-

Posts

203 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by HEAP of JEEP

-

Show me your Bottle Openers!

HEAP of JEEP replied to Arbalist's topic in Blacksmithing, General Discussion

Had a couple of vacation days I had to use or lose, so took them to get some extra time to get stuff done for my upcoming show. Spent the morning on a couple of file knives. Then took the rest of the day and went a little opener heavy. Made a toasting fork/bottle opener. Then made one out of the end of a lug wrench. Then took the lug bolts out of a truck axle I scored at the scrap yard and made openers out of those. Took a few minutes to make one of those coiled rod candle holders. Then just because I've never gotten one that I like, I spent the last part of the afternoon trying a leaf key chain. This one actually looks like a leaf, so I'll take that as a win. Still long way to go, but my inventory is finally getting up there. -

Sorry, forgot to put in all the details. The blade is 5160 and 15n20 with a 1080 cutting edge. The guard is just mild steel. Started with some scrap 3/4 round and drew it out to its basic shape, but left it straight. Drilled and filed the hole for the tang, then after the handle was fitted, heated up the ends and bent them over a piece of round stock. Did the final clean up on it, then etched it in FCL for a few minutes to darken it up, then added some temper colors with a propane torch and finished it with some lacquer. The handle is some reclaimed walnut with a single brass pin.

-

As I've been forging up stuff for my upcoming craft show, I kept going back and working on this knife. So it felt like it took a lot longer than any other knife I've made, but total hours is probably about the same. I was trying to come up with something that looked cool and would draw attention to my table. Hope this does the job, cuz I don't think I have time to forge up another one if I'm going to get all my hooks and things done. Less than two weeks to go and I'm feeling pretty stressed.

-

That's great. I've been wanting to make one to show off the pendents I make at a craft show I have coming up, but I just hope I can come somewhere close to yours. My fear is I'll make something butt ugly to show off some otherwise decent pendents. At least I feel inspired now. lol

-

Am I serious? Um.... generally not...which usually ticks off my wife, but I do like monkeys...SQUIRREL!!!! Sorry, what was the question again?

-

I forged up another and ran video of it. Don't know if I showed everything, but it gives the general idea. Don't know the rules on posting video links, so I don't do it, but you can find it on my youtube channel under HoJ Forge or I can private message you the link.

-

Spent an afternoon doing up some more craft show projects. Since its my first one, and I have no idea what will sell, I find myself just doing up a whole bunch of different things. Maybe that's the best way for the first one? Anyways, took some inspiration from Chandler Dickinson on youtube and made up a bunch of viking rune pendents from some cable damascus and a herb chopper from an old file, snatched from the scrap yard.

-

Still trying to come up with some cool ideas for my first craft show in a couple of weeks. Played around with a spike last night. Saw this idea when I was googling spike ideas, and decided to give it shot. Took longer than I wanted but I think I can get them done quicker on future ones.

-

No, Sir. I cut the head off the spike and set it aside, then took the rest of the spike and flattened it. Drew it out a ways... don't remember the exact length... probably 8 inches or so, then cut that in half and used it as the outside layer of a laminated billet. Sort of like a san mai, but mine was 5 layers instead of 3. So it was, layer of spike, 15n20, 1080, 15n20, other layer of spike. Once the blade was shaped, I used a smaller spike to forge the guard, then fitted the walnut for the handle and welded some threaded rod on to the end of the tang, drilled and tapped the head of the spike to screw on, and used 5 minute epoxy when I put it all together. Hopefully that will keep the head of the spike from coming lose.

-

Questions about Selling at a young age.

