-

Posts

29 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by matthewfromers

-

Hello to you all! I've realize this little new friend from a forge weld test, and it look quite good to use! I will spend much more time sharpening it with some stone!

-

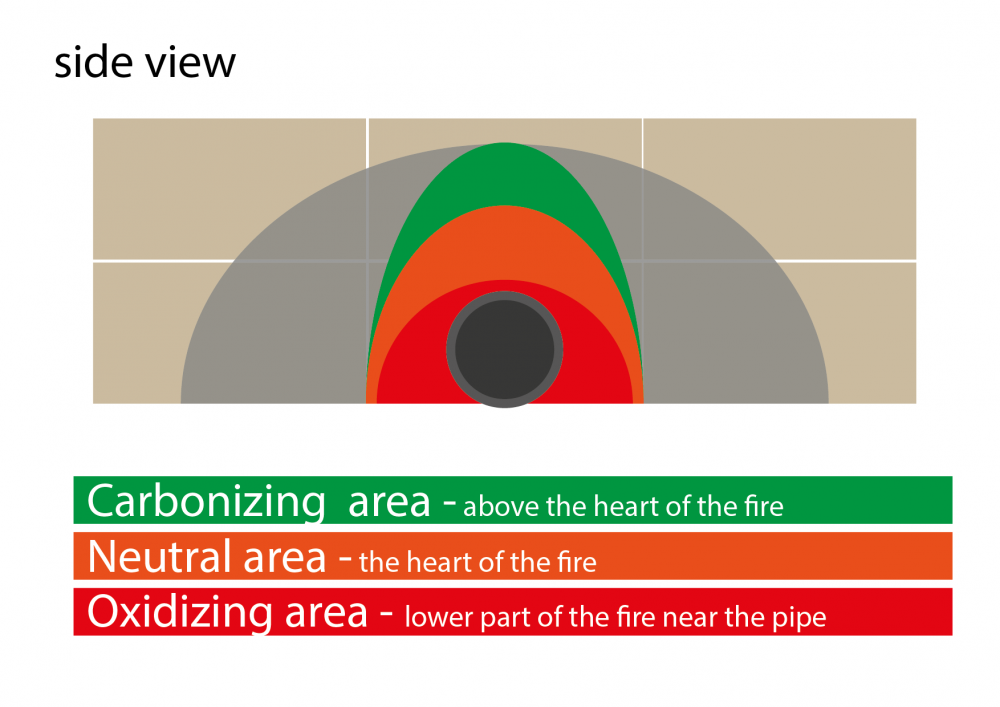

Thank you very much Jlp! I made a little outline based on what you told me, to get a clearer idea of the concept, to see if I understood the above and why I like to do drawings Can the areas I highlighted be considered consistent? Considering of course that they can change based on how much air is blown inside. Thanks for your support, Matthew

-

Dear Jlp, regarding the bellows, I chose to use all reclaimed woods that I already had and I was not very attentive to the traditional method of construction. I made something definitely solid but certainly not original. For the seal on the piston I used an old soft carpet that resembles a fur coat and keeps it greased with Vaseline! It works very well as a system! I thank you for the suggestions and I will try to better test my results, for now, a small first experiment is this spear plane that I have finished and I must say, that there are no traces of delamination and cuts the hair of the arm very well!

-

Dear Jlp, I really appreciated your explanation is very clear and I will treasure it for the next times! I'm trying to learn a lot what the forge "expresses" during the runs. The color of the flames, the type of sparks, the noises. In addition to being all very fascinating it is very important, in my opinion, to become familiar with the forge and bellows. The bellows, among other things, allow me a lot of air and flow control. Place some photos. I feel very good about it and I think that this guy (fuigo Japanese), increases the feeling with the fire. It is very difficult for me to understand the color of the package when it is well covered with coal. I'm always afraid of overheating and I often try to control it. Thanks again! Matthew

