Buster Bolster

Members-

Posts

41 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

North of Pittsburgh

-

Interests

Woodworking and Toolmaking

Recent Profile Visitors

-

Those 10 in figures are video with ruler. They're actual. The marks are probably not what others would consider marks and nothing at all like a hammer strike. You can just tell that the anvil has been used. My daughter put a hammer strike in it, though. Just a small ding, but she completely missed metal with a 4 pound hammer and with the head turned.

-

Amateur Chisel Making

Buster Bolster replied to Buster Bolster's topic in Chisels, Gouges, Scissors, etc

Thanks - i did see a lot of spray and steam as the material went between rollers. I wondered if it was for cooling the scale and blasting it off or if it was for temperature control of the rod. I also wonder if the speed and force of the rolling could maybe keep more heat in the steel than you'd want - or in crease it. As a side note, after tempering the chisel above, I'd forgotten about the ability of 52100 to buffer a bit of the initial effect of tempering. As in, you temper something with iron and carbon it it and just a little manganese and trace of chromium (like 26c3 or 1095), it starts to drop hardness. If you compare something that converts some martensite at low tempering temperatures - like AEB-L, the hardness sort of holds steady and then drops. I'm guessing that the fall off of 52100 is less. why? the chisel after a 400F double temper remains at 64.5 hardness. Brine is a treat - even as the cross section thickens well up the chisel, the hardness is 63. -

Lost one of the ball bearings by the way. I set out to come here and put some accurate info out there for the competitor since I really couldn't find any. Final word on it - it marks a little easier on the surface than my possibly soderfors anvil, or whatever it is, it's a good vintage anvil. But, working hot metal, the marks that I have on the surface of the JHM after several hours of very heavy hammering to draw out high carbon bar are the kind of thing where maybe it will need to be resurfaced after a couple of thousand chisels, and probably if I have to do that, the slightly lower hardness will be a treat for that. Resurfacing a 60 hardness anvil of any size has to be a bear. 80% rebound and maybe slightly less than that if the drop is higher is still fine. And at least at this point, the anvil will show up at a decent truck freight rate, the shape is nice for me (big horn, big flat working surface - farriers shape but maybe big enough that operations more typical on a 125 pound farrier's anvil might be awkward). the heft is nice for my purposes and if I ever run across a dandy 300 pound vintage anvil for a song, then it'd be a more interesting comparison. I may be back in the future at some point, not sure.

-

ever so slightly over 80% for JHM, 90% for the smaller anvil.

-

Amateur Chisel Making

Buster Bolster replied to Buster Bolster's topic in Chisels, Gouges, Scissors, etc

Same procedure for a chisel in process with 52100 bar and I think I've mastered getting the retained austenite out of it so it acts like a more plain steel in a chisel (less tough, but more strong as far as edge stability goes). 68.5 hardness out of a brine quench and quickly into the freezer, and that being after thermal cycles to shrink grain. For clarity, the hardness test (diamond cone 150kg type, not superficial) is done after resting in the freezer. I'm not looking for industrial warp prevention type measures that sacrifice a little hardness. Hopefully all of it was successful, but the side by side test in wood vs. another similar chisel that's known very good will answer that. I realize there are probably a lot more people making knives out of 52100 who are having their eyes cross with the idea of brine quenching, but chisels are a narrower and thicker cross section and it's a better match than knives. Water without even the salt addition will crack the thinner modern plane irons, especially near the keyhole in a stanley plane iron. BTDT. I do better with 52100 if I give it an actual quench before the final quench. I can't think of anything else like that. It has come behaviors that W1 and 26c3 and others don't have. With some luck, a double temper at 400F (long duration) will yield 63 hardness, which is cryo territory on larrin's chart. Cryo steels are generally well thought of in woodworking because there is an improvement in edge stability. they would break bending more easily, but there are specific designs for chisles (mortise chisels and registered chisel types with a fat cross section and short fat tang) that were intended for that. -