HEAP of JEEP replied to jacbow2's topic in The Business Side of Blacksmithing

You've gotten some good advice on here, but as the father of some lazy bum teenagers, I'd like to weigh in... since my own kids have no ambition beyond the next video game. LOL First off, good for you for thinking about the business side of it at your age. My only word of caution, is find the balance at first, while you're learning. By that, I mean, find the balance where you still love to fire up the forge and move some steel around, just for the pure joy of it... but also have a part of your brain always working the numbers... how much time did this take? How much did it really cost me to make this item? Forge fuel and stock prices are important, but so is electricity, grinding wheels, and bandages. Get to know what your real costs are. As you gain in skill, your time commitment will get smaller, The bag of coal you bought yesterday for $10, might be $15 tomorrow, etc... so get to know the formula for figuring it out. Don't just figure it all out for an item, and for the rest of time, figure it will always be the same. But especially as your starting, you don't want to lose the "fun" aspect of smithing or it will become more and more of chore to fire up the forge, and at some point, you might find that becoming an accountant sounds a lot more exciting. When you do reach the point of supporting yourself/family with your smithing, then that's where work ethic should come in. When you have to pay the mortgage, and the only way to do that is by selling your wares, by then you should have a sense of duty... for now, though, especially as you're starting, don't lose the joy. Now here's what I think is the key for someone starting out and testing the waters. Learn how to sell yourself along with your product. When everything else is equal, people will buy from people they like. Example, if you're at a show and you and the guy next to you are both selling similar bottle openers for the same price, if you can engage the buyer, get them interested in your personal journey into blacksmithing, and show real interest in them, it might just get you the sale over the guy/gal that is only pushing product and couldn't care less about befriending a potential buyer. There's a bunch of great books on the subject, interpersonal communications and all, and just learning some basics about body language can really help. When a potential buyer walks up, greet them with a smile and openness and you will be miles ahead of the guy that just sits in his chair and looks like he couldn't be bothered with talking to people. One other key, especially when turning a hobby into a business, is learning to walk the line between profit and loss. In a business, you ideally want a certain amount of profit on each sale. In a hobby, motivations can vary, but for a lot of us, its just making enough to keep buying supplies and maybe get a little extra to take the wife and kids out to eat. Because of that, I have no problems dickering with people and haggling on price. I actually enjoy it, but its easy for me because my hobby doesn't pay the bills... it pays for itself, and that gives me a lot of leeway. From a purely business perspective, I lose a ton of money. From a purely hobby perspective, I'm doing better than I thought I ever would. I'm in the same boat as you, where I need to start looking at more of the business side of things, but I also know myself quite well, and know that when I do start taking the business part more seriously, I may lose the joy in just going out and moving some steel around, just to see what I can make. So I encourage you to find the line between profit and loss for yourself, and decide how close to that line you are willing to go. Are you willing to sell an item that, from the business side, should sell at $20, for as little as $15 if someone offers that? How about $10? In step one, you already figured out what the actual cost was, so you know you're break even price. How close to that, or even below that, are you willing to go to get a sale? Go below it to often, and you will need to find another job to support your hobby. Stay above it to rigidly, and you may lose potential sales as you're trying to grow your business. That's where talking to and getting to know your buyers is important. It becomes a lot easier to sell a $20 bottle opener to them for $10 when, by talking to them, you know they are also in the market for a set of custom fireplace tools that you could forge up for them... maybe you pad the price of the fireplace tools by $10 extra to make up for what you lost in the bottle opener, or maybe you even dicker on that price a little, but in the end you still come away with a nice profit. Either way, however you do it, you have to live with the decision, so make sure whatever decision you make, is one that you can be happy with. -

First off, very nice work. Second, congrats on reasoning out the perfect excuse to add more tools to your war chest. Third, now you've gone and done it! First comes the trellis, next it will be the wrought iron fence she wants all the way around your property... so much for any free time you thought you might have coming up. LOL

-

Very nice. My wife has been bugging me to make her of these. I've never tried one, but they sure look much more rugged than the ones we always get at the home stores.

-

Nice find on the Devil's Claw... That's its name now... and my selling point. The Devil's Claw seed pod will easily grab on to things, and doesn't like to let go... just like a good hand forged coat hook. LOL

-

Was playing around with some design ideas for different hooks and things, and this one sprung up from a piece of rebar I had lying around. Not sure if this style of hook has a name or not, but my wife said it sort of looks like devil's horns, so I'm going with that until I hear different.

