-

Posts

2,236 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Francis Trez Cole

-

I guess it what you are more accustom to and availability of the steel. I like a hammer that will harden up to 55 rockwell and do not need any thing harder. I have been making hammers for about 4 years and 4140 and 4340 are always available to me at my local supplier and at a lesser coast they hold their drops for me. I do not mind oil hardening. Now when it comes to a drift or a punch I like w-1 or h-13 http://www.diehlsteel.com/technical-information/steel-characteristics-comparison-charts.html this chart is one of the resources That I have used in the past to help with selection of tool steel

-

Burkey on you second photo you should put a grove down the center of you tongs it will help you hold square and round stock

-

First I would have no trouble using re bar. I have had mild steel tongs break as well. The biggest thing is to use large enough stock to make the tongs. For most of my tongs I start with 3/4" stock. Glenn has posted a chart of the different dimensions of the parts of the tongs. That being said start out making flat jaw tongs the key is to get the 3 steps mastered. the Jaws that holds the metal. The boss that is the area the holds the rivet and the reins. with limited resources I would find a cheep drill and buy a good drill bit to make your holes. Since you are just starting out it is better to have a good hole in the center of your boss. Once you have forged out your tong blanks let them cool slowly do not quench them. hope this helps

-

The weight of blacksmiths hammers through history

Francis Trez Cole replied to Everything Mac's topic in Hand Hammers

the catalog by Henry J mcCoy company 1850 sells blacksmithing hammer from 1Lb 10oz up to 4 1/2 lb -

Mlmartin very nice hammers. I would not use W-1 for making hammers. That is great steel for making punches. The hammers I make are from 4140,4340, or even 1045.

-

First Successful Forge Weld

Francis Trez Cole replied to Dan C's topic in Blacksmithing, General Discussion

Dan I was reading through you first post and I though of a few things that might help you in your welding. first when you are prepering the piece to be welded on thin the edge that will give you a scarf and give you a cleaner weld the line in you second picture is from forcing a square edge into the parent stock. Second when you pull the piece of metal out of the fire do not waste time and heat wire brushing hit the 2 pieces together not to hard but enough to push out the flux and garbage. wire brush and then flux again reheat and weld hitting harder. Third I have found as you are pulling the piece of metal out of the fire the first time if you give it a little flick of the wrist most of the excess flux will fall off so on your first strike you will not have a big spray of flux going every ware. Hope this helps -

Start with bigger re bar and hammer the reins to a the right size then you do not have the re bar pattern that is what I do when you get a ton of the stuff for $50.00 you find lots of things to do with it

-

I make one for my wife each year from a basket twist, a snowflake, bell, even a small Russian rose with leaf. have to start on this years soon.

-

The color of flames Ok the question was asked to me by a young man what is the hottest fire. He was referring to forging in the production of a sword. Well his response to me was blue. After some talking to the guy I found out that he had learned the information from a video game. I told him he needed to get out in the real world for a learning experience. In blacksmithing the hottest fire was white. Doing some research this is what I found on the internet. A flame is a mixture of reacting gases and solids emitting visible, infrared, and sometimes ultraviolet light, the frequency spectrum of which depends on the chemical composition of the burning material and intermediate reaction products. In many cases, such as the burning of organic matter, for example wood, or the incomplete combustion of gas, incandescent solid particles called soot produce the familiar red-orange glow of 'fire'. This light has a continuous spectrum. Complete combustion of gas has a dim blue color due to the emission of single-wavelength radiation from various electron transitions in the excited molecules formed in the flame. Usually oxygen is involved, but hydrogen burning in chlorine also produces a flame, producing hydrogen chloride (HCl). Other possible combinations producing flames, amongst many, are fluorine and hydrogen, and hydrazine and nitrogen tetroxide. The dominant color in a flame changes with temperature. The photo of the forest fire is an excellent example of this variation. Near the ground, where most burning is occurring, the fire is white, the hottest color possible for organic material in general, or yellow. Above the yellow region, the color changes to orange, which is cooler, then red, which is cooler still. Above the red region, combustion no longer occurs, and the uncombusted carbon particles are visible as black smoke. • Typical temperatures of fires and flames of a chemical nature • Oxyhydrogen flame: 2000 °C or above (3600 °F) • Bunsen burner flame: 1,300 to 1,600 °C (2,400 to 2,900 °F) • Blowtorch flame: 1,300 °C (2,400 °F) • Candle flame: 1,000 °C (1,800 °F) The temperature of flames with carbon particles emitting light can be assessed by their color that is the burning of wood, charcoal, coal and coke. • Red Just visible: 525 °C (980 °F) • Dull: 700 °C (1,300 °F) • Cherry, dull: 800 °C (1,500 °F • )Cherry, full: 900 °C (1,700 °F) • Cherry, clear: 1,000 °C (1,800 °F) • OrangeDeep: 1,100 °C (2,000 °F • Clear: 1,200 °C (2,200 °F) • White • Whitish: 1,300 °C (2,400 °F • Bright: 1,400 °C (2,600 °F) • Dazzling: 1,500 °C (2,700 °F) Oxyhydrogen may produce the hottest flame but I seriously doubt any of us will be setting up a forge to use Oxyhydrogen as a fuel source.