I haven't dumped the other anvil yet. It's still on the floor waiting for me [inappropriate language removed]. Given what you guys say, it'll be interesting. The sound and feel is definitely there for high hardness - it's too bad the mark isn't more clear. what's written on this one could match, but there's so little of my mark left due to deep corrosion that an attempt to knock off the outer layer of smooth brown scale did more to take more if it away than to remove scale and show it. The more I use the heavier anvil, though, the more I like it with 4-lb hammer work. It's like having a bigger ford truck vs. a compact 90s toyota pickup. The toyota pickup might last three times as long, but sometimes the load won't fit in it. At my level, i can't complain and in the past have fallen into thinking once I know something "higher end" and more expensive is available, I allow my mind to convince me that I need to eventually move to it, which then becomes quickly. changing to "if it's not good enough, I'll replace it when I wear it out or break it" really cuts down on follow-up purchases.

-

Amateur Chisel Making

Buster Bolster replied to Buster Bolster's topic in Chisels, Gouges, Scissors, etc

Thanks, guys. that's what I thought. The only thing I can recall seeing on video is square ingots heated and run through rollers, and maybe the comments mentioning descaling somewhere in the apparatus that I couldn't see, but I'd imagine on high quality bar, descaling is part of the process and then some kind of surface treatment like pickling. maybe the quality difference so far is just by chance. -

Amateur Chisel Making

Buster Bolster replied to Buster Bolster's topic in Chisels, Gouges, Scissors, etc

I think reasonably, they're not something for me to solve, either. I gather in the old days, the steel would've started with excess carbon or been carbonized to deal with heavy forging, but I'm also working by hand so that heavy heavy forging isn't going to happen, anyway. Drawing out and hammering to width and thickness is enough. I'd be curious if anyone knows enough about how the rod vs. the flats are processed given my sample is fairly small - four or five rod purchases and a bunch of flats, I've only had one purchase of flat stock that was really equivalent to this. So far, O1 and W1 have looked fine in rod, and 115crv3 (tons of graphite or something and wouldn't harden) and this 52100 haven't looked as good. The 115crv3 was no good and the supplier gave me a refund. the 52100 could be inconsequential once I get a few chisels made and handled and tested. if it's just cosmetic, I don't really care. it's problematic in a plane blade only because allying differences that aren't fully dissolved will actually leave different marks on wood - like little lines of a different sheen, probably different wear rates, too. That's not a supposition, but actual experience from the 1095 sample I think I showed earlier - I thought the edge was chipped but it was just the bands of what looked again in that piece, like chromium, leaving little faint stripes on planed wood. In a chisel, it may be no matter. I wonder if the rod is drawn or rolled in a way that the refinement isn't as good as flat bar. -

Amateur Chisel Making

Buster Bolster replied to Buster Bolster's topic in Chisels, Gouges, Scissors, etc

A sliver sawn off of the rod and hardened without any forging looks much the same as far as the shiny bits. So far, I've had 50 or 75 flats with only one showing irregularities. Round bars show some issue with 2 of 4, but it's no issue if the chisel works well. 68 quench hardness is pretty solid given no cryo. Quench tail was at zero F, and quick after the initial quench based on larrin's discussion of cold finishes. That is, freezer makes a measurable difference, but it has to be immediate whereas a delay before nitrogen doesn't reduce the hardness increase much. -

Amateur Chisel Making

Buster Bolster replied to Buster Bolster's topic in Chisels, Gouges, Scissors, etc

