a new publisher, which I did..I need a graphic artist and a photographer..the book is 85% finished... I had some "away" time due to my work of the JJ Perret book we are doing.. JPH

-

Jcl: That is pretty much spelled out in my books... it's really not the "layer count" as much as it is contrast between the materials and how they are etched.. JPH

-

Here is some new stuff made down in our new studio in the jungle.. All are PW and have skeletal grip materials..mainly Bovine Ivory/... Hope these turn out

-

Hello: I has taken me a while to come to terms with this but Wayne Goddard passed on last week..I knew the man for 35 plus years at least..closer to 40 actually.. First AG now Wayne..seems that the folks I know from "way back" are passing over.. He was a great guy and quite the character.. JPH

-

Hello: Well after 7 months of down time I have just finished the first few from my first batch of blades made down in our new Florida studio..all are PW... 5 bovine ivory and 1 Red Deer antler. Didn't turn out too bad considering I am so out of practice.. Thought I would share..these go up on my website tonight. JPH

-

How do I harden old railroad spikes?

JPH replied to Turbo Dog's topic in Heat Treating, general discussion

just a twopence worth.. supersaturate brine...ICE cold...works ok...do an edge only quench and no need to draw if back....I do get a usable knife out of a RR spike but then again..I tend to be able to do a lot of stuff that most folks can't figure out how I manage it... I make my RR spikes a bit different from most others that make them...they are very quick to do..I figure I have about 12 to 14 minutes in each one JPH -

I have no idea..all I know is a good solid whack with a brass hammer trying to get a fitting tightened back up seemed to of done did it..it's running all well and good now so...I have no clue (not the first time that has been said) about what happened but I am not going to question it.. I am finally able to use the blasted thing so... JP (still cleaning up hydraulic fluid) H