-

Posts

274 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by angiolino

-

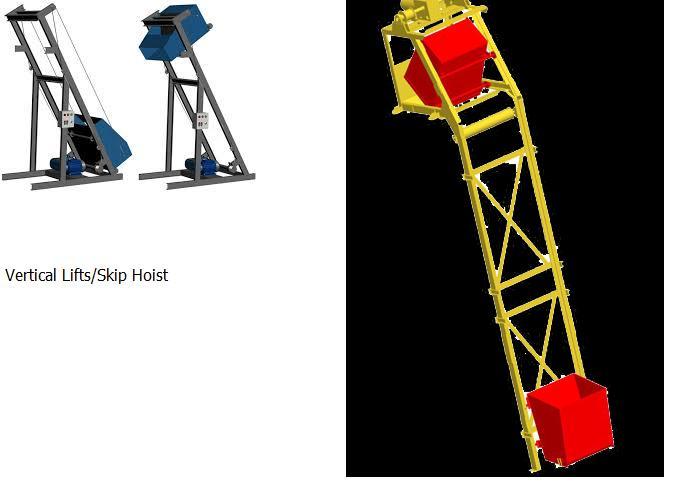

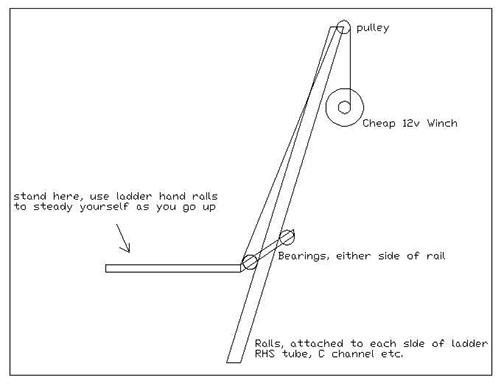

For a land in the countryside with terracing we will have to build a device for transport and lift type cableway. A friend of mine suggested to me like a monorails or a shingle lift or a ladder hoist type like those for construction sites as it is very short the path to be done from the cart about 8 meters. The weight to translate I think 500 kg. What can you suggest. Thanks to those who want to help me providing valuable suggestions, rail hoist frame in steel beam Rails are two 2x4s fixed together to form a L shape.

-

hinge? pintle? pivot? trust bearing ? I can not find the right pieces for the rotating turntable boom turntable support, I do not find the right bearing for the bolt pin, I believe I have to build modified piece on the lathe, do you have any suggestions? I thought it was enough to cut the drill bit and screw it, instead I have to build a hinge on the lathe, advice? thank you https://www.canadiancustomelectrical.com/shop/product/jib-crane-hinge-kit-426?category=57 https://www.materialflow.com/p/Wall-Mounted-Jib-Cranes http://www.westernsafety.com/products/spancocranes/spancocranepg6.html http://www.proservcrane.com/Products/AbellHoweJib https://www.pinterest.co.uk/pin/396035360957271480/ http://racingcars.co/wall-mounted-jib-crane/wall-mounted-jib-crane-stunning-types-accent-sales-and-service-co-home-design-ideas-29/

-

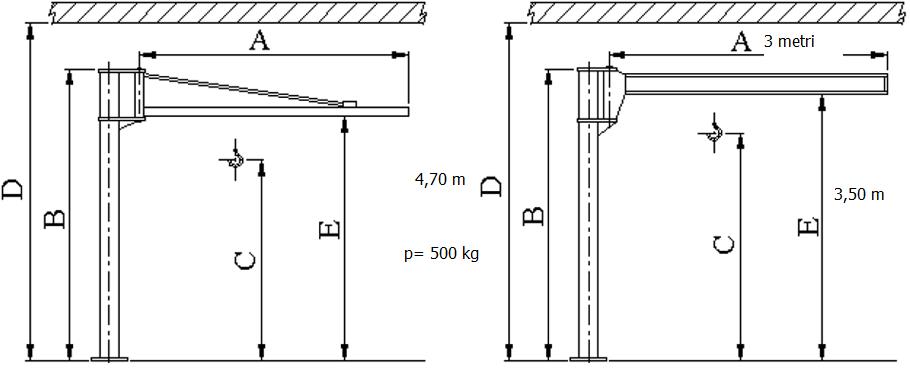

you say that I can build the boom without bearing thrust pads how? actually the bolts and the tie rods I found them I have difficulty in finding the bearings to make the boom swivel you have alternative solutions, if you would give me the courtesy to send me photos, as a boom beam I chose a ipe of 120, as a hea pillar of 100 high 4 matri I hope they are sufficient for a range of 500 kg, if it were a useful capacity higher sincerely bought a crane approved to be safe, anyway thank you again excuse me for the trouble I gave you the next http://www.oppo.it/tabelle/profilati_ipe.htm http://www.oppo.it/tabelle/profilati_hea.htm http://www.oppo.it/calcoli/travi/trave_acd.php pivot shaft swing boom hoist http://www.fsindustries.com/more_info/mast_type_jib_cranes/1_2_ton_capacity.shtml