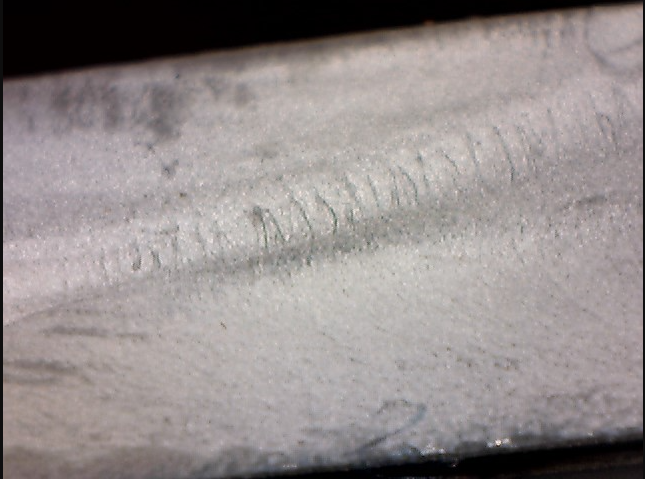

This is just a short (but long due to pictures) follow up after getting 52100 round bar. I get it that 52100 varies a lot in bar form depending on the condition it arrives in. If it's coarse spheroidized, then a fair bit has to be done with it to switch the microstructure to something that will hit high hardness on a regular furnace cycle. I don't have a furnace, and screw around with hand/eye type adjustments to get good hardness without bloating grain. The only round bar I found was from Jantz, which isn't so consumer friendly on small orders ($60 of steel, $40 of shipping), but I can't find much in round bar. It seems like some time ago, it was easier to find round bar 52100 and the flat bar was being rolled by suppliers to cater to the knife folks, and it didn't lend itself to just a quick normalizing and then a sort of regular feel treatment (or furnace schedule). Long story short, I forged a chisel out of this bar, and it came out an inch long, which gave me a piece to cycle. Quench hardness after forging, normalizing, and thermal cycles for a .15" thick sample is 68. The hardness has to be there before temper to make a good chisel. The rest of the nits here can't really be addressed in terms of are they going to affect performance without just making a chisel and testing performance. Testing chisel performance is pretty easy, though - a legitimate woodworker uses a bench chisel pretty much straight in either pushing or malleting. I pick wood harder than would typically used and a mallet that's 50% heavier than I'd use - if the result is good (tired by the time it's time to touch up sharpening, and touch up a brief 30 second to 1 minute process), then the chisel should be fine in use. that's a cross section about 0.15" thick or so. The bright dots are unusual - large grain is either uniformly all that, and I haven't seen something like this in a snapped sample. A closer picture just to confirm that the grain isn't big: I'd guess those spots have something to do with chromium, but they still are strange to see - why wouldn't it be more uniform? I'll have to cut a sliver off of the round bar and heat treat that and break it to confirm that's in the steel, and not something occurring at my hand. the hand held scope is pretty easily fooled by bright things that are grainy into making them look like one shiny bit, so I set the sample in a better (but less flexible) metallurgical scope. The picture is bigger just due to the resolution of the scope. This is steel at the break. I don't have etching solution and don't want to go that far - the round will either make a good chisel relatively easily or it won't, and if it doesn't, I'll move on. The size of the large splotch in the middle is about 10 microns. fortunately, it appears to be an agglomeration of things and not a big solid defect. To compare this 52100, here is a picture of steel that was bar and that I'd normalized, cycled and hardened using an induction forge to make gravers to stitch rasp teeth. These came out of the quench 68/69. Compare this to picture 2. The last sample is buderus 52100. I have no idea where the jantz stuff comes from. There's nothing involved forge wise for the last picture - it was just quarter flat stock cut into gravers, so the treatment of it was all thermal. Since I don't have a furnace, I can't answer this question, but maybe someone else can - if that's chromium in those splotches that's poorly dispersed, is a regular furnace normalization actually going to disperse that evenly and make it disappear? I think this is a hard question to answer unless you've seen it and done it. Reading this makes it look tedious, but I'm already heat treating by hand and eye. if there is a problem with the steel and I am heat treating by hand and eye, I'm sure everyone will immediately assign it to the heat treating. It's usually the steel in my case if there's a problem. chisels don't benefit much from alloying because they don't wear due to abrasion, they wear due to distortion of the edge in use. So far, the best chisels I've made in use are 64 hardness 26c3. They seem to hold together practically forever. here's what 26c3 looks like snapped, same quench hardness, and holds maybe some little bit more after tempering and though 52100 is "more hardenable" getting 26c3 right is a lot easier. If it sold in round bar, I wouldn't be talking about other steels for chisels. -

Not much on the review of this book above. I bought the book shortly after it came out, but have generally used simple steels for knives sometimes, but more often tools. Larrin's website is a better resource than the book, in my opinion, and I don't know which is better if someone wants to support him - but I would guess patreon gets more of the same dollars to him as a %. A lot of things in the book center around really high temp soak steels and things like carbide coarsening and if you're a reader and seldom a doer, it gives something to read end to end, but learning to heat treat is easier with back and forth reference between attempts to improve what you're actually doing in front of you in the shop. When it came out, and maybe it's still the case, it was inexpensive, though. It looks like it may be a few dollars more now or maybe I'm just not remembering that it was the same 3 years ago. The level of information in it is thorough enough that it's not summary leaving you asking a lot of questions, but it's also not like reading a research paper on steel where you're left feeling like you need some other references to decipher what's in it.

