Chinobi

Members-

Posts

1,122 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Santa Barbara, CA

-

Interests

Mokume Gane, tools, patterned metals and pattern development in other materials, edged tools

Recent Profile Visitors

8,423 profile views

-

Thank you! lamentably my phone was out of memory during most of the recent work so I couldn't get any WIP photos ;_; but for the fuchi/guard I just used a piece of flat bar with a rounded edge to mimic the curve of the leather just beneath the choil and hammered over that to shape the sheet brass, lot of hammer-fit-file-bend-repeat to get it to fit correctly! For the kashira/pommel I built a stake(riveted together two pieces of flat bar I had on hand to build up the width then chopped off the corner and radiused everything on the 1x42) that roughly approximates the dimension of the tang plus the leather and used that to form the brass. I knew trying to make a proper tight fitting joint between the two sides of the brass was going to be way too much work so I left the gap wide, which also allowed me to get some files and discs into it to clean it up, and then used a piece of flattened copper wire as a filler piece to close the gap. Kind of a tip o the hat to Kintsugi by making the 'repair' a focal element, adds a little more interest to the piece than just a silver solder line that will eventually turn black.

-

Recently finished my latest project, 3 years in the making, mostly rusting in a box, but this blade is finally done! Forged the blade in late 2014 (October sounds right, predates this phone though!) at the last ABS hammer-in in Tulare under the tutelage of Jason Knight, David Mirabile, Bill Stuart, Ray Laconico, and Michael Vagnino at various times throughout the conference. Special thanks to David for recommending "The Art of Tsukamaki" by Thomas Buck, such an incredible resource for Japanese style handle wrapping techniques, and to Ray and Mike for some blade grinding pointers (sorry guys, quality is still not there, but is improving!).Enough flapping, specs!10" OAL, 5.25" bladeStarted out as 3/16 by 1-1/4 1080 carbon steel, forged to shape.Fuchi (collar at the top, where a guard would be) and Kashira (pommel/end cap) are brass sheet that were raised/shrunk/hammered to shape and soldered together. The Kashira had a flattened copper wire inserted into the seam to fill the gap that I filed in to allow me to clean up the joint without needlessly flexing and bending the part to get files and paper in the slot.The Omote (outside, as worn) side Menuki (ornament beneath wrapping) are the cartridge ends of a .50 caliber S&W 500 handgun I fired at my bachelors party, and two .308 Winchester rounds from my rifle. These were cut off their respective casings and soldered together.The Ura (inside, as worn) side Menuki is a cut off from a copper and brass Mokume Gane billet forged in a class taught by Jay Burnham-Kidwell at Adam's Forge LA (no relation), lightly forged to a sorta teardrop shape and rounded on the grinder.Wrapping material is gutted red paracord over black leather, nothing fancy there. Finally got an edge on it just now, took it up to 600 grit on the wicked edge and then stropped on my green paddle, the edge looks terrible but it will draw blood as well as anything else. It shaves hair with minimal back and forth, makes spaghetti out of my grizzly catalog test paper, and pulls nice (my carving skills are the limiting factor) feathers out of mystery wood. It doesn't bite really deep in chopping because it's relatively light, but it's quite comfortable in hand and you can really flick it through the swing and get the work done without needing to swing super hard. Definitely need to make a sheath for this so I can take it out for some field trials in something safer than a cardboard and duct tape taco! any thoughts, comments, suggestions and advice on things to improve or keep doing would be greatly appreciated, don't worry about delicate feelings either, I can't improve what I don't realize is bad.

-

Mokume Gane and Silicon Bronze Viking Padlock (pic heavy)

Chinobi replied to Chinobi's topic in Mokume Gane

Many thanks! -

Mokume Gane and Silicon Bronze Viking Padlock (pic heavy)

Chinobi replied to Chinobi's topic in Mokume Gane

Thank you times 3 -

I'm reasonably certain that member projects is more applicable than the Mokume forum, if not, I'm sure you know where the move button is. I have admired the excellent lock work shared by Nick and others here and elsewhere so I jumped at the opportunity to get a copy of instructions and materials to make a Viking era padlock myself. I decided to up the ante a little and make the materials a little more interesting though. The top and bottom plates are spare quarters mokume and the body is a sheet of copper with a design chased into it, subsequently filled with melted brass wire and melted silver solder in different places then ground smooth to give it a kind of faux-kume look because I didn't have the time to make a fresh billet that could be forged into sheet metal big enough to make the body. The rods are 4 wires (2 copper and 2 brass) twisted together tightly, soldered solid into one bar, then forged cold to knock off the ridges and make it more of an actual circular cross section, the tops are 4mm sterling bezel cups set with lavender opals. The ward plate on the shackle is another chunk of spare mokume and the spring is nickel silver sheet metal flush riveted on with copper pins. Both the shackle and key are forged silicon bronze. The lock is operated by inserting the key into the rectangular slot on the bottom, rotating it into position and sliding it up to compress the springs, which will allow the shackle to pop through the hole in the top plate. Thanks for looking!