-

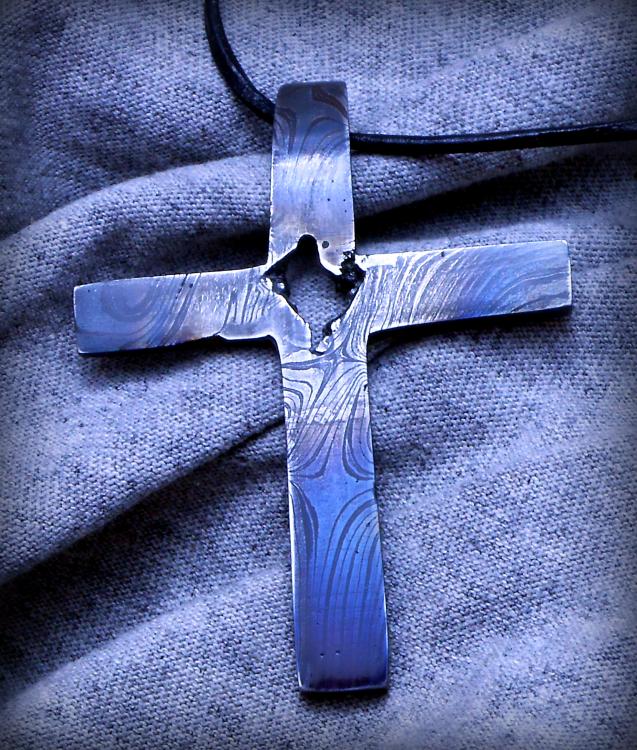

All great advice. I appreciate it all. In real life, I host an afternoon radio show on a classic rock station so I'm quite used to talking to people, but I've never been much of a salesman, so that part may be a bit challenging. I'm a showman... my job is to entertain and maybe get a laugh from time to time, so hopefully, my natural persona will suffice when it comes to selling my own wares. I like the idea of coming up with stories about the items... one thing I'm pretty good at is making stuff up... heck, I make a living doing that. lol. I decided that the hole in the damadcus cross resembles a country that I'm very familiar with... The People's Republic of Screw-up-istan.

-

In trying to come up with smaller items that I can knock out for my first craft show at the end of the month, I decided to try my first split cross. I went a little large, but it came out pretty good, and didn't take much time at all. So, feeling confident, I decided to see how difficult a damascus one would be. Got the billet forged up from scrap that I won't use for knives, and aimed to go quite a bit smaller than the first. I don't know if its because I was going so much smaller, or if I was just over confident, or a combination of both, but somehow I screwed up on cutting the slits, so the hole in the middle came out anything but square. I like the uniqueness, but it wasn't what I was shooting for. Finished it up after the etch by giving it some blue and purple temper colors and then sprayed it with a couple of coats of clear lacquer. Took longer than I wanted it to, but if I can get my time investment down, I think these will be winners at the craft show.

-

Taking the Jump... First Craft Fare Space

HEAP of JEEP replied to HEAP of JEEP's topic in The Business Side of Blacksmithing

Great ideas, everyone. And Frosty... yeah, the booth rental is five bucks. LOL. Cherry fest is going on now, but they charge way to much for a booth for a lowly beginner blacksmith. As for the other festivals, they are all about drinking... we have a ton of micro breweries, and we're big wine country up here, but they don't have crafters at any of them. The bottle openers and cork screws would still probably be huge though. Since this space is so cheap, even if I sell one lowly s hook, I'll have doubled my money, but figure it will be a good learning experience on a few fronts. I can see what kinds of things sell, but I will also get a sense of what I am able to turn out in a set amount of time, so I can maybe plan ahead for a few more shows next year. -

So, just wanted to thank everyone on Iforgeiron for all the encouragement since I started my blacksmithing journey. Because of the knowledge I have gained, plus a little pushing by some friends, I have booked a spot at the craft fair of our local county fair, and will be setting up my first display table to sell my wares. (For the amazingly low price of $5, I couldn't pass up the opportunity. lol) So, I've got three weeks to finish knocking out as much stuff as I can. Sounds like a lot of time, but when I think about it... just a couple of hours of forge time each night after work... its really not much time at all. Plus I've got two knife commissions to do during that time as well, so gonna be busy busting some stuff out, but wanted to come by and thank everyone on here for all of the great knowledge they have shared. This forum has been invaluable and I tip my hat to you all.

