metalanton

Members-

Posts

80 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by metalanton

-

thanks, that is definitely sound and very wise advice. How about the idea of using the compression stroke of the cylinder as the forging stroke and/or eliminating guides?

-

I recently came across a pile of hydraulic cylinders at the scrap yard that were something like 5" bore and 30" long.. i didn't have a tape measure. anyway, I wanted to build a fairly compact forging press kindof like randy mcdaniel's H-frame so i decided to pass on these. Now that i have been thinking about it, i thought maybe a press could be made in which the cylinders are configured like a KA75, so that the compression stroke of the cylinders would close the dies of the press. I understand that the compression stroke of these cylinders has less strength than the extension due to the reduced surface area from the piston rod on the compression stroke. but In this case i think it would only reduce the tonnage by 5 ton or so, so not a big deal. So my idea was to mount the two cylinders vertically with the pistons pointing up and create a solid base and bottom "anvil" for supporting the cylinders. Then I was thinking that the upper die could be made quite sturdy to alleviate any torsion between the two pistons and ensure that they travel parallel and in synchronicity... but this would require that the pistons take on the guiding of the upper die.. this to me would be a huge advantage in ease of construction since no other framework would be necessary for guiding the upper die. My questions are the following? Has anyone done this? I am thinking if no there must be a good reason Does anyone with hydraulic cylinder experience know if the pistons will guide the dies effectively and most importantly safely? Used hydraulic cylinders any good? I have heard of others using cylinders from the scrap yard, are they usually rebuildable, or not worth the trouble.. they are tie rod cylinders probably from a backhoe. i could get them for 40$ each probably

-

I sent clay an email for you, hopefully he will contact you

-

I just ordered a set of plans through his email clay@tirehammer.com. I sent payment by paypal and he immediately sent the plans by email... maybe just send him 32$ by paypal and describe that you want him to email the plans.... the plans are excellent and very thorough, worth every penny. when you buy the plans you agree to only build one hammer and not sell the plans to others. sorry.

-

looks mighty nice, where did you get your hydraulic cylinder?

-

Flattening thin copper strips - what would work best?

metalanton replied to Gerome's topic in Copper Alloys

Rolling mill for sure. Harbor freight used to have a decent one. I sold my harbor freight one for twice what I paid for it on ebay... I now have an antique one that I bought for a 100$ on craigslist -

I am drooling

-

silver steel, integral bolster chef knife

metalanton replied to matei campan's topic in Knife Making

Elegant perfection! -

Any Goldsmiths on the site?