-

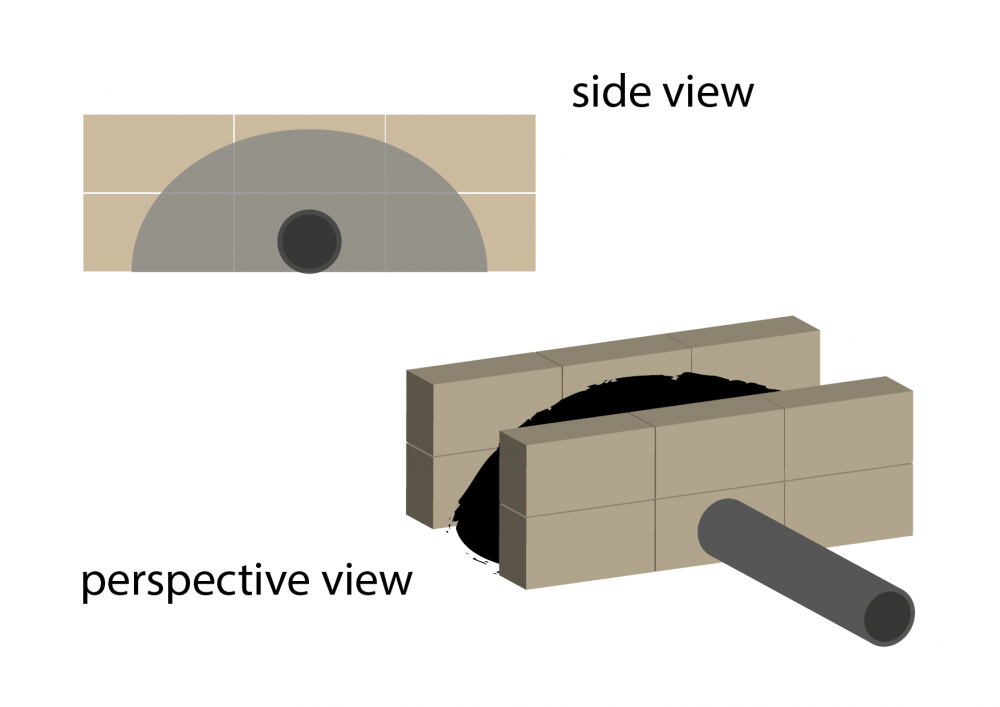

very kind Thomas, I'm trying to figure out how to control the atmosphere of my coal forge (side turkeye, Japanese style) trying to keep the packets above the air inlet with a good quantity of pieces of coal on top to cover the all. Any other advice about it? I really appreciate the support from you all. Many thanks to all. Matthew

-

No, it doesn't!

-

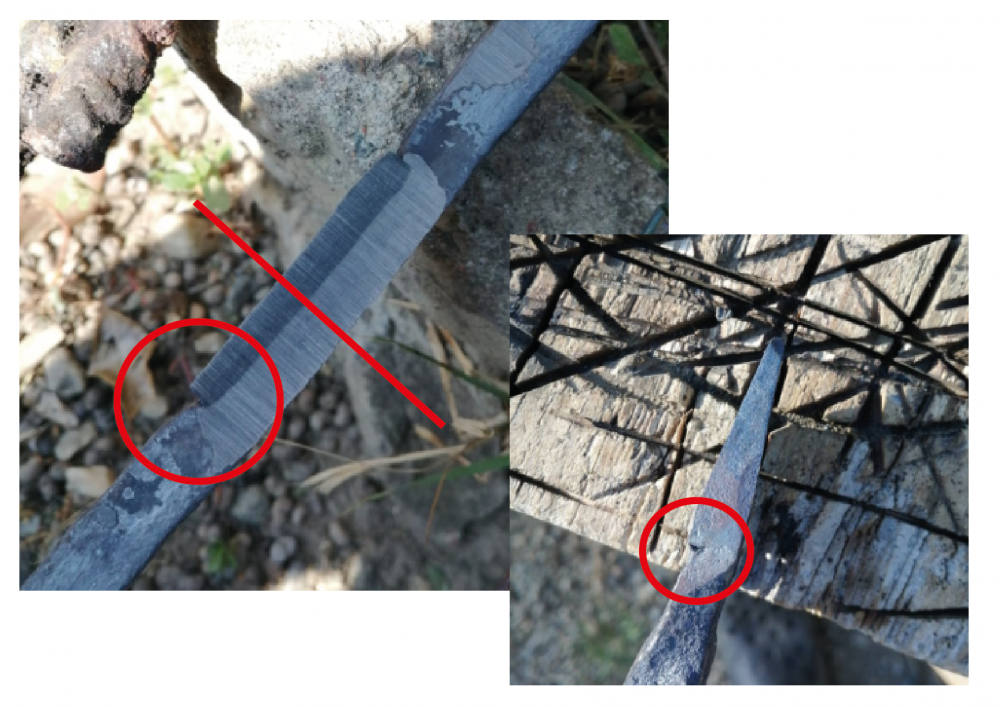

There's a little line between the two pieces of w1, I didn't find out anything about that on line, it looks like good forge welding and there's not any sign of delamination. It is normal?

