-

Posts

119 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by G-son

-

There are several types of low silver content solder (or "solder"). There's the tin with a few percent silver in, that's a soft solder with a relatively low melting point and somewhat limited strength - higher temp than lead/tin, but still low temperature in the world of melting metals. There is also the phosphor-copper brazing rods for brazing copper pipes in plumbing, the phosphor content makes it "self-fluxing" on copper. Sometimes used w/o silver, sometimes a few percent silver is added to make it flow better into the joints.

-

I agree. Brazing gives so many possibilities, and particularly silver brazing (incorrectly a.k.a. silver soldering) is great. Anyone with a descent size hand held propane burner can silver braze things of limited size using high silver content brazing rods, bronze brazing has similarities and the lower price is nice, but the higher working temperature requires a bigger torch that can bring the metal up to more like orange heat. Still easily done with most DIY torches discussed in this part of IFI, but hard to do with the small store bought hand held torches. This burner was built almost exclusively by silver brazing (the mig tip was soft soldered in place, for easier removal if needed, everything else is 40% silver brazing rod). Not a pretty build, but most of it came out of a scrapheap...

-

Take a look at shipping containers. Four walls and a roof, sturdy construction, if you have lots of rain in your area you may want to add a sloped roof on top, nothing fancy needed. Also, once you don't need it anymore you can sell it, or move it if you need to.

-

Aluminum or even plastic tubing may be an option for long, light weight handles. Not very forging related, but sometimes you just need the best solution for the problem at hand.

-

Are you sure the jaw moves freely? Disassembly, cleaning and a little fresh grease can work wonders for things that are supposed to move but don't want to.

-

Well, people may read answers without replying to them, or even being logged on.

-

"I measured once, cut twice, and the XXXXXX thing is still too short!" Prototypes get extra length where practical, much easier to cut off excess later than adding more if it's too short.

-

If you use filler rod for TIG or oxygen/acetylene welding you don't have to deal with any flux.

-

We want the air and the gas to mix as good as possible, if I've understood correctly this is usually achieved with a rotating flow (a.k.a. swirl) or some other kind of turbulent flow through the mixing tube, correct? Is there such a thing as too much swirl? (I think someone has said there's no such thing in a naturally aspirated burner, but that implies there can be such a thing somewhere.) Has there been any known attempts using multiple gas jets in a burner to create/increase swirl? Say, for example, one gas jet in the conventional location, and one or more (possibly much smaller) jet placed at an angle somewhere in the burner to cause the air-gas mix to rotate as it goes down through the burner?

-

Thankyou, that's interesting.

-

Interesting. I'm thinking that the internal thread means you need to keep that mostly as is, you can't grind it down to reduce how much it affects the air flow past it. The type in the first picture would probably be fine no narrow down quite a bit. Not sure how much that would matter?

-

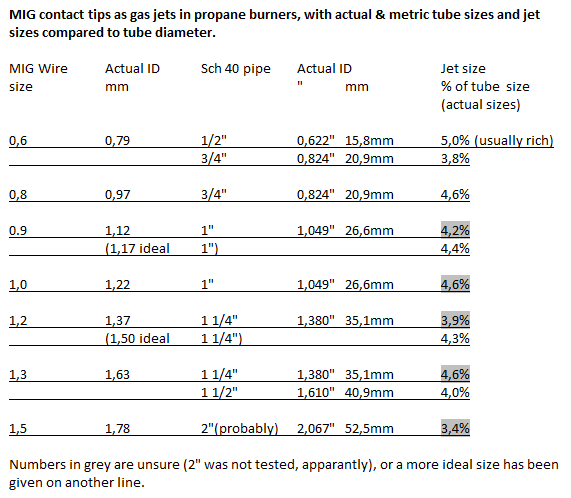

Okay, so the nozzles not ideal. If you do try them, please let us know how it works, while they probably aren't perfect they may be good enough for some of the times we don't need perfect. I have been looking a bit at glue dispensing tips, but I'm not happy with them being partly plastic with just a stainless tube. Might work, but I'm not sure I'd want plastic pieces in a burner. Cannibalizing the metal is an option, and removing the plastic. I put the data together mostly to get a better view over it all for myself, but I thought there may be more people here that find it useful. Also, if I put it here I know where to look for it next time I need it... Never miss an opportunity to tell people to think for themselves, too many of them don't. Nice to see you thought this deserved a thread of its own, not just a spot in burners 101. But perhaps a topic that describe the content a little better might be suitable? Something like "Gas jet size vs mix tube diameter, actual diameters" - something along those lines, not sure how long the topic can be here. The headline on the picture was mostly for the times the picture ends up somewhere else, without the rest of text, as a discussion topic leading to the picture something a bit more descriptive might help people know what it's about.