-

I thank you for your intervention, I have to be honest, I was going to buy the iron to make the structure, then I stopped I had a conscience of conscience, if you give the zipper I'm afraid you hurt some one if not you I ask too much could you make me the photo of the support of the pin where the column crosses the pillar thanks, I was taking a 100 mm beam for the column and a Ipe 120 mm long 3.70 meters for the crossbar the hoist and the cart I have them already taken, I have to establish the bolts for the pins / creme 26 mm thick) and the tie rods to hook the upright column to the pillar (crd 20 mm in diameter to 60 cm in length) thanks again for your valuable intervention sorry all if I'm getting bored with this discussion thanks to the next I hope soon.

-

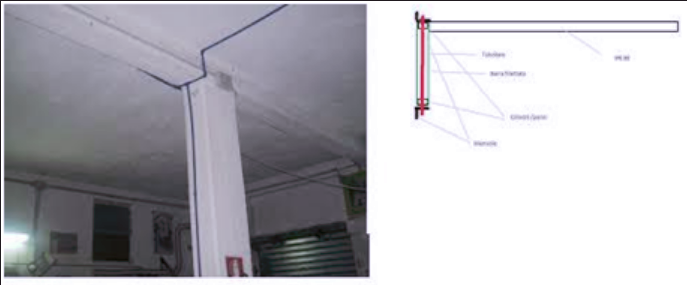

La struttura è stata progettata per resistere a una struttura più robusta e robusta a prova di indebolire la colonna dell'edificio, la gru riposa l'equilibrio alla trave d'acciaio, la trave in acciaio il saffo alla colonna in cemento armato attraverso staffe e grosse barre d'acciaio, devo trovare i vari materiali, sto lavorando grazie The structure was designed to withstand a more robust and robust structure to weaken the column of the building, the crane rests the balance to the steel beam, the steel beam the saffo to the reinforced concrete column through brackets and big steel bars, I have to find the various materials, I'm working thanks Swing arm hoist boom

-

http://www.practicalmachinist.com/vb/general/picking-up-heavy-things-machine-tools-when-your-old-324187/index2.html thanks for the right advice, my problem is not the welding but the rotating support of the hinge, if I do not realize it robust, when I load the crane gives and I beheaded the head, if you could give me pictures drawings measures would you do me big favor, even of the diagonal tie sorry if I disturb you and take advantage of your patience, but the security above all, the scope is modest, but the arm weighs 40 kg, the cart and the hoist 20, kg plus the weight to be lifted, if the zipper yields and falls from 3 meters high we hurt ourselves thanks again sorry if I bothered you again thanks again

-

http://www.ets-spa.com/it/ thank you guys for your valuable intervention, if possible I would like to have photos and drawings your Jib crane, for the pins I thought big bolts, but I also have to realize the supports and thrust ball bearings, I have to see if there are bushings in bronze "bronzine", a guy engineer tells me that a beam ipe 120 mm Ah H can support peak load maximum profit of% == 5 Kg 5 quinals, enough for me, the supporting column I want to do in steel leaning and anchored au a big concrete pillar of the building, my engineer friend suggested me to use a H-shaped steel beam with a 100 mm wide section HE as a vertical column, as a diagonal rod to empirically suggest to weld a 50x 100 mm plate thick what you think is safe is feasible. the structure is cantilevered like a shelf, I would not want to give up the hinges and beheaded, when I use the crane and I have a load hanging anyway thanks again, if you had other suggestions I invite you asottoporli to my attention thanks again greetings thank you guys for your valuable intervention, if possible I would like to have photos and drawings your Jib crane, for the pins I thought big bolts, but I also have to realize the supports and thrust ball bearings, I have to see if there are bushings in bronze "bronzine", a guy engineer tells me that a beam ipe 120 mm Ah H can support peak load maximum profit of% == 5 Kg 5 quinals, enough for me, the supporting column I want to do in steel leaning and anchored au a big concrete pillar of the building, my engineer friend suggested me to use a H-shaped steel beam with a 100 mm wide section HE as a vertical column, as a diagonal rod to empirically suggest to weld a 50x 100 mm plate thick what you think is safe is feasible. the structure is cantilevered like a shelf, I would not want to give up the hinges and beheaded, when I use the crane and I have a load hanging anyway thanks again, if you had other suggestions I invite you asottoporli to my attention thanks again greetings

