Tubularfab

Members-

Posts

65 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Tubularfab

-

Advice on a used "American" (?) anvil

Tubularfab replied to J_B's topic in Anvils, Swage Blocks, and Mandrels

Have you asked him about its twin in the background of your last picture? It might be in a little nicer shape from what little I can see - worth asking about. It's interesting that both have the same rectangular handling hole on the base... -

I was given a Peter Wright Anvil but...

Tubularfab replied to Worshipdrummer's topic in Anvil Reviews by brand

The strength properties of any solder that has a low enough melting point to not affect the heat treatment of the face plate are going to be so low that there is no hope of it lasting. It's a noble thought - but it just isn't going to work. Solder and shock impact loads don't mix. -

I would cut a piece on the water jet and braze it in. I saw one of those forges yesterday in working order for $400. I really would like to have one...

-

Nut coal

Tubularfab replied to Small town Smith's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

Nut coal was all I could find in Georgia stores. Seems to work just fine - and I can always make it smaller with a hammer... -

There were a lot of things he had that I wanted! Budget and prudence won, though. He has a champion cavalry forge (the square, cast iron one) that I really wanted to take home, too. I'm sure I'll be visitting him again in the future!

-

It's home now. It's in really good shape with the exception of a crack in the face plate only at one side of the hardy. The crack does not go into the cast body. The guy was pretty cool - he's into collecting all tools. On the blacksmith tools he lets you trade up down the road if you want bigger or better. He even has broken anvils in the back for budget starters that he said have been through several users that later upgraded with him.

-

Nut coal

Tubularfab replied to Small town Smith's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

You didn't look too far down the recent posts in this forum: http://www.iforgeiron.com/topic/43617-coal-at-local-tractor-supply/ I just bought 10 bags myself. It was hard to get burning, but seemed quite usable once going. I don't have a lot of options where I live, so going to give it a try... -

I was going to leave price out of since it varies by area and really only matters to the buyer and seller. He's asking $2.50 a pound, which isn't awesome, but better than I was expecting from a reseller. I've been watching the area for about 3 years now, and really haven't seen much for sale above 120lbs, and if so at much higher prices. I've actually avoided calling this guy figuring he was going for top dollar as a reseller. I talked to another local reseller that offered me a 200ish lb "collectible English" anvil at only $2000. There was another one about 130lbs for only $800. He figured his old English stuff was mostly $10 per lb and higher... I have an 84lb Wilkinsons that I bought for almost nothing due to the top plate coming off. It was in really bad shape with only about 20% of the plate still attached. With a donation from my local Lincoln rep of a box of tough facing rod I built it back up and it now has pretty good rebound. I like it, but really want a wider face to work with. Seems like I am always dropping stuff off it when veining, etc. I think the 3+ years on the repaired anvil paid the dues to warrant getting a really nice one... Plus, my sons are getting interested and I thought I'd mount the little one lower for them.

-

Ok, so the 172lb English anvil got away, and I am now looking at a 200lb Fisher. The owner says it's dated 1919. I have to travel a bit to get it, so I have not seen it in person yet. Anyway, is it just me, or does this one seem to have an extra-long horn? Just looking at other Fisher pics online, this one looks elongated. Also, I see it has mounting lugs, when many I see online don't. Is this just a slightly different pattern than others? I seem to remember NJAnvilman saying somewhere that Fisher had a huge number of patterns... For some non-mattering reason I tend to like the looks of the 1800's English anvils like Mousehole, Wilkinsons, and PW, and hadn't really considered going with a "newer" American one... But, from what I read the Fishers are great to use.

-

170lb - Anvil or really nice shaped ASO?

Tubularfab replied to Tubularfab's topic in Anvils, Swage Blocks, and Mandrels

That anvil got away. The owner had agreed on a trade, and then backed out and sold it elsewhere. Overall he was pretty obnoxious to deal with, and I'm not terribly upset to not have to deal with him again! -

anyone doing this with their kids?

Tubularfab replied to natenaaron's topic in Blacksmithing, General Discussion

Yes, this was a 5 minute test to see how much they really want to get into it. The anvil is too high for them, specially the youngest. But, they got a couple of wacks in with the hammer, and I am certain they will want to do more. So, time to find more PPE for them! -

anyone doing this with their kids?