metalanton replied to Glenn's topic in General Metal Specific Discussion

I do metalanton.com. Thanks anton -

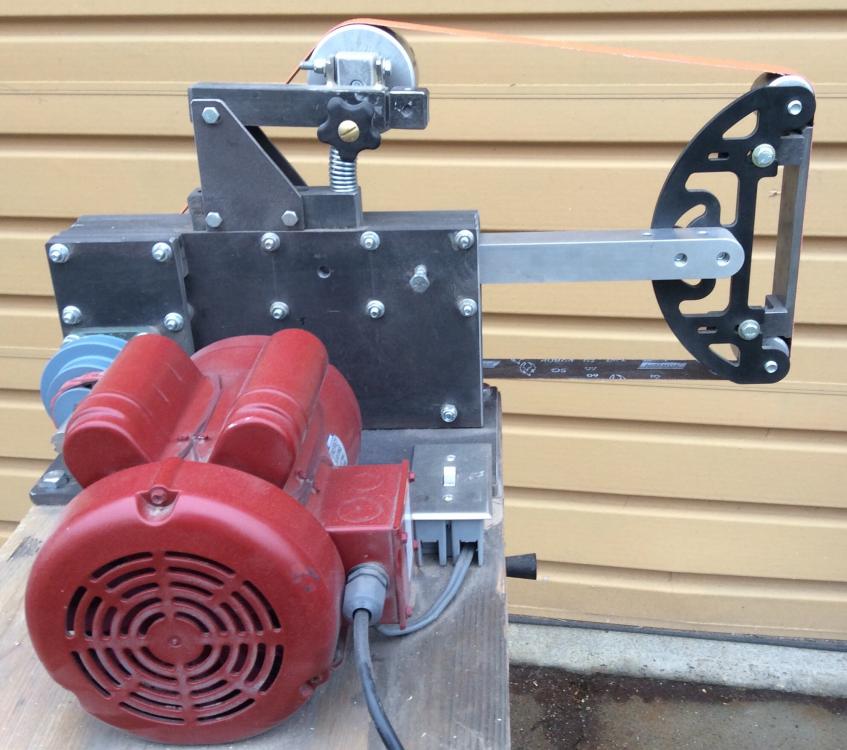

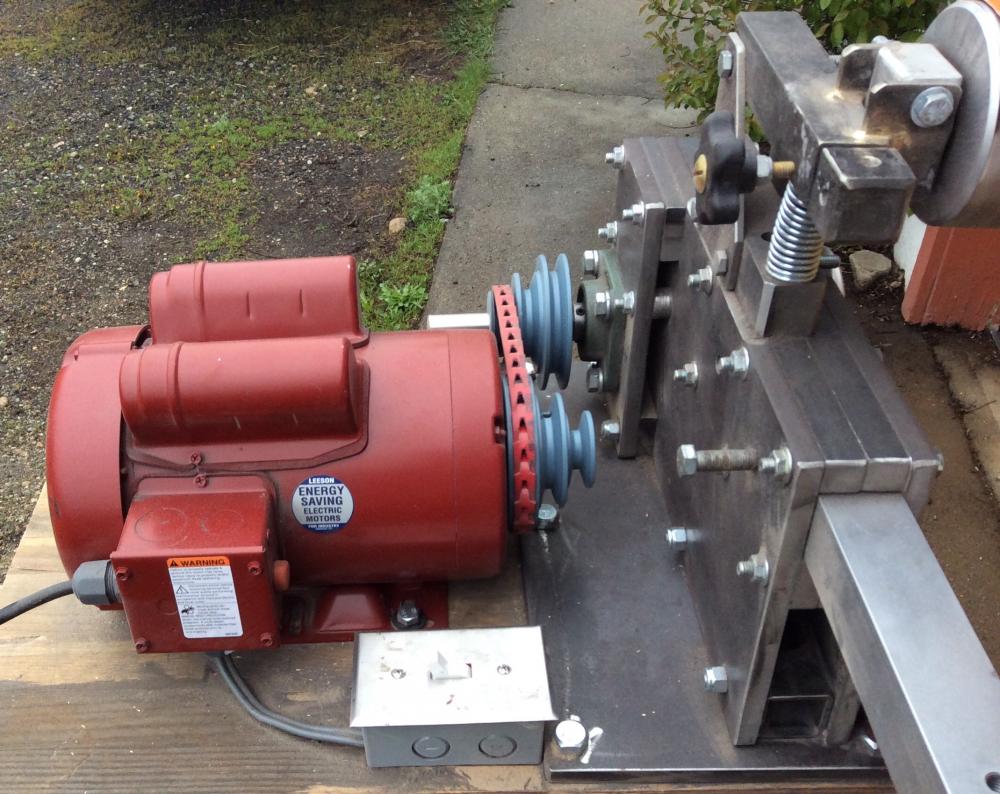

This one is quite heavy and even with heavy grinding I can't move it off the workmate that the base is sitting on temporarily! I should weigh it. I am sure it is around 150 lbs.

- 6 replies

-

- belt grinder

- knife making grinder

-

(and 1 more)

Tagged with:

-

Thanks, I hope the plans are easy to follow!

- 6 replies

-

- belt grinder

- knife making grinder

-

(and 1 more)

Tagged with:

-

- 6 replies

-

- belt grinder

- knife making grinder

-

(and 1 more)

Tagged with:

