-

Posts

60 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by seagiant

-

Hi, Nice Vise, the good news is that the rear screw piece knob is not busted off! A LOT of Vises had that destroyed from people trying to use it as a swag post! The Leg and Screw Rod can be made easy enough. She just needs some TLC!

-

Should I get rid of my old Lincoln welder?

seagiant replied to rdennett's topic in Welding Equipment

Hi, As long as you have stick capability you are fine, but... I learned the hard way when I sold a Lincoln to buy a Mig thinking I was set... Found out real quickly I had messed up as the Stick Welder can use stick for Cast Iron, Steel, Stainless, ect. The Mig was great for thin to medium steel, but... Found a deal on a Miller 250 and grabbed it! Lesson learned! -

Hi, Thank you, just what I was looking for, all good suggestions! This is not a Chefs Knife but more a Kitchen Utility Knife, (maybe little difference on that, admittedly?) A LOT of little things to work on and your suggestion help! Still working on the handle part! Thanks again!

-

Hi, Wow, 80 views and not one comment??? This HAS to be the place for feed back! Thanks Boys and Girls!! One xxxx of a Forum you have here!

-

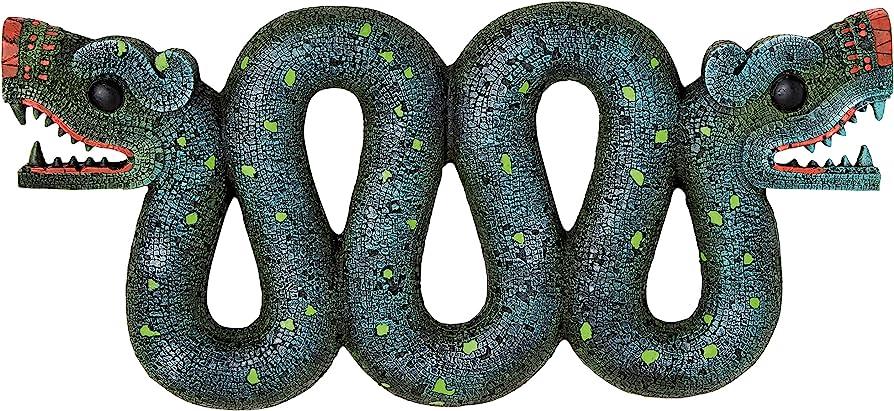

Hi, Got my Maker's Mark, from a young Lady in the Ukraine through Etsy... Do not see alot on Maker's Marks, but like to mark my knives. I think it also increases value for the future Owner and shows a Bench Made Knife. It's for Sea Giant Forge, and is actually, Quetzalcoatl, a Mayan, Aztec God. The Story goes that Quetzalcoatl, sailed away to the East and vowed to one day come back to claim his Kingdom from the Aztec. When Cortez arrived on a "Moving Island", from the East, the Natives was wondering at first if it was Quetzalcoatl, returning to take back his land??? (maybe it was, they lost their Empire!) Interesting if you like History, but think it makes a good Mark, with a story behind it!

-

Hi, Huh...Well...She'll burn some Propane!

-

Hi, Interested in your opinion, once you get it running!

-

Hi, Thought I would show my HT Oven made from a Toaster Oven... Opened the casing up and direct wired the Elements and added some K-Wool around the casing on 3 sides. Put in the Thermocouple and a firebrick to even the heat and she works pretty nice. Keeps a pretty even heat with no more than a 10 degree swing from what I can see. I also use this PID for my Cast Bullet Furnace and my Gun Kote Oven!

-

Hi, Thought I would put this up a Commercial Made SS Burner for $25! Made a Mini Mongo, but did not like it, saw this and was amazed at the price! Just used it and is pretty neat, you can adjust the needle valve and Air Choke to get a neutral flame or heat. Goosneck is threaded 1/8" NPT so any needle valve can be used.

-

What's your latest blade look like? Post em and let us see.

seagiant replied to HondoWalker's topic in Knife Making

-

Hi, Built a new Propane Forge to get back into making a few knives. This was made from an old Johnsons File. Thermo Cycled 3 times to refine the grain. My idea of a Kitchen Knife, farm cut Red Oak scales and Loveless Bolts for handles.

-

-

Hi, Curious about all the talk on Disc Grinders, threw this together from things laying around the shop, and... Might have fallen in love! Nothing fancy like the upper end high power VFD Contolled switch rotation, but... Has given me a bit of knowledge and will probably upgrade soon. Here's a pic and would advise anyone to give them a try, I was amazed how nice even this one works!

-

Hi, Thank you very much! Good things to keep in mind!

-

Hi, Sorry, I'm trying to get info on upgrading my old Bader to a 3 ph motor to give adjustable speed. The Bader BM-2 has a Baldor 145 TC Motor. The Motor I'm looking at has a 56C Frame, thought I was clear on that, but... So, if the new motor shaft is correct and has a "C" bolt face, I should be good. Might call Bader, just to see what they think? There should be tons of these old grinders still around, but see little on them or any upgrades? Thanks! Hi, Thank you, from the chart seems the shaft on the 56C is smaller (5/8") but... Better than larger, making an adapter is doable for me as I have a lathe and mill. Thanks again!

-

Hi, Ok, I'm learning, seems the face info is the "C" in the number so a 56C and a 145TC should have the same bolt face pattern and size bolts. The shaft should be 5/8" Dia. but have to check that?

-

Hi, Tried to find this on my own but info seems lacking to answer my question. I have one of the older Bader BM-2 Belt Grinders from 30 years ago and want to up grade it to a 3PH with a VFD. The Bolt face on the Bader/ Baldor Motor is a 145TC... The Motor I want to use is a 56C. Both are 4 bolt but are they the same??? Any ideas on this is appreciated!

-

Hi, You can mount it on a Post or a Table... Just remember to put something under the leg!!! I see people mount these Leg Vises and not support the leg??? Which defeats the whole purpose of the vise! Oh yea....You stole it!!! Now you need a small 3" for smaller stuff! It never ends!

-

Hi, NICE!!! I have one that size and even one smaller! Had to make a spring for it from a car leaf spring. Easy enough to do and now works great! These were made of course, to take a beating while forging HOT!

-

Hi, That is a good size anvil! Not to big or to little? Get a decent Leg Vise and a gas forge and start making things!!!

-

Hi, More, closer pics??? Thanks!!!

-

Hi BC, Well you are getting set up a xxxx of a lot cheaper than I did! With luck like that you'll probably get up one morning and trip over one of those original Bufflo Forges outside you're front door! (grin)

-

Hi Patrick, That sounds pretty wild! I think the difference comes in at commercial size and hobby size. Like I said we use the heat exchange principle all over the ship where I work and it saves money no doubt,but for a small forge,may not matter that much. I am going to use ITC-100 this time on top of the satinite and look for that to make the difference!

-

Hi Frosty, Thanks for the info! You are probably right a few more bucks spent on K-wool might get better results and be easier to do. Being a Marine Engineer, I deal with heat exchangers on the engines,evaporators,watemakers,ect. I guess I had to look into it trying to find that free ride so to speak! Jymm, sent me some photos of a burner that he uses that looks promising. I used the Don Fogg vertical for years and it worked great and all it was,is a 2" pipe with a reducer on the end as a burner! I think as long as you get the air and fuel mixed well you will have a forge! Thanks again!