-

Posts

19,305 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by JHCC

-

It is. Now I feel sheepish.... It is indeed Nash, and the original third line was "It makes the peas taste funny"; see this article.

-

This lamb would be a good meal for an anemic: it's high in iron.

-

After abortive attempts at overthinking, we settle on a nice rivet forge

JHCC replied to JHCC's topic in Solid Fuel Forges

Took the shield off this morning to look at alternative placements (and to roll the raw edge). Should I be worried that it appears to be galvanized? -

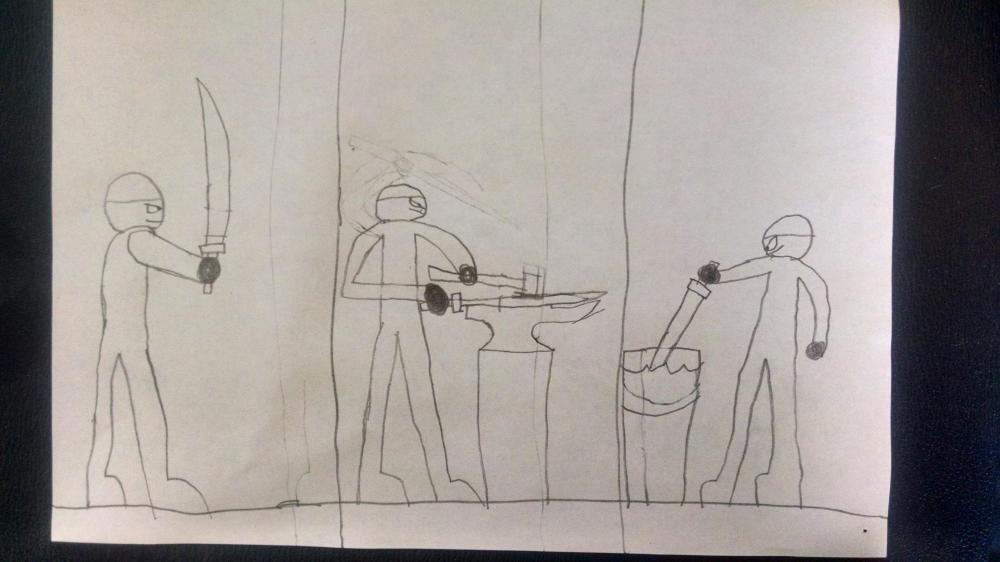

Hey, I didn't say I had time! However, here is an in-progress photo of a small hot-cut hardie that we're making from an old jackhammer bit. Should be big enough to cut truck axle for a properly sized one.

-

I've just been restarting my blacksmithing hobby after a twenty-some year hiatus. The one that got away? Except for two hammers and my anvil (which I've been lugging from apartment to apartment to the great distress of my wife; just couldn't let it go), my old forge and all my old tools -- hammers, chisels, punches,hardies, post vise, salvaged wrought iron stock from my neighbor's old farm in Vermont, etc, etc, etc. Left it all behind when I moved to the city. There was this one six pound (or thereabouts) sledge that I would use one-handed for stock reduction, which I now realize was essentially a double-ended rounding hammer --really missing that one right now. On the other hand, this very morning, I found a lovely crescent of broken coil spring on my street while I was out walking the dogs. It got me thinking: I've got my anvil, a couple of hammers, a decent little rivet forge, some vice grips, access to scrap tool steel (courtesy of the shop that takes care of my van and my wife's car), a few other tools that have come my way, and an enthusiastic (if unskilled) striker in the form of my twelve-year-old son. I've got my old skills (rusty and limited though they be), my brain, and resources like my old books and IFI. I have everything I need to find, buy, or make everything I want.

-

I just got these from an antique store in Maryland. They were somewhat more than I would have liked to spend (~$34), but with the 2" opening, I figured that they'll be useful for forging anvil tools. Good, solid bits of iron. (There were a couple more pairs at the store that probably would have beenbeen more useful day-to-day, but at practically the same price.)

-

It was foul, whatever it was.

-

After abortive attempts at overthinking, we settle on a nice rivet forge

JHCC replied to JHCC's topic in Solid Fuel Forges

Saint Clement and Saint Dunstan, pray for us! I don't I think I want to rotate the ducks nest a full 90 degrees, as longer stock would then interfere with the lever for the blower. After I get back from vacation, I'll take a look at rotating it may be 45 degrees clockwise and shifting the attached shield a little bit counterclockwise. -

Not Portland cement -- it will degrade and spall at forging temperatures.