Tubularfab replied to natenaaron's topic in Blacksmithing, General Discussion

My boys drove me nuts asking to try this when I switched over the patio from summer to blacksmith mode this fall. They listened carefully and gave it a good try. They are 5, 8, and 9. Biggest challenge was the smallest safety glasses I had were still too big. I need to figure out where to buy smaller ones. Most of the time I was right with them, but had to step back and get some pics of course! -

170lb - Anvil or really nice shaped ASO?

Tubularfab replied to Tubularfab's topic in Anvils, Swage Blocks, and Mandrels

Yeah - I was halfway there when I remembered I left my hammer next to the door at home. Amazing how easy 3 boys (5, 8, 9) can distract you getting ready to go somewhere! That hammer was one he produced when I asked. There is definitely rebound, just didn't strike me as great. But, I was wondering if the mostly plastic hammer was absorbing some... Looking at the pics I do think I see a 0 where you'd expect to see the "remainder" pounds of the hundred weight. Wirebrushing might reveal more... I think we've agreed on a trade deal, so this weekend I'll be able to study it closer. Thank you for all the input! -

170lb - Anvil or really nice shaped ASO?

Tubularfab replied to Tubularfab's topic in Anvils, Swage Blocks, and Mandrels

Yep - with the pointed feet it definitely looks like a Wilkinsons or Mousehole. My concern starts with the seller saying he had a few anvils, and a collector had come out to evaluate them. He decided this one was not good, that it was cast iron. Of course they were very hung up on it not ringing. And the seller is not that familiar on this stuff - he could be confused and saying cast iron instead of wrought iron... But, with the seller saying it was not a good anvil... -

