Paul Kin

Members-

Posts

146 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Paul Kin

-

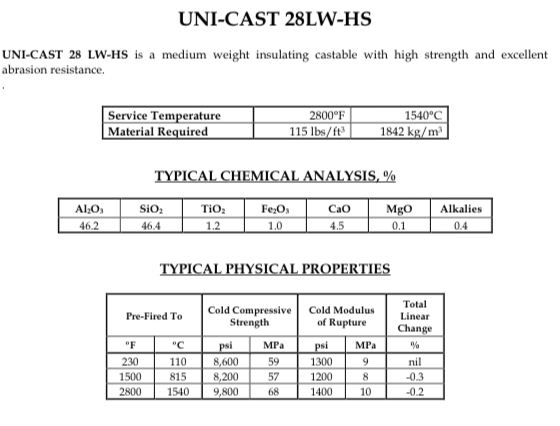

Ok here is the specs on the URC insulating stuff. It seems like a good product. Not quiet what KOL 30 is but at more then $25 a bag less then the KOL, its a fairly similar product is it not?

-

Thats actually a really good point Thomas. I completely overlooked that possibility.

-

Ahh I knew you'd drop in Frosty! By the way, I was in no way, shape, or form being mean. If you took it as meanness, I apologize! Sorta... (I have been in so much pain that T3’s only give 30-40 mins of slight relief, and its been 24/7 for over a year now) I never ever intend to be mean, I do anger far to easily as of late, but Ive decided recently that if anyone takes offence to things I say then “meh”. That is all. Anyways! What I meant by that little “jab” if you will, is that every time I have posted in the past, you come in real hot until I explain what I meant. Then, we tend to understand each other and be civil. I still respect you and your opinion very much! And I mean you no offence whatsoever. I am simply getting very bored with my forced time off and its starting to show... I have 6+ months of this to go. Likely more then a year by the sounds of it. Ok, back to it! I completely understand the tried and true methods and materials. It makes sense, I mean why spend money and time on the unknown?? Thats how we got to the moon right? Never try whats unknown! Altho, maybe thats not so... Again, not trying to offend. All Im saying is, there are other, very similar products out there that should work just as well and be a bit cheaper. KOL may be fairly inexpensive to you guys but its near $200 a bag by the time it gets to my town. Another thing, in reality, how much difference does insulating vs dense castable REALLY make? I have been using both for over a year now in several forges and have really seen a drastic difference... maybe its just me being a skeptic though. I do tend to question anything and everything that doesnt have hard scientific evidence. What I’m trying to do is find other affordable options for Canadians of all budget levels. And Americans of course. But if a rich man can barely afford it in Canada, its just pennies to a poor man in America . Sorry for the long responses. As I mentioned, I have excessive amounts of time right now! Haha! Watch who you poke fun of! I could send my condolences for recent events in the USA as well!

-

I guess what I mean is I havent had luck finding it in Canada yet.

-

Urc should be readily available down there though no?? I was told its all made over there... theres another refractory I have readily available called versagun abr. Its a mizzou replacement. Made by the same company as Kastolite. I havent had luck finding bubble alumina yet though...