-

Amateur Chisel Making

Buster Bolster replied to Buster Bolster's topic in Chisels, Gouges, Scissors, etc

Hi, David - I haven't been accurate enough in the past to get the tang drawn to greater thickness by hammering, but it's been quite some time and it's possible I could do it now. the other thing that's popped up is 125cr1 showed up at New Jersey Steel Baron, and it should be similar to 26c3, but I can buy it in 3/8 bar stock, and that's fine for anything I'd make tang wise. I think in the past, I didn't want to spread out the rest of the chisel vs. just tapering lower half or a little more of the chisel toward the bevel, but I'd be fine hammering the whole length to thickness from thicker flat stock now - which just leaves the bolster still being forge welded. obviously, it's one of two things. On a chisel with a ferrule, it's stopping the handle but if it were to fail and stretch down the tang a little but, the brass tube would stop the tang from going in further at some point. But on the earlier styles, it's the only thing that keeps the tang from eventually splitting the handle. Point with that being I leave the bolster a bit big out of caution, I guess, but I haven't ever proven that's needed and if a bolster has failed, it fails to forge weld. I've never had one break after the weld is good, but if it's formed on and the weld doesn't take, they're no good - and it's apparent immediately. Forging the chisel out of round stock alleviates that I guillotine the bar in front of and behind the bolster section and then grind and file and the bolster can be thinner, which looks nicer. 52100 is a bit of a trick. I can go into this on another post sometime or perhaps make a video of doing it, but I think a temperature overshot for a short duration is a better bet than trying to soak it. I am about to forge 52100 bar. I'll snap samples and let you know what I can get, but it was the one steel that vexed me when I first started - it tolerates more short duration high heat than you'd expect and needs it to hit high hardness. it's this process of testing how high and for how long to get grain to bloat that gets you where you're comfortable not bloating the grain but getting high hardness. Little short bits of it are nice for this, of course, because you can manipulate heat level with them easier and they're quick to cut off of a bar or whatever else, hammer out - whatever you want, and then easy to break in a vise. If 52100 is hard to break after quench, really at all, it's got more room to go before things turn sideways. 80crv2 is a little like this - it really needs a decent dose whereas 1084 tolerates almost nothing and bloats quickly - like in 10-15 seconds of overheating. doing the exact same thing with 26c3 results in a superb chisel at high hardness, and with thermal cycles preceding the quench, snapped grain is half the size of a commercial vintage file cross section. I think 26c3 is ideal for this method - it responds well but the carbides block grain growth a little bit. 52100 is harder because you really have to push it more to get the carbon out into solution to get high hardness. it's just torture to use in woodworking tools if it retains a lot of toughness and holds on to a deflecting edge. And when it's got subpar hardness or issues with retained austenite, the edge just deflects easily. For gravers this past year (to stitch rasp teeth), I saw 69 hardness out of the quench with 52100 and 64 after a solid double temper at 390F. it behaves like a less tough steel when it's successfully done that way, the fine edge taking is better and it won't roll. Rolling is toxic in woodworking tools. Even if it's failure by rolling. I think it would be very hard to nail with a longer duration soak, even using a muffle and thermocouple. this method I'm talking about was probably done regularly 175 years ago, but it's frowned upon now. I just fail to see the reason as once you get the process down for finding the bloat point and doing some samples inside of it, the whole process takes a total of about an hour and you need to do it once in a lifetime for each steel. -

How to safely ask curmudgeons for advice?