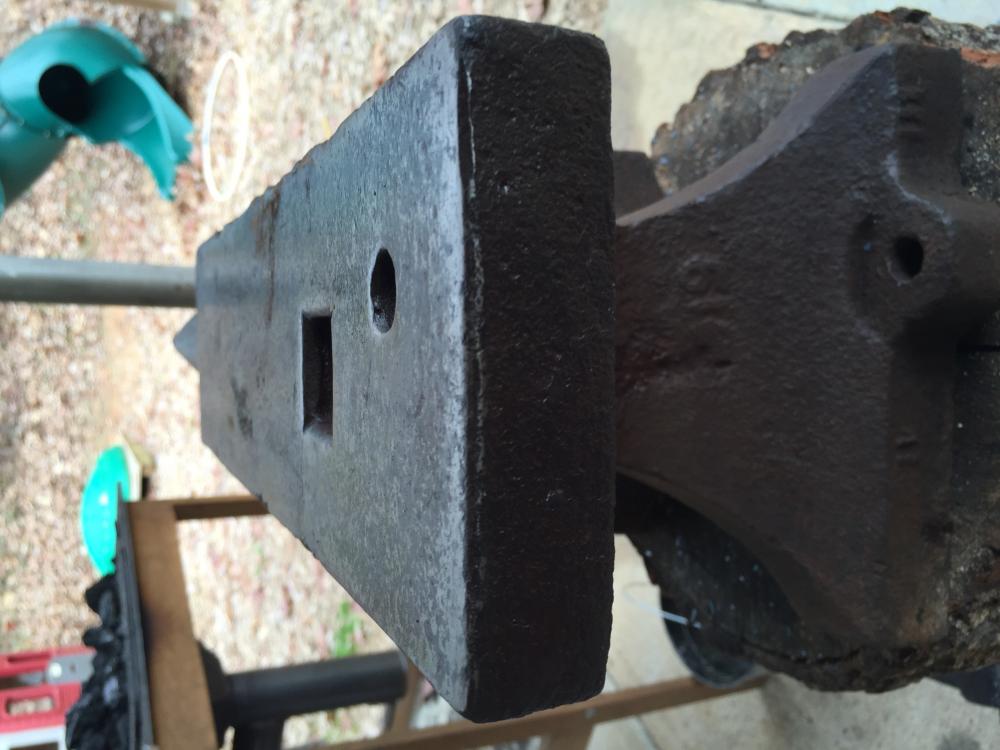

Ok, I just looked at this anvil tonight in the dark - by tractor light. It was painted black a long time ago, and now is mostly rust. With the light I had I could find no markings on either side - looked with my eyes and by feel. It has seen a lot of use over time, but is in pretty nice shape. Rebound is not awesome, but there is some. It's fairly quiet. I don't see or feel any casting parting lines. There is no obvious line from a top plate. Please take a look at the pics and toss your opinion out. It would be a nice size increase over my 84lb Wilkinsons, but the appearance is making me think it's a cast copy of a good anvil. I was really rushed looking at it; with a little more time to study it I could have been more confident. So, what's really confusing me - are there ASO's of this size and looking this much like a typical London Pattern anvil out there? Thank you!

-

So where is the 300lb one? If the price per pound is the same...

-

Interesting old hammer I found

Tubularfab replied to Wicked97's topic in Power Hammers, Treadle Hammers, Olivers

After HWool's last post I blew the pics up bigger and finally see where it appears the vertical link attaches to the "helve" arm. Before it looked to me like only the rope connected the helve to the hammer - making me think drop. Something must be off in the connection of the hammer slide to the helve, though. The helve appears to be about centered in travel, and the hammer slide looks bottomed out. This was also a factor in my thinking drop... Ok Wicked, let's get your priorities straight - forget the harvest and get to work on this hammer! -

Interesting old hammer I found

Tubularfab replied to Wicked97's topic in Power Hammers, Treadle Hammers, Olivers

Actually, I don't think this is like a guided helve if I understand it correctly. It simply a drop hammer with nothing but gravity to make the hammer drop. Still very cool, but not as fast as a full power hammer. I'd take it! I was at the North GA Fall Mountain Festival over the weekend and the blacksmith shop there had a Mossberg and something or other drop hammer. It used a leather belt to raise the hammer, then gravity drop. Had a nice, small footprint. I don't think it has been used lately, though. -

My anvil is uglier than yours!

Tubularfab replied to stuartthesmith2's topic in Anvils, Swage Blocks, and Mandrels

I think this Mousehole has given all it had to give. It would have been a decent size - probably around 130lbs. It's been sitting at a local antique shop for years. I need to ask the price one day and just buy it to sit around for conversation reason and make my repaired Wilkinsons look amazing! They also have this Peter Wright 1-0-11 that has been pummeled with dents for $400... -

Man - such negativity on this thread... At this rate nobody should be fixing up old machines. Yes, it needs work. If you're willing to do the work, and you do it yourself instead of paying someone, and you derive great pleasure and satisfaction from saving a really cool chunk of machinery - do it! I'd love to have that much of a machine to rebuild into one. Seems like a way better investment to put the energy into repairing this than put the same amount of work (or more) into building a less effective machine from scrap and an old tire...

-

Watching your videos cures me of my complaining that the face of my anvil is too small! They do make my back hurt, though. That stump looks like it would really be in the way on that side of the rr track. Great examples of what you can do with very little in the way of tools! Nice first leaf, BTW!

-

Is This Little Giant Worth the Price?

Tubularfab replied to Jakesshop's topic in Power Hammers, Treadle Hammers, Olivers

That one in the last pic isn't strapped together, it's "reinforced" like its an improvement if you read the listing... Because everyone preemptively puts a giant, ugly strap on a hammer to make it stronger! -

how not to anchor an anvil

Tubularfab replied to rlbaker's topic in Anvils, Swage Blocks, and Mandrels

Could you use a very small diameter cable to saw through the silicone? -

I'm using an early 1990's Koike Ductmaster 5' x 10' table that I bought pretty much for scrp price. It was still functional, but the controls were horrible, and to get software to interface it was super expensive considering it was 20 year old technology. It came with a 100amp Thermal Dynamics dual gas plasma cutter of the same vintage. I switched the motors over to big steppers and set it up to run on Mach3 software that turns a PC into a cnc controller. I actually bought a great arc voltage sensing torch height controller but have not yet installed it. The old plasma cuts well and tips for it are dirt cheap. And, I know the machine well enough to fix it if theres an issue. Here it is cutting: http://www.youtube.com/watch?v=gCbhcdxcLEM&sns=em