-

This could be a fun ride! I know how much you guys LOVE innovation!! BUT, I have been told by the doc that I am in much worse shape then I had thought, and I am not allowed to work for at least the next 6 months. If Im lucky! So.... Im starting to get bored.... Im allowed a little time in the blacksmith shop each day but have to shut it down as soon as I feel the slightest bit sore, typically 1-2 hrs at most. Its keeping me sane at least. Sort of. Well.. maybe not. Anyway, that leaves 16-18 waking hours to do research! Woohoo! Ok, sorry, this is getting long winded already. I should start a blog... oops! Back to it! Ok so I have been researching refractories. There are soooo many out there! Lets just stick to one brand for now. URC. They have something called uni-cast LC94. This stuff would put mizzou to shame. In theory. It can handle 3300° and has 93% alumina! (How much is to much btw??) would this stuff not be great for ribbon burners and forge liners? I know its a dense castable, but so is mizzou. Then theres the unicast LC65SR. High alumina, thermal shock resistant. Uni-cast 28 LW-HS, 2800° insulating castable. Close to a substitute for KOL 30 LI Plus as far as I can tell... And theres many, many more! My big question is, why are we so married to KOL 30? Dont get me wrong! I love the stuff! Built several forges with it this year already (before I found out how bad my back really is). But with so many other seemingly great options, why are we so stuck on it? Is someone being paid to push it?? Kidding of course! Anyways... maybe this is me just going stir crazy. Its amazing how little a person sleeps when they arent doing any physical work. Frosty, read it all over if you feel the need to be ummm somewhat less then easy going! NO OFFENCE!! Your reading and my explanations dont always work hand in hand .And thats ok! But I promise you theres nothing really crazy in here if you just read it over! I very much hold your opinions in the highest regard. That is a fact. Thanks for looking!

-

So Im a little new to small scale hydraulics like presses and such. I have been working on heavy machinery for my whole life but thats a whole other ball game. Im looking to get 12 tons on 120v. According to the online calculators I have been using, a 10.6 gpm 2 stage pump that puts out 3000 psi in high pressure paired with a 3.5” bore cylinder rated for 3000 psi should get me 4.2”/second in low pressure and hit just over 12 ton in high pressure... does this sound right? Now, the pump I am looking at calls for 5hp. Does this mean 5hp from a gas engine? In which case a 3hp electric should do no?? Please let me know if any of this is even close!! Thanks!

-

[urgent] lining up the burner in optimal position

Paul Kin replied to apexmateria's topic in Gas Forges

Im not going to comment on the forge plans as you have the best on the forum giving you advice already (hint: listen to them!) Frosty’s brain seems to work in numbers very well from all the stuff of his that I’ve read so I cant say any more then him, or the others, on presses. What I can give you though is my own experience. With the forge, once again, listen to these guys! The press idea, well I had the same thought as you with the wood splitter. I built one for under $300 CAD. It works.... as long as you know its limitations. Its “6 tons” (probably measured at the splitter edge) so its VERY under powered for heavy work. However! It does 10 times what I can do by hand with my 5 pound straight peen on my low anvil! So it most certainly will save your body if you are on a budget and plan to do slightly heavier work. I use it for drawing out 1-1/8” 1080 hex bar. I know a 12 ton forging press would more than triple my efficiency, but I aint got no $5000 kickin around to buy one, and hardly have time to forge these days let alone design and build another toy for the shop... so if that is what you want to go with, it will work. Just a lot slower then a real press. -