-

Wooow it look great! It's a full flat grind with a microbevel? Amazing work! Love the handle!

-

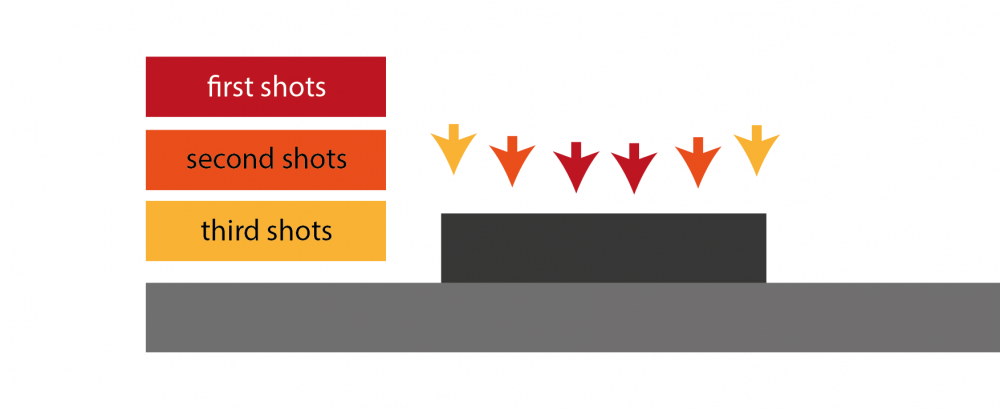

Hello guys! And thanks for all your advice! I see that I've a lot of work about forge welding! On saturday I run my forge and japanese bellow with the purpose to make some other forge welding, after all you advice. First of all I've choose more compatible material w1 with iron and 1070 with iron. The result this time are for shure better and I didn't have any delamination. I show my result: I'm happy about that, I guess that I've learn a little something more! The "scarf fact" open up a world to me and I'm very happy about that! In one of the forge weld I stumbled in some cracked small area, almost certainly caused by the excessive temperature, (the packet coming out of the forge threw out little stars), and I think that this problem depended precisely on this fact. Should I learn to recognize the temperature just below the melting temperature and weld to it, to avoid this? Another question that intrigued me a lot was, how long can a package be for effective welding? It could be possible (using hammer and anvil) forge weld at 6 inches x 1.5 inches? I'd like to get a material ready to be turned into a knife. Thanks again to you all, have a nice day! Matthew

-

Yes sorry, my fault! Vercelli! I'm living in a near small plase near by Vercelli! Woah! Amazing trip anyway! Vercelli it's really famous for the rice coultivation!

-

Oh Fabriano! I know that area! I'm living in Cercelli north-west of Italy it's between Turin and Milan. And il looks like Iowa. ahahahah Thanks for the support man!

-

Dear anvil, do you mean some thing like that in your forge process (in this case of course): Do you mean something like this Frosty? Yes I think that could be a risk! I'll try! Thanks you all for the support!

