Brian Evans

Members-

Posts

75 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Maine, near Brunswick

Recent Profile Visitors

1,484 profile views

-

It turned out that I didn't have any problems with clinkers was because they were collecting along the sides of the fire pot in a somewhat solid form. My best guess as to why I didn't notice was because of the soil I used as fill for the forge. It has a high organic composition and was burning away at a slow rate being replaced with clinkers. I recently had to take it all apart because the fire pot got too small and that is when I discovered what happened. I apologise for any misguided attempts at making a clinkerless fire.

-

Not completely, I use small pieces of coke and anthracite to refill the fire pot. However the fire cave lining still burns just not as quickly. I will take pictures of it before I fire it up to help explain it better. I know I'm not doing the best job of it. I typically use rice coal anthricite and bits of coke leftover from previous fires when I put it in the fire pit. This is what my forge looks like.

-

I was curious to see if any else used a combination of anthracite and bitluminus coal. I like how I can control the fire when using both kinds (build a fire cave and keep the fire pot stoked). I have noticed that since using both kinds I have had no problem with clinkers and ash I'm not sure what happens to them but they don't build up in the forge. Maybe I'm doing something "wrong"

-

Yeah, safety should be the number I priority. I think I'll have to wait and save my money to either buy a welder and take some classes or buy a commercially made press. Thanks guys, I hope I didn't sound like too much of a fool for posting this design.

-

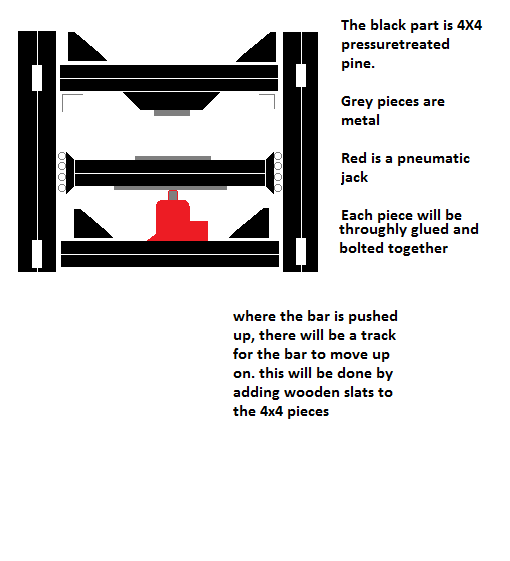

4 inch diameter (ish) of high carbon steel is what I have currently. I am not sure about the speed of the pneumatic jack but I would assume it would have to do with the air compressor psi which is 150. Are you trying to say that wood is useless in this application? I am not sure about exact number for the failure mode of wood but it has to do with the number of knots in the wood. I was planning on making sure that I didn't use wood that was too knotty. I have been considering buying a press new (as I cannot find any within driving distance used), but I don't really have 400$ to drop at the moment. If you don't think that making it out of wood is a good or safe idea then I guess ill have to sell a lot more hooks and bottle openers.

-

I wanted to be able to upset some of the larger pieces of metal that I have into a more workable billet. Also would like to try my hand at pattern welding. I would be using a pneumatic bottle jack so it should be quick and hands free as far as controlling the press (foot pedal). As far as making it with wood it is what I have available at the moment. I don't have any beams or frames.

-

First off I am prepared to get a lot of negative feedback on this design as it is to be made out of wood mostly. Safety is the number 1 concern and I don't want to jump into anything I am not prepared for. I am planning on using a 10 ton pneumatic bottle jack as the power. From my research to the tensile strength of 4x4 pine ( I was not able to find much) told me that a 6 ft long piece has a constant load bearing of just under 1000 lbs when hung from the middle. This design is estimated to be 3 foot wide by 5 ft tall, and there is supposed to be an even distribution of pressure along the beams. Any input is appreciated.

-

I have not, I haven't attempted to color things yet aside from quenching in linseed oil. This is what the guy asked for and he is happy with them. I have no experience pricing things where should I go to figure that out. (for future items, I already have a set price on these)

-

-

looking for trenton 258 information

Brian Evans replied to Brian Evans's topic in Anvils, Swage Blocks, and Mandrels

I'm not sure what ILL is but they didn't have it, I checked the whole system for the state and there wasn't any. -

After looking at videos and posts I think I am going to use a slitter and make the hole that way.

-

looking for trenton 258 information

Brian Evans replied to Brian Evans's topic in Anvils, Swage Blocks, and Mandrels

I have, but like you said the price is too high. I just realized that I hadn't thought to check the library. I think I will do that today. -

looking for trenton 258 information

Brian Evans replied to Brian Evans's topic in Anvils, Swage Blocks, and Mandrels

Maybe who made it. But with no serial number I wouldn't expect it to be possible. When were Trenton's first started to be made? Any information is nice, anvils are pieces of history. -

I was at a friends forge and he had a cast iron mandrel and it was hollow inside. The wood might fit inside a similar type mandrel. Im not sure I don't know much about mandrels.