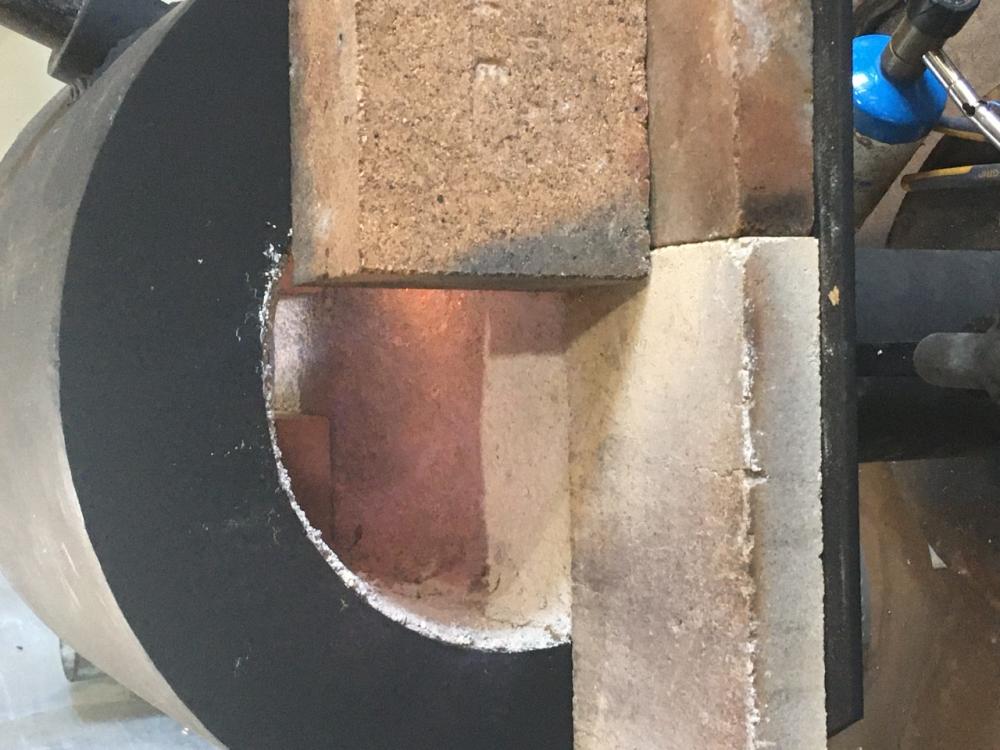

Well this thing is pretty sweet if I do say so myself! Its mesmerizing just to watch. Theres a near perfect vortex of flame swirling in the middle. Almost hypnotizing... as if its calling you to join it.. become one with the gentle, caressing flame.. Anyway! It works really well. Once up to heat, you have a full 8”x9” floor thats very evenly heated. This T burner worked out well too. I can turn the regulator down to 3/4-1 turn from closed and maintain about 1500° for heat treating. I tested it by doing a couple normalizing cycles on a knife. I need to get a new gauge but it looks to be at around 5 psi. I can do my forging at about 10 psi. It is only about 225 cu/in of course so the burner doesnt have to work very hard at all. Weird thing is though, it doesnt sputter almost at all at even the lowest psi. It does a bit at like 1/4 turn from off on the regulator... but it just runs so smooth. Im not sure why this one works so well compared to any other one Ive ever made. Any insights as to whats up there??? Id love to be able to repeat this. Heres some pics though! I couldnt catch the swirl with a picture unfortunately though... That last one you can see theres certainly a hot spot but it wasnt up to heat yet. Once I get going I always forget to take my phone out and get more pictures... oh well! All in all I am very happy with this one!

-

Well its lined! just finished this afternoon. I will probably fire it on sunday and start the drying then. But here it is so far: The back “porch” is line for a reason. I have a plan for some reversible doors so I can add 2.5” floor space if needed. But thats for another day. Cant wait to fire it up!

-

Sounds like you have it figured out! These guys know their stuff when it comes to forges, much more then me. Im still going to follow though cause it sounds like this will get interesting

-

Thatll be a nice size forge for big work! You might need a 1” burner though? If I understand your dimensions right, even if you filled it half way up for the floor so its a half circle, youd be at just about 400 cu/in no? Anyway, Mikey and Buzzkill know so much more then me about these things its not even funny! So Id go with what they say over anything. This is just something I noticed and may or may not be correct!

-

Haha same here! My dad has a lathe so I usually go make a few. Its about $20 in parts including the mig tip and adaptor then I ask $5 for my time. I hear ya there! If I have to start making NARBs, my time would be worth a little more! Thanks! I have a handful of my earlier ones spread throughout my neighbourhood getting tested out. I am just getting to the point that I feel confident enough to sell them. Thats what those 2 started billets are for! This guy has been asking to buy axes for months. So hes up next!

-

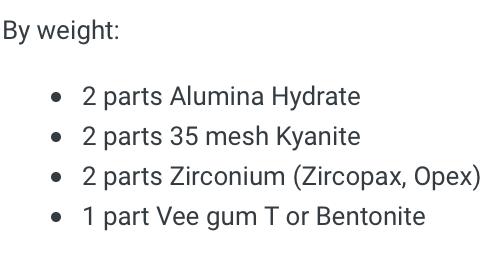

Question! This is the most recent formula Ive found for the diy ITC-100 on these forums: Is this still the case? If so, a person can make it very cheaply in comparison... thats why Im hesitant on buying the stuff. Just seems to easy and cheap no??? And if this is the case, why is ITC so expensive?