-

Thank you for your intervention and your opinion, if I can afford to ask, how would you have done it? thanks again for your constructive criticism and your considerations

-

-

a friend user has created this jib crane that I found on the web made everything in steel beams

-

thanks for the precious suggestion, if maybe some friend user could attach some photos or drawings, maybe I could use them to get inspiration in the construction of my jib crane hoyst, thanks again sorry if I took advantage of your time and your patience

-

you would have the mathematical formulas or calculations, my would like to bracket it on a reinforced concrete pillar of the building measuring 55 cm x 55 cm is armed with iron inside the concrete, for the hinges of rotation what you advise me, how you built them I'm sorry if I take advantage of your experience thanks you would have other photos or drawings with measures to take inspiration, I'm sorry if I make you waste precious time and patience thanks again for the attention to the next

-

help construction planning jib crane hoyst for workshop

angiolino replied to angiolino's topic in Building, Designing a Shop

I have to build a jib crane hoyst, internal use workshop you could help me thank you, sorry if I was unclear http://racingcars.co/wall-mounted-jib-crane/wall-mounted-jib-crane-shock-cranes-spanco-home-design-ideas-0/ -

I have to build a similar one, you could give me some suggestions I have to use as a service crane for my lathe you could attach project with necessary measurements and materials, I have to realize the rotation ring do not know how to build it how to make hinges and hinges i gangheri

-

Virtual Assistant for project gantry crane 2 tons

angiolino replied to angiolino's topic in Welding/Fab General Discussion

-

ciao dovrei fare un laboratorio di gru a braccio, abbiamo bisogno di sollevare parti metalliche per lavorare su un grande tornio parallelo, le misure sono braccio di braccio di 3 metri di lunghezza, altezza sotto gancio, 3,40 metri, la stanza è alta 3 metri e 70 cm, non so se fare tutto in acciaio tra cui il montante del pilastro o per sostenere il braccio a una colonna verticale con una sezione quadrata di una sezione di pilastro in cemento armato 50x 50 cm, per evitare di costruire il basamento di fondazione che dovrebbe essere a mio parere 1 , 50, 1,50 metri di cemento armato, la gru dovrebbe sollevare fino a 500 kg, non so come rendere la cerniera / giradischi con supporto, per ruotare il braccio, avresti suggerimenti grazie, quale materiale usi quella sezione? grazie per la tua attenzione al prossimo

-

Hello, i would like to build a gym power rack using scaffolding tubes or acrow props, you would have tips thank you

-

superimpose various plates, it seems a good idea if you have other ideas or suggestions I invite you to sottopormeli thanks again, maybe drawings or illustrative photographs thanks again https://i.imgur.com/FPtrt.jpg https://i70.photobucket.com/albums/i98/buddknives1/anvil2.jpg https://meriwethercycles.files.wordpress.com/2012/07/baseplate-jman.jpg http://gilblog.com/anvil.jpg https://mikescustomweaponry.files.wordpress.com/2014/04/20140426-202840.jpg?w=440

-

Temporarily use a sheet metal plate big iron, if I can find a used anvil, I also find the condiziioni moving and shipping, someone accidentally built the blacksmith's tongs,. I use pliers to parrot as remedied? thanks for valuable suggestions, or old railroad iron, rails, beams or plates or junkyard mechanic, I'll see if I can find a suitable piece of heavy metal massive recovery thanks again Mod Note: Copyrighted image removed.

-

thanks for the right specific suggestion that I should not use the anvil blacksmith for work but rather by smith forging the tip of a chisel, shaping the nail of a lever to pry, cold straightening shape by hammering metal bars etc. thanks the idea, however, if others variants I invite you to sottopormeli thanks again to the next compared ideas and sugggerimenti thanks