-

Which brings us to the topic "how short is too short?" (Keep your girlfriends out of this one.) Looking at the jets in store bought small burners the orifice seems to be quite short, a couple of millimeters at the most, and often there's a filter of sorts mashed down into the mouth of the jet too so there's no laminar flow into the orifice for sure. Not a perfect design by what we have learned around here, but it seems to work. With smaller diameters shorter orifices would seem to be acceptable, but how much is enough?

-

I took the liberty of making a list of Mikeys suggested MIG tip vs. pipe sizes, and added the actual pipe diameters (instead of the schedule 40 pipe sizes that aren't the real size) and the tip size in percent of the mix tube diameter. I thought it could be useful for people who build burners using other kinds of pipe or tubing, and the gas jet vs. mix tube size may be useful for people building other size burners than the listed ones - something in the ~4.0-4.6% range seems to be right for most of the listed sizes, possibly more on smaller burners and less on larger ones. I just gathered the numbers in one place, everyone gets to draw their own conclusions and use it as they see fit. The information was already out there, I just try to make it a bit easier to compare and use.

-

I just thought of using 3D printer nozzles as gas jets for small burners. I've just made a little research, but they seem to be available down to 0.2mm diameter. Not sure about the internal shape or length of the narrow passage, probably varies between different manufacturers. Do they seem suitable? Availability seems good, price okay (but not great, like the mig tips).

-

Trial by fire, the only way to test a burner. First real use of the burner was heat treating a new jaw for my old broken sheet metal shears, made it from a worn out file. Might still want to grind the jaw to a slightly different shape, but all in all, worked out great. Edit to resize huge photos.

-

Ah, good. Now I just wonder why this thread is a sticky, it doesn't seem to contain enough information to deserve the spot.

-

Since this is a sticky discussion with the title "burner to cubic inch relationship", wouldn't it make sense to have some general info about burner size vs. forge size in it? I kind of expected a nice and tidy list, or more than just a discussion about a single burner size at least.

-

New nozzle (still sheet metal for testing), about 1mm larger diameter and 2½* mix tube i.d. long (as suggested by Mikey in an earlier discussion). The improvised firebrick "forge" appears a bit brighter/hotter in the video than it actually was, but the video was taken a couple of minutes after lighting it. Gas supply won't let it run at max for more than a few minutes, still stuck with the small canisters. In open air, outdoors, on a somewhat windy day, the flame is hot enough to melt brass and turn steel bright orange. Heated & quenched a piece of spring steel, it hardened.

-

Number of burners, burner size? Forge size? (I'm assuming these factors should affect how much propane you burn.) What does the propane cost in your area? I did a bit of research recently and found out it makes a big difference what size tank you have. if I rememeber correctly, it cost ~$25 to fill a 2kg tank (not really an option for a forge), and ~$35 to fill a 11kg tank.

-

I'm guessing many members here have other ways to preheat cast iron items, either with propane, coal fire or something along those lines. Reduces both cracking problems and the amount of heat the welder has to supply. As for cast iron rods, Kastweld 111 may be another option. Another old trick is using old piston rings, they are made from good quality cast iron (some modern rings are not). Tried it with my Dillon (a.k.a. Cobra/Henrob/DHC 2000) welder, worked well.

-

The burner could handle quite a bit more gas (all I could supply) without going out since I moved the nozzle out about ½" (all photos/video are from after that move), so I intend to se what an even longer nozzle does. Increasing the diameter would be relatively easy and interesting too. Although I'm not sure what makes a nozzle "radical". Yeah, I know mild steel sheet metal won't last long there, but for quick and dirty prototypes it's nice. Once you know the size you really want it's worth putting a bit more work into something that lasts longer.

-

You mean the nozzle?

-

Looks like about $4/meter for the hose from the cheaper store chains, the copper brake line cost 3x that. But I guess I'd want more hose, so it would indeed end up most expensive.

-

I do want a large tank as it would be much better (and cheaper in the long run), and now that I know I've got a useable burner it's beginning to make sense to get one. For now I'll run it like this while I try different adjustments and modifications, and unless I've built more burners by the time I get a big tank & regulator I can just cut the copper tube and attach the hose to it. If I get a few more things I can build a small forge for it too, and from there the sky is the limit. Nice to hear that it looks good. Not bad for the first test of my first burner, with a build cost somewhere around $5. Half of that is the copper tube.