-

That would be a good way to go Jealdi. Would be the easiest most effective solution for you by the sounds of it! Plus gotta love the buy, pick up, hook up, start hammering proccess! Thomas is so right its not even funny! If I were able to be working full time I wouldnt have the time to build these things. Unless I simply stopped sleeping! Also, that was the case with my grandparents on my dads side Thomas. Never met my grampa. They were a mining family. Worked almost every mine in the area here. My dad and his siblings grew up playing in the mines even!

-

T burners are great! I cant even count how many I have built this year... every time I tell a friend to just look up and build a T burner, a few days later I always get “uhhh can you just build me one?” But thats ok cause I like buildin stuff n things! I will eventually build a NARB... I just dont fully understand em yet and havent had a chance to experiment. But all Ive read about them they really seem amazing. Heres the axe style Im making and sort of basing this forge off! The bearded one on the right is mine, the left one with the burnt handle I won from Alecs 4 weeks of forging And then theres the 2 billets up top I started recently. Nothin wrong with buying a forge Jealdi. Just make sure you buy a quality one... those ebay ones are 1” of raw kaowool. Not very good.

-

Ahh that makes sense... I always have friday afternoons after physiotherapy to do my running around. Which is also nice cause friday afternoons is beer time for most shops here and the are very friendly then With your HVAC guy make sure you ask about 2600° blanket! Id bet he carries more lower temp stuff, but I could be wrong! Thomas has a good point with the helium tanks. Also, I feel like 6” might be a little short unless your building a mini forge. My forge is 9” and thats as short as I feel I can get away with. Though a 6” forge would probably work well for hooks and such I suppose. Tanks are really nice because you can cut your openings the size you need and leave the rounded lips to cover the end of the insulation. No welding needed. Can bolt on legs, burner holder (aka plumbing floor flange). Aw heck you could even use nuts, washers, and longer bolts for the legs! Could literally do it all with hand tools.

-

Haha you got it! But even a propane tank is way thicker then you need. Do you have a local welding/fab shop? They may seem intimidating, rough n gruff, but usually thats just on the outside! Ive worked with/in most of our welding shops and they are all really nice guys. Tell them your building a forge. Welders love that! Around here anyway haha. Im sure they will help you find what you need.

-

Jealdi just be careful! Propane tanks are not safe to cut up even if you think they are empty. I have a way to ensure they are empty but its also not safe! Sorry I dont go into detail, its just not safe JHCC those doors are epic!! I think Im going to do a little replanning on my doors! I dont need that cool a back door but it would be very nice to have the fronts like that... Thomas thats pretty neat! Would make a cool lawn ornament/fire breathing shop sign if it doesnt sink into the ground

-

Haha good point Thomas! Team striking is already effective enough that it really probably doesnt need any innovation to mess it all up! Also a good point Frosty! The main reason it is taking me so long to read your NARB thread Jealdi, thanks! But its not necessarily “my” design. Theres a lot of talk about the mail box or D shape forges. Theres more good then bad in the half circle design in my opinion anyways. You get the widest floor possible without having to heat extra space. The material is, as Frosty stated, heavier than necessary. But I use what I can find free in the scrap bin at work. My boss also runs a logging outfit so heavy scrap steel is a plenty! So to answer your question directly, I fabricated the shell from a deactivated 100lb propane tank, 1/4” plate for the faces, 4” tubing for the stand. Im going to say this now, THERES NO SAFE WAY TO CUT A PROPANE TANK!! There. So I stupidly cut it up of course with methods I will not share To avoid wasting to much durablanket I simply measured 3.5” past center on the cylinder and welded in the floor plate. Thatll give me 3” of blanket and 1/2” of Kastolite for the floor and put the floor right in the center of the circle, the widest part, for the widest floor possible. Make sense? I see a really cool dragons breath breathing sculpture/forge thingy there Thomas! Just needs a dragon inspired paint job!