-

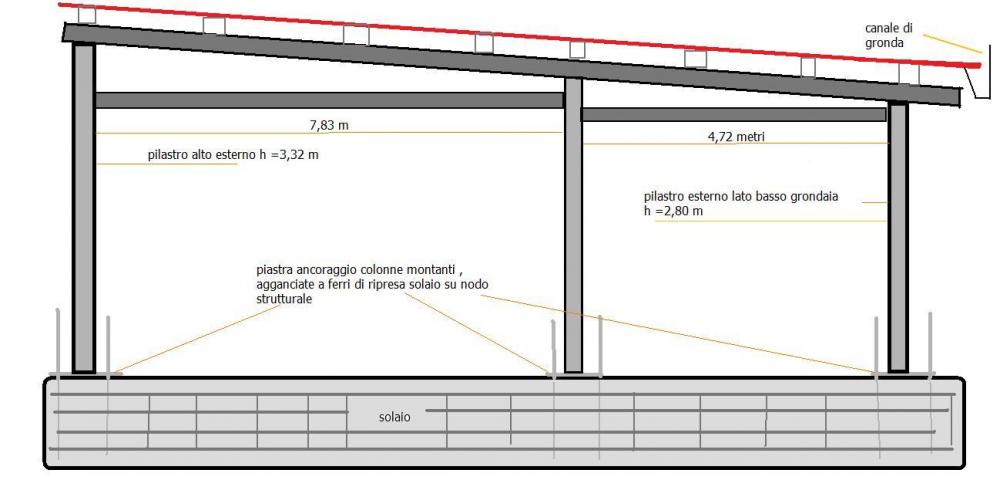

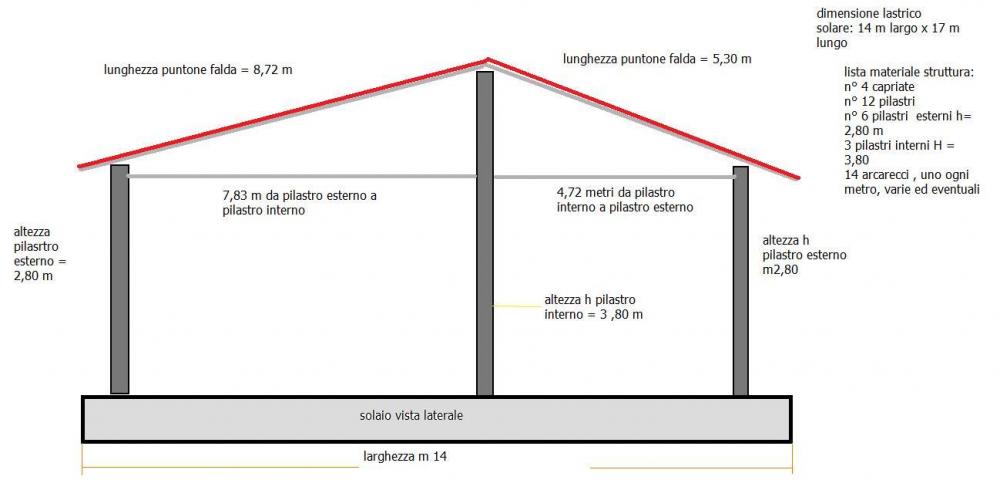

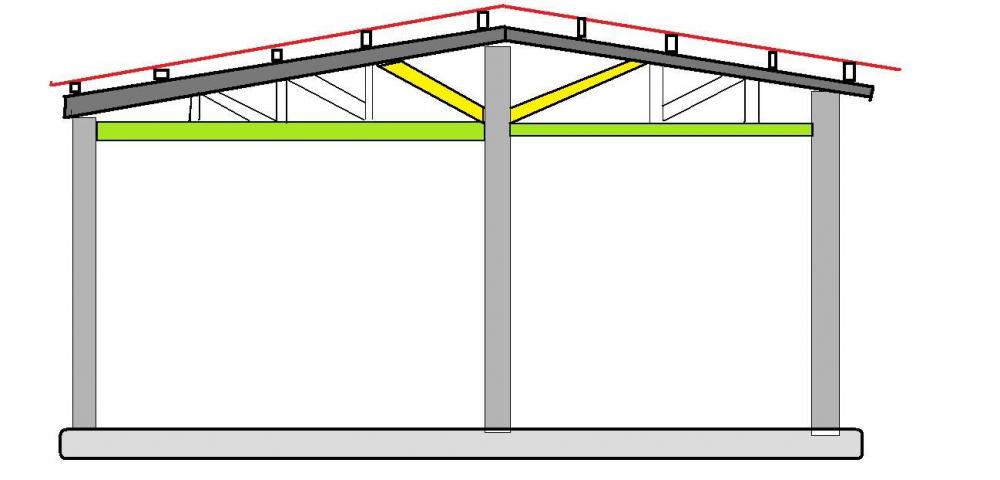

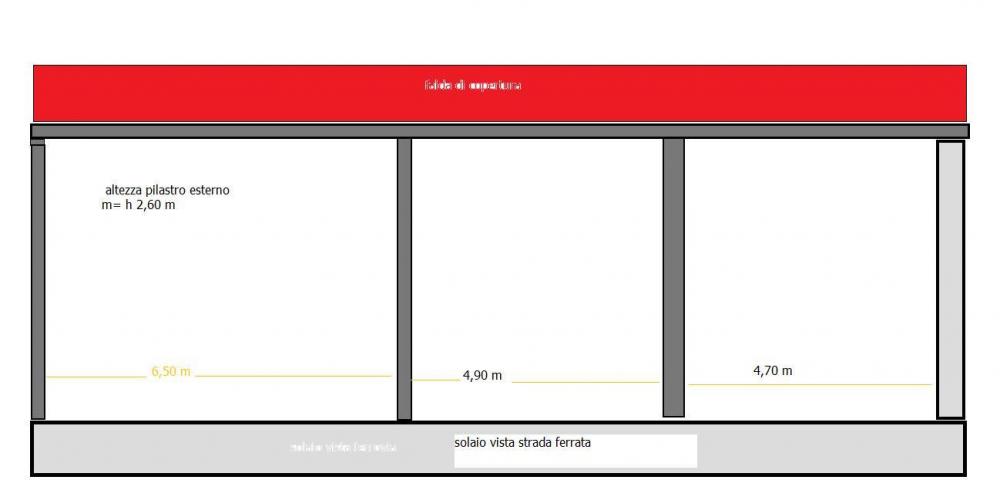

hello, I know I should appeal to a technical, engineer, architect, surveyor or structural engineer or higher, but I should make a cost estimate what you think? http://www.cad3d.it/forum1/attachment.php?attachmentid=44416&d=1467874497&thumb=1 http://www.cad3d.it/forum1/attachment.php?attachmentid=44416&d=1467874497&thumb=1 http://www.cad3d.it/forum1/attachment.php?attachmentid=44418&d=1467874954&thumb=1 ho anche fatto i conti della massaio, in linea di massima se manca qualche cosa ti invito a sottolinearmeloElenco materiali:1) N°6 pilastri esterni h= 2,80+ 3 pilastri interni 3,80 hea 1206x2,80= 16,8 m 3,80x3 =11,4 mTotale 11,4+16,8 = 28,2 metri x 19,9= 561kg pesoCapriata:14,02x n° 4 = 56 metri ipe 12056x10,04 kg/m= 582,4 kgArcherecci correnti = sezione 50x30x 1,5 mm17 m x 14 pezzi = 238 metri238x 4,27kg/m= 1016,26 kgCatene di controspinta14 metri x 4 pezzi= 48,4 metriProfilato ad U 100x50 = 10,6 kg m48,4x10,6 kg /m =513,04 kgTotale kg=2672,88 kg I also did the accounts of the steward, in principle, it lacks something I encourage you to sottolinearmelo Materials List: 1) # 6 external pillars h = 3 2,80+ inner pillars 120 3.80 hea 6x2,80 = 16.8 m 3,80x3 = 11.4 m Total 11.4 + 16.8 = 28.2 