-

Beautiful work. Can only hope to achieve the same level some day. I'm awed.

-

Well, maybe its a towel rack.... not sure. Was working on some of those basic blacksmith skills that I seem t be lacking, while my wife was hosting a yard sale. A bunch of people came back to watch me forge and I met a bunch of people who have been wanting to learn. Met a great guy, an Iraq Combat Vet, with PTSD, and he's been wanting to try forging to see if that will help, so invited him by to pound some steel and I'll show him the little bit that I know. Managed to knock out this little rack while all of that was going on.

-

Yeah, I'll be skipping the actual step numbers in future videos... LOL Thankfully, I think the weirdness of the video matches the weirdness of the knife. Someday, maybe, after I get better at the craft, I may actually try and do some videos to actually help teach people... but that's step number 829, and I'm only on step 932.... wait a sec.... I take my Jeep videos very seriously, but in the few months I've been doing knife videos, my subscribers have doubled because of them, so maybe its time to actually put a little effort in to the forging videos too. I've actually got more subscribers for forging videos, now, than I do for Jeep repair videos, and I've been working on building the Jeep channel for years.. although I did really make an effort on the cable knife video and that one seems very popular. I just haven't been smithing all that long, so still don't really feel like I have much to offer in the way of teaching experience... The cable knives are the only ones that I've done a bunch of, so feel like I have a pretty good technique for them... everything else is always a "first".... I think I'm trying a dagger next... I'll probably run video... and since it will be my first one, I doubt the video will help much at all... I'll probably title it, "How to Forge a Damascus Dagger", but like most of my other forging videos, its just going to be an old fat guy, playing around at an anvil, hoping I don't screw up so bad that I have to start over... so very little actual "how-to" knowledge. Oh well... I'll keep forging, and as long as people are enjoying them, I'll keep throwing videos up about it. For me, its all about enjoying life, and trying not to take any of this to seriously... its gotta be fun, or I have better things to do. Forge on, my friend!

-

Somewhere around shabba-dabbo-do-million... LOL Its bad when you lose count on step number 3

-

Thank you, Steve. I'm tied up with work for the next little while with the Cherry Festival, but things calm down in the middle of July. Wife's going on vacation with the kids and her mother, and while she's out west, I'm taking a few days off work to just hang around the empty house, and hopefully get a lot of forge time... and weekends, as usual, I'm usually smacking some steel around. Oh, I think I just got another order for one of those damascus Thor's hammer, so was going to do up a billet big enough to play around with trying to make that heart for you too. I'd like to be able to nail that, and add it to my limited repertoire.

-

I really appreciate that, Dustin. Still really new to this whole thing... making good progress, but really enjoy it when people like my efforts. Thanks. I did make a video about this build. Its kind of long and much like this knife, its a little strange and goofy, but it does show the steps I took. I don't post the links, but as always, if anyone is interested, just send me a PM and I'll send you the link. Well... a railroad spike something. LOL. I really appreciate it, Frosty. Thanks.

-

They were recently working on the tracks in my town, and a bunch of the cut up track made its way to my scrap yard of choice, along with a bunch of spikes, so I grabbed a few the last time I stopped by. Decided I wanted to do a spike knife, but didn't want the spike haters telling me how bad of a blade it was, so decided to go san mai and put a core of 1080 and 15n20 in it. In the bottom of the bucket of spikes, were a couple of smaller ones... wasn't sure what to do with them, so decided to use one as the guard. I was just trying to do something goofy and fun, and this is the end result. Now back to the damascus.