-

you guys!! Im not laughing at any of you. This thread just cracks me up! I think I will just let this continue and start a new thread when the build continues! I was really hoping to have it done already, but you know... life happens. So keep on sharing if you guys want! Ill start a new, more focused thread Also, as crazy as that sounds Thomas, I actually believe it! I have had sneezes cripple me for a day due to my disk problem. They are a very powerful move. If only we could harness that power while team striking...

-

Well I hope he found his niche market! Its a great, rewarding job. If he were a we bit closer Id send him customers! I often send customers to other local mills when I cant keep up. All our local wood is spruce/pine. My boss brings the fir in from way out of town. Vanderhoof to be more precise. So I also work with a lot of spruce! Fun fact, spruce is stronger than doug fir per weight and equal grade. Fir is much heavier though so you need much larger spruce. Haha yes back to the forge! Nothing wrong with a little sidetrack now and again!

-

Thanks and good to know metalguy! It just so happens I have some hooks on consignment with a local potter. I will ask her! Kiln shelves totally slipped my mind for some reason. As for the burner, I think I may just go strait to the standard T burner for this forge... I just dont feel confident to build a proper NARB yet. And now that I know how to tune the T burners well, Im running just 1 of the 2 burners in my big 500+/- cu/inch forge at a high forging temp and not even at 15 psi! 3” insulation in that forge also so that probably helps. So this new forge at about 250 cu/in should easily hit welding temps and be very efficient as well.

-

Oh I see! Still, you know what its about and the work thats involved. I have a lot of timber framers for customers so for the most part, a 6x6 timber is the smallest thing I mill. Theres all the 1” and 2” side lumber of course but thats almost never a lone order. 8x12 doug fir is very common. As well as 8x8. The occasional 10x10, even a big order of 10x16 beams once! That was something... Woodmizers are so wonderful to work with. If you take your time, you can cut perfectly square cornered beams every time. Like we are talking less then 1/2° out of square. That mill can produce some absolutely beautiful stuff! Thats to bad it never went big for him.. it is a hard game. Im very lucky to be right on the highway between 2 towns and the boss has a logging show so the logs are easy to come by. 2 huge factors in our success. Hopefully Mike still at least has the mill! Its an unexplainable feeling to get to work, hop out of your truck, and get a big wif of fresh sawdust from the day before.... almost an antidepressant really.

-

Holy cow Frosty is there anything you havent done?!? You sound like some of the old timers around here. Ive worked with a lot of em cause I spent my first 10 working years trade hopping. I Learned more in my first few years then Ive learnt in all my school years put together! And met a lot of wise old men. Honestly where most of my learning came from. And still is infact! No offence! Not calling you guys old! Head saws are great if you want some real production! My neighbour, who actually founded my area, has one. Hes gone now unfortunately but Im good friends with his son. But that thing would buz through a log faster then you can spit. Was also a death trap. If you didnt work faster then it, youd be working right beside the blade! Sounds like you guys had a really good setup though! I actually have a good system but theres always slabs and big timbers to move around. Its a WM LT70 full hydraulic w/ electric motor and board return. Green chain infeed and conveyer to feed the finished peices onto the green chain out feed. Wheel loader to feed and forklift to take away. Sounds perfect right?! No lifting! Well in a perfect world, yes... But I still have to lift well over my own weight several times a day. Just how it goes! I still love it and want to continue doing it. Just have to start working smarter, which I actually already do believe it or not! Boy if they end up being able to replace disks, Im in! I have a very thorough understanding of how it all works. My physio is great about explaining whats going on with diagrams. She believes my core should eventually be able to compensate. Just have to get there... Oh if only that were possible Frosty! Even if I could go back 10 years... Thomas, thats a very good way to look at it! Whats the point in life if your not going to live?! Ahh that was a wise move on their part! Over the last few years I have really smartened up. But I used to be a brute force kinda guy. Probly the biggest reason I am where I am.