-

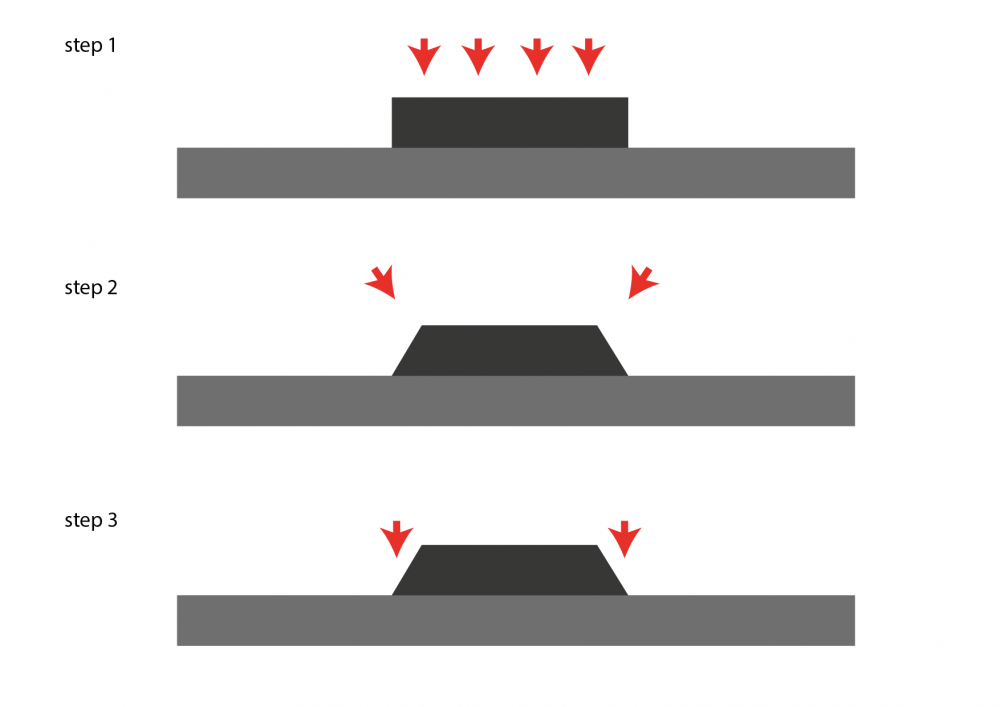

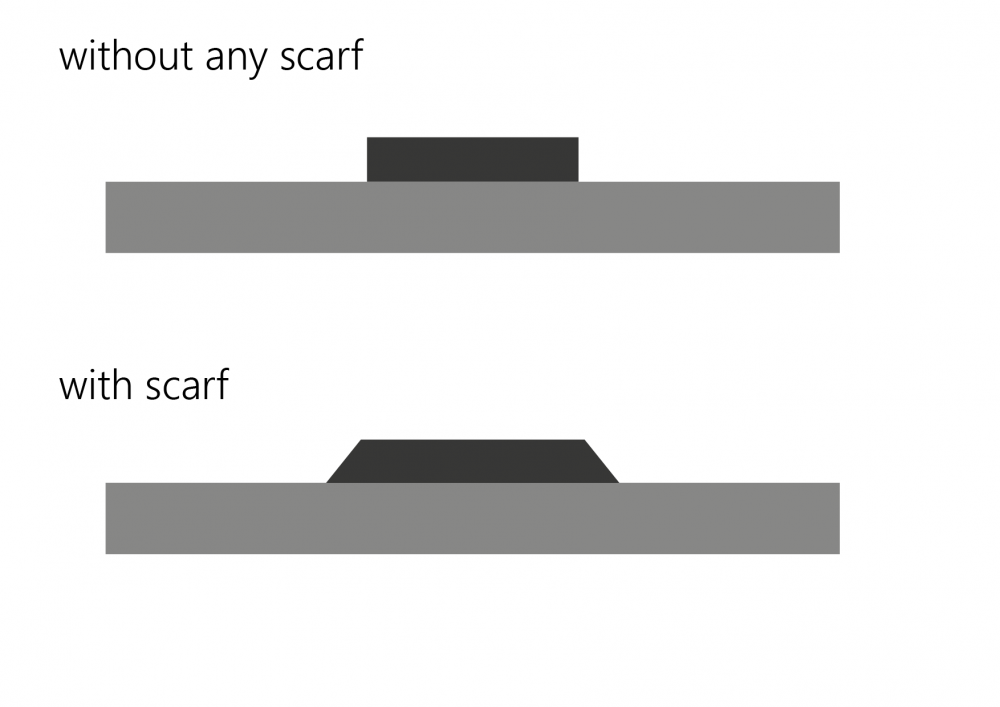

Dear Pnut, I see the pdf and it's really interesting! Thanks for all the advice Dear Jlp, I've understand what a scarf should be! so basicly this is what I've done, weld a piece of w1 on a bar of iron, without any scarf or preparation area, cut in alf and the "transition area" it's, of course still visible. if I have correctly understood how kindly you have exposed me, in my specific case, what I should do is something like this: this should prevent the formation of this "step" or "transition area". Am I right? Thanks you ALL for the post and the knowledge that you 're sharing. Matthew

-

First experience with bloom steel

matthewfromers replied to matthewfromers's topic in Smelting, Melting, Foundry, and Casting

