-

Posts

274 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by neg

-

Wow, that really makes a huge difference. It's beautiful now, and the pin in the side matching the one in the bottom of the pommel is perfect. Really, really nice looking sword. Makes me want to do one.

- 16 replies

-

- union forge

- bladesmith

-

(and 1 more)

Tagged with:

-

Got a picture of this completed? Yeah, it might not be your design, but it's one of the most awesome blades I've seen and you really did a great job on it!

-

I saw that somewhere before, too, and wondered the same thing. I really like it a lot.

-

You'd be surprised at how much material is in the last 2 inches of that spike. You can get a pretty good sized blade out of it.

-

Looking good. I'd be worried about rain blowing in on all my tools, but that's just me. I especially love your sign, did you do it yourself?

-

Forget that, just use a break drum. You can get one cheap from any scrapyard. You can pick up some steel to forge while you're there, too.

-

It looks great for even your tenth knife, let alone your first! I look forward to seeing it finished.

-

What are your opinions on this anvil?

neg replied to Forging Carver's topic in Anvils, Swage Blocks, and Mandrels

It looks usable, but pretty soon you'll be wishing you had a bigger anvil. -

My touchmark is probably 4" long. I really wish it were longer, I just end up burning yourself trying to hot stamp things with it. You'd think you could just hold it with tongs and it wouldn't be a problem, but when you mess up or don't stamp deep enough and have to realign the stamp on the steel, it can take some time and it's hot.

-

I totally agree with you when it comes to blades. I only have my one touchmark, it has my logo and then my name under it. I love the way it looks, but on my blades I'd like to get one with just my name. On metal work other than blades though, I think the bigger and more elaborate the touchmark, the better.

-

think it's great. The Fs raised up a little bit look like a shoulder with pauldrons. It scales okay, as long as you don't want it super small.

-

The blade looks pretty nice for a first time. Could be made to look good if it had a proper handle, not made from belts (no offense).

-

Those were the only pictures I took before I gave it away. It looks really nice close up though. I had a layer of leather in there, but if you try it, leave the leather out. It delaminated and the resin wouldn't hold it. After it dried I had to epozy it to the micarta to get it to work right, but it was a hassle.

-

I started out with a leather apron, but here in florida it gets pretty hot, even without the forge. I usually just forge in a t-shirt.

-

Honestly, I'm not real familiar with wood stabilizing. All I've ever done is find some nice old, dried wood and put on multiple coats of tru oil

-

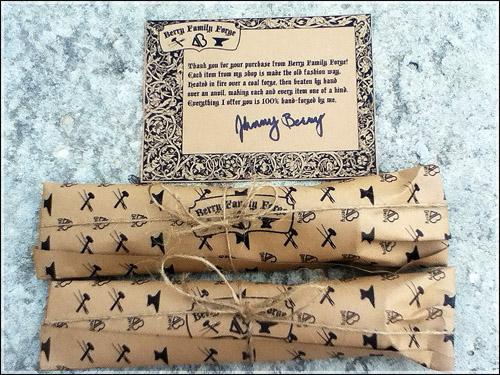

Here's the cheap way I found to do mine. I made a pattern with my logo, tongs and hammers, and my anvil in photoshop, then printed it up on some card stock. Then I got some cheap twine from the dollar store and tied it up. Finished it off with a signed card to the customer. It only costs me a few cents for each one and I think it looks a whole lot better than shipping them in a toilet paper roll.

-

I just realized I haven't posted anything in a long time. Here's a few I've done over the past few months: Forged this seax a while ago, and yesterday I finally decided to finish it. It's made from a large old file, hammered to shape. I chiseled in a fuller on both sides. The blade is 7", and the whole knife is 12" long. The handle is made from brass, elk horn, and wood found in my yard. Made these a while ago, one's for me and one for my wife. Both made from old Nicholson files. I made the micarta from felt and fiberglass resin. The blue and brown one's mine. I'd been wanting one of these for myself for a while. The blade is 14", making it 19 1/2" overall. The steel is leaf spring. The handle consists of aluminum, steel, elk horn, and some wood I found in my yard. Ever since I started blacksmithing, my dad's been begging me to forge a big bowie knife. Well, I was never really a fan of bowies, but after watching a whole lot of Hell on Wheels, they've grown on me. It started out as an old farrier's rasp. I did a mixture of forging and stock removal on this one. The handle consists of brass and a special micarta that I made from leather, felt, pecan shells, and tree bark. I really love how this knife turned out, so did my dad.

-

I keep two anvils, pretty close together in my forge. A large one I do most of my forging on and a small one with a sharper horn and edges that come in handy. It's also nice to have a second when a friend wants to come mess around in the forge. And believe me, they will.

-

Chisel a line down all 4 sides of your square stock, twist any number of times you wish, but remember how many. Then hammer your twist square and chisel another line to match up with your first one, then untwist half the number of your original twist. So if you gave your twist 3 full turns at first, at the end untwist if 1 1/2 turns.

-

That is my dream anvil.

-

I've never had any trouble forming them on the anvil without a mandrel. Just make a bend and start rolling it. Your corkscrew looks great, though. Haven't seen one done like that before. :)

-

It looks really awesome. Their house could use a few more of your "cosmetics"to go along with it!

-

I've got so many hammers that I only really buy Heller (my very favorite) and Atha when I see them.

-

I kind of think that when people see an anvil, they think they're from medieval blacksmiths, rather than only being 100 or less years old. All medieval movies I've ever seen depict a blacksmith's anvil in the London pattern. I could be wrong, but I think it's that ignorance that helps drive up the price.

-

2015 SE Conference May 13-17

neg replied to Dillon Sculpture's topic in Events, Hammer ins, Where to meet

I booked my hotel yesterday. I'll definitely be there.