-

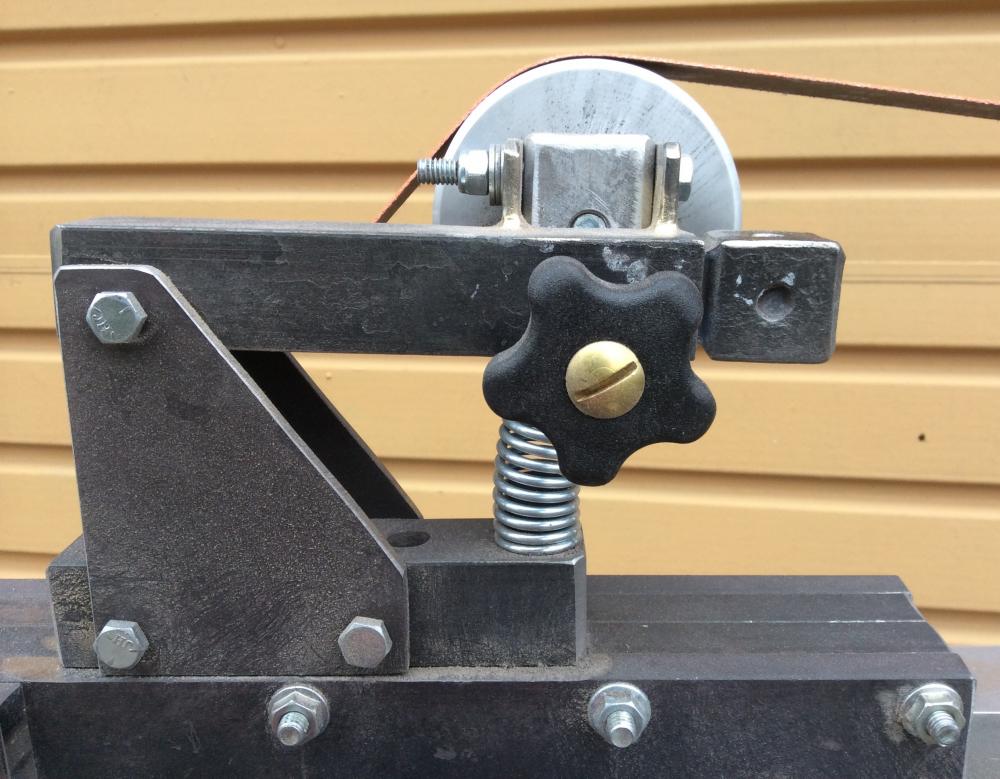

I have just put together a blog tutorial on how i built my belt grinder. It is heavy with pictures and dimensions for the do it yourselfer. I hope you enjoy... please comment if you think i should change or edit anything. thanks. http://metalantontools.blogspot.com/2015/05/metalantons-2-x-72-belt-grinder-build.html

- 6 replies

-

- belt grinder

- knife making grinder

-

(and 1 more)

Tagged with:

-

They are made in Pakistan, by the same factory that make tom tongs. They are very nice tongs, but have minor manufacturing inconsistencies but for the price are still very worth it. I sure like the look of quick and dirty tool tongs though and made in the USA...they seem like nice guys too.. Although the service @ centaur is hard to beat as well.

-

I forged a few top tools last week. One slitting hammer from 1" 4140, one half inch top fuller from 1.4" 4140 and one 5/8" top fuller from 1.4" 4140. I didn't get the cheeks drawn out quite like I wanted but I think they should work quite well. Used my belt grinder to make them a little prettier.

-

Feel free to practice forging on copper, copper forges almost identically to .925 sterling silver. That is forging cold and annealing between rounds of forging. If you forge copper hot it can take a lot more heat than silver, while silver can just fragment or melt off when forged too hot, so deserves a lot more care. Sterling silver , although slightly harder to forge and more prone to fire scale than fine silver will result in a more durable end product due to its increased hardness

-

Blacksmithing DVD Question

metalanton replied to Gobae's topic in Axes, Hatchets, Hawks, Choppers, etc

I have Jim Austin's asymmetric axe video, and it is very well done, shows clearly every step and has some good tips on tempering and getting a good weld through the eye. It shows the tools needed for making an axe with a striker, so you will have to modify a bit to do one without a striker. The video is professionally produced and i had one question to bother Jim about, and he was happy to shoot an email back at me, so I appreciated the customer support. Mark aspery has a YouTube video that shows a wood axe being made with a symmetric wrap that is 3 min. Long and an excellent primer for the more complex Viking axe form. -

Looks pretty perfect to me, very elegant design

-

Interestingly copper also has bactericidal properties and in Brazil where a lot of copper mining is being done they actually made a beautiful hospital with all copper surfaces. The rate of hospital related infections decreased by a significant amount, so much that the hospital in Los Angeles is doing trials with copper surfaces and rails on beds, etc. when my wife was breast feeding she had some trouble with mastitis and I forged a copper nipple for her. The mastitis went away within a day every time.

-

Before I go and spend a bunch of money

metalanton replied to Wernher's topic in Anvils, Swage Blocks, and Mandrels

The German anvils are top notch.. Although I would personally go for a refflinghaus over the ped. That kohlswa looks nice. Rhino anvils have a great reputation and have a 130lb anvil for around 950. -

Nice design, I really like that you can use it to hang things as well. Leaves are a nice touch and love the nails. A complete piece in every detail!

-

Don't forget that metals have inherent healing properties and having them contact the skin can be beneficial for certain conditions. An example is copper for arthritis. Interestingly I wear copper everyday and never take it off and it has not dis colored my skin at all, but I have patients that have severe joint problems and arthritis and their body chemistry seems to oxidize the copper overnight. I think these reactions are due to the acid/alkalinity imbalances in their body and the fact that negative ions build up at injury sites. Copper being positively charged counteracts this. So tell your clients if it turns their skin green they need it!

-

search brazeal style anvil, just a simple piece of 2" thick mild steel on edge, with different radiuses for drawing.. I used one before finding a "real" anvil and I still use it all the time, very versatile. youtube has a video on making one too.

-

Autoclave stainless steel small propane tool making forge

metalanton replied to metalanton's topic in Gas Forges

yes, the workmate is temporary, will eventually mount it on a pole driven into the ground. I would never abuse my workmate! it has served me well and is a great design, for lightweight and general handiwork. they should make a blacksmith version that weighs a couple hundred more pounds -

Autoclave stainless steel small propane tool making forge

metalanton replied to metalanton's topic in Gas Forges

Thanks frosty, coming from you, I really appreciate the compliment, I will see what a little extra fuel will do! and post some fiery pictures