Dear Steve, thank you a lot! I would try to forge it! But for shure I will try with a better and more known starting material! My fault, yes I didn't start from ore, as you said, this cannot be called "bloom" Yes, this should be a most correct term, I've been ispired also from a book of Yoshindo Yoshihara, that describe the process. Thank you all for the support. Matthew -

Show me your blacksmith pets

matthewfromers replied to Glenn's topic in Blacksmithing, General Discussion

-

Dear Jlp, thanks for your support! Unfortunatly I could not understand what you mean for "scarf" in this context. Thanks a lot by the way! Matthew

-

Thanks for your kind reply! So do you suggest me to work the package and proceed with the elongation at a temperature close to the welding temperature? Beyond the orange color? Thanks a lot! Matthew

-

Dear Pnut, don't worry about, I'm very glad for your support and I will for shure try to weld some other material together! And I will keep you informed! As you rigthly said: " it's supposed to be fun ", and, luckily, it is a lot! <3 Matthew

-

Hello! I would like to share some of my favourite knives that I've made! I love to remove material with my belt grinder from plate but also I love to forge! This is made with c70 (1070), leather sheat and home made "micarta". This tiny little one it is a test made from k720 steel (that should by something like 01 I guess). And coated with gun kote! (that I love). This is also made from 1070 with a wood stratification This is an old project (sorry for the bad quality photo), it's old but gold to me, and I still love to carry in my outdoor experience! It is made from w1 steel, and old file. And paracord wrapped. Here one of my first puukko blade! And these, are probably the first stuff that I've made a ton of years ago!

-

If fact the aisi 1060 didn't contain chrome! But probably my truck spring contain some of that I would like to see your tomahawk! I look foward to creare an axe in the same way Matthew

-

Well first of all, good day to you! Last year I started thinking about the idea of getting a material that I can fully feel paternity. After reading through the pages of this forum and learning from other people's experiences, I decided to make a first attempt. I collected some old pieces of iron that I had in an equally old garage. The material from the spark test gave virtually no spark except for a few. So I've made some like a bloomery and run with a lot of charcoal and the pieces of iron. And, of course a lot of air. This is the bloom that I've got! Unfortunatly I was not able to remove the slag from the bottom of the furnace, so it cools down all togheter. My fault. This is one of the pieces that I've cut out from the entire bloom. And his sparking test. And another smal pieces that I've etched. Ant the end I was not able to compact the bloom, a friend of mine, that works in the metallurgical field suggest that probably is because of the chrome in it, (or maybe because I'm not good in compact bloom :P) . Well this was my first try, I think that I've add some carbon in it, I kept the turkeye detached from the bottom of the smelter to allow the material not to oxidize. I think I succeeded. Surely some of you will be able to give me good advice! In future I will try to add some carbon to a certified iron that here in Italy it calls s275jr that it: so no chrome this time! Hope for you all a good day my friend! Matthew

-

The pleasure is all mine to be here! The gentleman in fact advised me to try with 15n20 and 1075 (which we simply call c75 here in Italy). The biggest problem, here, is to find materials of considerable thickness, even normale iron retailers usually have nothing with a higher percentage of carbon than (1040) c40e in Italy. So I've usually find out steel from knife maker supply! Thaks for your reply Pnut.

-

dear pnut, thanks! it was mainly a work of removal, the only part that required forging was to straighten the bar! I quenc it in heated oil, using the gas forge I built and then tempering it in the home oven. No particular sophisticated treatment. I am mainly interested in knives and cutting tools for woodworking, but I would also like to try some other work with iron. I build some machinery like my belt sander, but I don't think it can be valued as a blacksmith job! I will surely cuddle my cat for you! He calls himself Yume and he is a funny guy! Greetings from Italy!

-

Hello! I made this knife from a truck spring, about 1 cm thick! Sharp razor! Homemade micarta handle, screws adapted to make it removable, colored blade with gunkote! Leather sheath! Hope you like it!

.thumb.jpeg.565e815d928c7f7317002fa5ee36aae4.jpeg)

.thumb.jpeg.41c176926a6f6da537872563a97817d2.jpeg)

.thumb.jpeg.c96ed0dd3d3ed55916741907298cabf3.jpeg)

.thumb.jpeg.1888c5f8814bcc092203533ff9d06b85.jpeg)

.thumb.jpeg.a6f169bcf9c0eef5939d4e53095a7c1f.jpeg)