Buster Bolster replied to Glenn's topic in Everything Else

Someone who pointed me in the right direction a long time ago - sort of "you can do better, and don't think you can't without proving it" got a fair bit of bad press from question askers on woodworking boards. I'm sure he rubbed people the wrong way elsewhere, but I would consider him as reliable of a source of general advice and some very deep specific advice in certain areas. In short, his sometimes disagreeable or dismissive manner - or perceived to be that is from two things: 1) people who have not made or really learned anything of note asking for advice, and then wanting to argue, especially if they come up with "my opinion is just as valid as yours" - all too common. 2) people who ask for advice and then draw it out endlessly without letting you know they're probably not going to use the advice and tell you later they didn't. There aren't many areas I can give advice that you can't just find better elsewhere, but in the few that I can give good advice, I've started to grow a curmudgeon crust. In some topics, the demand for gobs of information is big from the start and the chance of complete follow through is probably <5%. I wrote some articles about things in the past and a red flag is when someone wants to know something, you send them an article link, or links to other references to look at, and they won't actually read them because they think it's a waste of time. it's too bad we all don't have a number below our name that conveys our intent to each other with a color to say what results we're looking for. Green and 100% for someone who is going to take information you give them and go do their absolute best to use it and down from there, and so on. -

amateur chisel maker, and on woodworking boards where I started, i took a lot of grief from people who liked the chisels I was making before I managed to figure out how to forge weld on a bolster (not a blacksmith or that wouldn't have taken as much creativity). After not hearing it for a while, one of the guys I made chisels for said "you need to start making and selling chisels instead of getting so wrapped up in getting the bolsters just the way you want". My real name is Dave.

-

Amateur Chisel Making

Buster Bolster replied to Buster Bolster's topic in Chisels, Gouges, Scissors, etc

I think there may be some cases where aesthetics can't be handled at the same time as the functional parts. On chisels, I have some aesthetic wants, but none of them are tuxedo t-shirt in nature where they don't serve a real purpose. Put differently, I'll chase aesthetics when they can be done along with the functional, and sometimes they can't and I don't care to chase them then. the heat treat stuff has an off shot. I've got methods to figure out how to do heat treat hand and eye with simpler steels, how to control grain size, and dial in hardness. Someone told me they snapped samples in the old days to grade batches, so I started doing that and taking pictures - once you are consistent, everything looks relatively small. If that shows up, it's W1 magnified at 50x, or to scale it, the sample is .14" thick. Since I'm just starting to draw out and forge chisels, there's some hesitance on my part as to whether or not I can get the grain back and get decent toughness. Since some of the chisels draw out longer than I need them, it gives an opportunity to use the cut off end length to test things. to get a handle on this takes a $15 handheld scope and about a 10 minute process to go from forging to normalizing to thermal cycles to heat and quench. If I had three samples, I'd intentionally overshoot them to see how much grain growth there is, what it looks like to get it and then that's sort of the end of it. Patterns of behavior emerge and then you don't have to "remember how to do 10 different steels 10 different ways" but rather you find some to lump together. 1095 and W1 and W2 (no surprise) seem to like about the same thing. 26c3 is slightly more tolerant of pushing the heat briefly before quench and 1084 is less. I think this is very very easy to learn to do, but it's limiting to some extent. At any rate, a little diligence with these quick trials answers a question for now - I *really* like drawing the steel out and forging these chisels instead of just tapering flat stock and forging on a bolster. It'd be a real shame if in trials against my other chisels and known standards if they don't perform as well. I can't live with that if it happens - as in life with it and ignore it. don't worry - I'm running out of new topical material to post long posts about. I'll lay around in the long grass in case anyone wants to get really good at heat treating hand and eye specifically because it either fits their workflow like it does for me, or if they really enjoy it and want the challenge. And that's before saying there could be three other people on here 10 times better at it than I am and I just don't know it yet because I'm new. this sample tested 68 hardness out of a brine quench, by the way. Another little learned thing after starting to forge. No round 26c3 forces me to look at other steels and W1 really seems to like brine better (I thought brine was kind of a mortal sin, but haven't cracked anything chisel shaped yet - I'd be much less confident about a thin tall knife), so I'm learning things that I didn't expect to learn.