meters x 19.9 = 561kg weight truss: 14,02x No. 4 = 56 meters ipe 120 56x10,04 kg / m = 582.4 kg current Archerecci section = 50x30x 1.5 mm 17 m x 14 pieces = 238 meters 238x 4,27kg / m = 1016.26 kg Chains of counterforce 14 meters x 4 pieces = 48.4 meters U section 100x50 = 10.6 kg m 48,4x10,6 kg / m = 513.04 kg Total kg = 2672.88 kg what do you think, how you costruireste empirically, what do you think, where I went wrong thanks for your attention and technical advice http://www.cad3d.it/forum1/attachment.php?attachmentid=44432&d=1467907582

-

would you have photos or drawings with measures to take cues, like human ingenuity like the items recovered and reused for other purposes, is a form of art, do not you recycle repurpose reuse in these times of crisis in my opinion is a great resource, you do not find, pieces of tanks in my area and find none, perhaps pieces of trucks or earth moving machinery moo i can try thanks again for next allla tips

-

the workshop was the origin of his grandfather, he inherited all glia gear my cousin, who gave them away for a plate of beans, a pittance, I use an iron plate cutout big heavy a plate resting on two sawhorses in iron, but it is not heat-treated steel, with a hammer I can beat with heavy mace is not effective and efficiene, so I try anvil or similar tool, thanks for clarification would have other suggestions?