-

2017 California Blacksmith Assoc. Spring Conference

Chinobi replied to Chinobi's topic in California Blacksmith Assoc

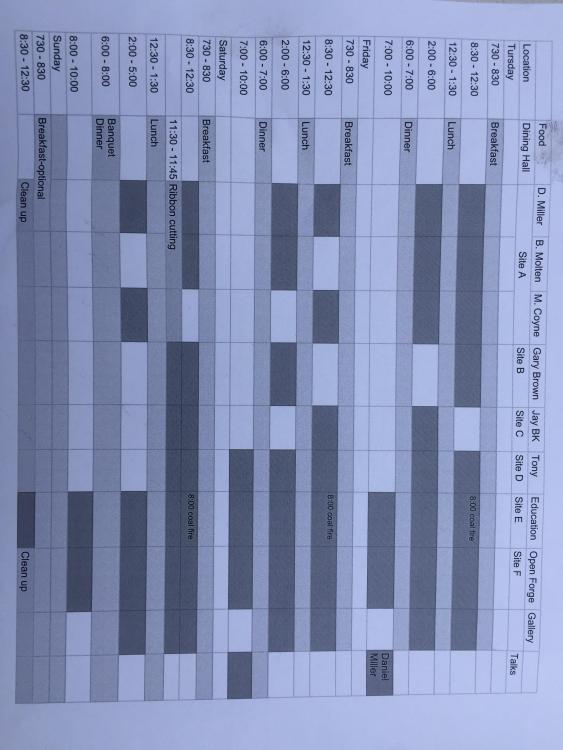

Here's a pic of the schedule, my understanding is that the greyed out boxes correspond to when that demonstrator will be demonstrating. There is a LOT of overlap, there is always a project going at the education barn, project continuation/open forge on the lower lawn, and usually 3 demonstrations happening at the same time. also some action shots of some of the demo's I caught in the afternoon; Jay Burnam-Kidwell using a hardie block and set hammer to forge out a tenon, and Tony Swatton showing a variety of sheet metal techniques on a scrap of aluminum. Loads of fun and good times to be had if you can make it to the event- 7 replies

-

- california

- cba

-

(and 3 more)

Tagged with:

-

2017 California Blacksmith Assoc. Spring Conference

Chinobi replied to Chinobi's topic in California Blacksmith Assoc

I don't think I have see a schedule for demonstrator events yet either, just the hands on and workshop stuff. I will be heading over there shortly so I will try to remember to ask, if we are lucky they will have a paper schedule for attendees that I can snap a pic of and post. last call for the rest of you all to get your effects in order and get down to vista for the event!! hope to see some of you soon- 7 replies

-

- california

- cba

-

(and 3 more)

Tagged with:

-

Put the money you would spend on a billet towards a Damascus making workshop IMO join ABS(sorry for the plug, but I've met a lot of great people through them, some tools, but many greats) and the Washington Blacksmith Association, they must have some kind of classes every once in a while.

-

Excellent posts! Subscribed for the next lessons too, thank you for sharing!

-

2017 California Blacksmith Assoc. Spring Conference

Chinobi replied to Chinobi's topic in California Blacksmith Assoc

Anvils shall be struck as directed, with ferocity good luck with the replacement, I hope there is little to no excitement involved, except that of successful completion!- 7 replies

-

- california

- cba

-

(and 3 more)

Tagged with:

-

Rob Thomas and Chad Nichols are household names in the custom knife community for high quality Damascus purveyors for stock removal knifemakers. George Palagonia of American Metal Xchange sometimes has Damascus or Timascus/Mokuti available. Tru Grit Inc has a section for blade steel stock that includes a selection of Damascus products dont hold yourself back from buying pattern welded blade stock to start with, it's a little more expense up front and a little more heartache when something goes sideways but otherwise it's just steel. Get the HT instructions from the supplier or tell your HT vendor what it's made of so they can do it right.

-

2017 California Blacksmith Assoc. Spring Conference

Chinobi replied to Chinobi's topic in California Blacksmith Assoc

Please do! Great organization and Vista is indeed an awesome venue and event- 7 replies

-

- california

- cba

-

(and 3 more)

Tagged with:

-

Hey all! Been fairly quiet lately but wanted to post a reminder for my California friends and neighbors that CBA Spring Conference is once again at hand, and will be in Vista (just north of San Diego) at the Antique Gas and Steam Engine Museum! Check out the website for up to date details and registration infos. Cheaper registration cutoff is presently April 10th, so strike while the iron is hot! (Shameless, I'm sorry >.>) http://calsmith.org/event-2418120 Demonstrator list as of this posting: Daniel Miller Brett Moten Monica Coyne Tony Swatton Gary Brown Jay Burnham-Kidwell Helmut Hillenkamp There's a wide variety of projects slated for the education barn under the tutelage/lash of various guest instructors. This is a coal forge zone, so read up a bit beforehand if you haven't had much time playing with them yet, they will show you how to do it but it makes it so much easier for you to learn if you do some homework beforehand! The food is great and plentiful, I suggest adding the meal plan (so much easier...). The museum itself is really cool to check out too, they have hundreds of old steam powered machines on the grounds and a vintage lineshaft powering tools in the barn off a really old kerosene (if memory serves) engine (fingers crossed that it's still in working order! :-D ). The power hammers are a lot of fun sound off if you will be attending! I'll be flying an IFI T-shirt at least once, might figure out another insignia at some point, TBD. hope to see some of you there!

- 7 replies

-

- california

- cba

-

(and 3 more)

Tagged with:

-

Thanks Steve, that was a lot of fun XD I was going to feel bad for all that equipment in the rain...until they killed them all! O.o

-

Question About "Wrapped" Style Axes/Hawks

Chinobi replied to NFLIFe's topic in Axes, Hatchets, Hawks, Choppers, etc

Add the tag "site:IForgeIron.com" without the quotes after your search words to search this website only, helps weed out a lot of clutter!!