-

After abortive attempts at overthinking, we settle on a nice rivet forge

JHCC replied to JHCC's topic in Solid Fuel Forges

One of the quirks of this particular forge is that the blower runs very smoothly at low speed, but if you crank it too hard, it starts rattling like a possessed thing. Perfect for charcoal. -

If your soil is like mine, you've probably got a layer of topsoil that's a mixture of clay, silt or sand, and organic material, over a subsoil that's more pure clay. Go for the pure clay subsoil if you have it.

-

After abortive attempts at overthinking, we settle on a nice rivet forge

JHCC replied to JHCC's topic in Solid Fuel Forges

Entirely agree about the thickness of the duck's nest. Another advantage of where I live in Ohio is that our soil is heavy clay, so materials won't be a problem. -

What a coincidence; I just got one of these yesterday, too!

-

After a couple of abortive attempts to make a coffee can gas forge and a charcoal bucket forge, I decided to make a Tim Lively-style washbasin charcoal forge. Stopping at a local antique/junk shop to see if they had any old washbasins, I was rather surprised to find an old rivet forge that they had recently bought from a local farmer. It had apparently been buried under a pile of junk; judging from the combination of rat's nest and nameless filth (smelling suspiciously like raw sewage) that was clogging the blower, I can well believe it. The leather belt was not in great shape and snapped when I was looking at it in the store. $125 as-is. Since I’m burning charcoal, I made up a deeper firebox with ash and some fragments of adobe from one of the earlier forges. I made a new belt out of some nylon webbing I had lying around. And here we are, ready to go. On the first firing, it did a good job of heating both some 3/8” round mild steel and a smaller-size jackhammer bit that I’m turning into a small hot-cut hardie. I will definitely be redoing the firebox, to make something more Lively-like, both to be more durable (since I have to move the forge in, out of, and around the garage) and to hold the fire at the right size and the right place.

-

I met my wife in 8th grade and started blacksmithing in 10th grade. This is the decorative fork I made for her for her Sweet Sixteen, just over 30 years ago.

-

You want me to live, right? Ain't no way I could get away with that! (Although, if you add up how much we've spent on my wife's china collection....)

-

I've got it pretty well cleaned up and ready to go. I don't know what the heck had collected inside the blower, but it looked and smelled like raw sewage. Fashioned a belt (at least temporarily) from a piece of strapping I had hanging around, and built up a charcoal-type firebox from rubble, ash, and the adobe top of the bucket forge. Here's hoping!

-

Okay, the universe has come back to spank me for talking trash about being cheap. I stopped at a local antique shop to see if they had a cheap washtub for a Tim Lively-type forge, and wouldn't you know that they had practically the twin of my old farm forge. A quick phone conference with the wife about the possibility of putting it on a credit card (given that we're trying not to add to the overall debt), and it's mine. Things were helped by the fact that apparently my daughter also wants to learn to blacksmith, not just my son.

-

Actually, all this is moot, since I happened across an old farm forge at an antique shop that I was able to convince my wife to squeeze into the budget. And yeah, I know I was saying before that I didn't have any room in the budget at all. Sometimes, you just have to bite the bullet and go a little crazy. Now, was $125 a good price for this? It needs a new drive belt, and the ash door is a little rusty, but otherwise, everything appears to be solid and moving well (once is cleaned the rat's nest from the blower, that is).

-

Unfortunately, it looks like the forum software has lost the photos that used to be on this post. Would you all be so kind as to help a newbie out and repost them? Many thanks!

-

I think I'm going to go with a Lively forge, once I can scrape together a few bucks for the washtub (unless I find one at a yard sale for cheap). I've already got a couple of lengths of black pipe I can use, although the one that's long enough isn't threaded for an end cap and the one that's threaded for an end cap isn't long enough. Maybe I have a friend with a pipe threader....

-

A lot of it flaked off already when I was bashing the bucket into shape, but the chicken wire and clay suggestion is a good one.

-

-

Since his site is down, here's the WayBack version: https://web.archive.org/web/20140829131114/http://www.timlively.com/washtubforge.htm