-

Blacksmith in the news

Francis Trez Cole replied to BIGGUNDOCTOR's topic in Blacksmithing, General Discussion

great story thanks for sharring -

Forging in an igloo!

Francis Trez Cole replied to Crazy Ivan's topic in Blacksmithing, General Discussion

bet you would have no trouble forging here http://goscandinavia.about.com/od/scandinaviahotels/ss/icehotels_9.htm You could get a co2 meter or just bring a Canarie with you for the day if it dies get out Its Carbon Monoxide(CO) that kills you Carbon Dioxide (CO2) just displaces air. -

This year at the Faba conference we had three different challenges. The first was for beginners to take a piece of 5" x 1/2" round and draw a long taper the longest one. The second was for advance smiths take a piece of 5"x 1/2" round and in three heats slit and drift a 1/2" hole draw a long taper then thread it through the hole. The longest pass through won. Third was taking a piece of round stock 1'dia x 3 1/2" and in a team of 2 one person striking and one holding with a time limit of 10 min make a cube and switch striker holder after five min. LDW Your pres David was down and enjoyed the event. one of the other competition I saw pictures of was 2 people each made 1/2 of a pair of tongs and they had to put them together. Looks like a lot of fun as well.

-

I would not know the science of a flame but when I run my coal forge the coal burns at the hottest white and the metal is white hot I will have to look closer tomorrow. also when I keep the fire yellow the heat of the metal is a saturated yellow. this is out of wikipedia I see no blue on this list. Temperatures of flames by appearance The temperature of flames with carbon particles emitting light can be assessed by their color:[10] Red Just visible: 525 °C (980 °F) Dull: 700 °C (1,300 °F) Cherry, dull: 800 °C (1,500 °F) Cherry, full: 900 °C (1,700 °F) Cherry, clear: 1,000 °C (1,800 °F) Orange Deep: 1,100 °C (2,000 °F) Clear: 1,200 °C (2,200 °F) White Whitish: 1,300 °C (2,400 °F) Bright: 1,400 °C (2,600 °F) Dazzling: 1,500 °C (2,700 °F)

-

nice try you are getting it the next part you will need to work on is the boss (hinge area). that should be flat like the other set you made. Also be careful the area that holds the stock should be very even. If not the will tend to twist under pressure and the force of you hitting the metal they are holding.

-

Ok I picked up this one from some school students a few weeks ago. The question to me was of course about sword. Then I was asked did I know the hottest fire was a blue fire. Really was my response. After talking to the Kid a few minute's His misiformation had come from video games. So I said to him that he needed to put down the video game and get out side more his teacher broke out laughing. A blue flame was good for cooking but not for forging. So now when I get a bunch of teenage kid watching me do a demonstration I ask what is the hottest flame. Its good to mess with kids and expose them to the real world

-

-

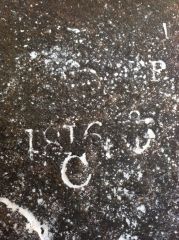

Anchors and Chains

Francis Trez Cole replied to macbruce's topic in Blacksmithing, General Discussion

there are several steps that you do not every day. First the use of a puddle forge to pick up hunks of molten wrought iron. Then there is the scarf to attach the 2 parts of the anchor. the use of filler material to fill the gaps when welding up the two parts of the anchor. then in the beginning the placement of the forge weld on the links is on the side not the ends. it is a great video -

nicely done

-

How did YOU get started smithing?

Francis Trez Cole replied to nankbrown1227's topic in Blacksmithing, General Discussion

My journey started a while ago and my bio tells the whole story -

What is this hardy tool used for?

Francis Trez Cole replied to utaholdiron's topic in Tools, general discussion

steve should have read your whole post LOL ] -

I have used the balls from King they are great but most are ductile iron

-

What is this hardy tool used for?

Francis Trez Cole replied to utaholdiron's topic in Tools, general discussion

it could be for holding a piece of metal square so when you hammer you get a specific angle bend. -

Forge both pieces for tongs at once?

Francis Trez Cole replied to windancer's topic in Tools, general discussion

I make these blanks under the power hammer leaving 4" full size and keep a couple in my tool box in case I need a set of tongs when I am doing a demo. I learned a lot from this video -

Here is a good starting point. Your shapes and size will fit the job. It just depends what you want to make. I have a picture of an old set and I will try to find it I did a handout for the class on chisel making that has the different styles from that photo http://www.mettleworks.com/sales/renzetti-tools/Renzeti-tools.html