Glenn II

Members-

Posts

61 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Glenn II

-

Blacksmith Sayings Proverbs

Glenn II replied to Borntoolate's topic in Blacksmithing, General Discussion

That was a good read! I can nicely imagine that conversation between Death and a commissioned, yet frightened, Blacksmith. -

Blacksmithing gems and pearls

Glenn II replied to Glenn's topic in Blacksmithing, General Discussion

Very true indeed. At a working history museum I volunteer at, we keep a small supply of items on stock for sale: dinner bell triangles, steak turners, duplex nail swords, and a variety of S hooks. Often times I'll just start by drawing a taper or deburring the end of a freshly snipped piece of 5/16" square stock and someone will ask, "What are you making?" At this point in the process, I really hadn't decided, unless the master Smith has suggested we are currently low on an item. So I tell them, "Anything you want to buy!" Usually get a strange look followed by, "Hey, can you make a such and such?" "Maybe. Never tried." Is my typical response, followed quickly with, "If you have 30 minutes, Let's find out together! If I can't, it cost you nothing but some time." So many "items" involve the same basic methods. Even the most complex concepts draw on the knowledge of previously learned and mastered basics. -

Wood pellets for forge fuel

Glenn II replied to ronwend523's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

Glad I finally found this thread. Saved me a $3.79 headache. Almost bought a bag yesterday when the big box store was out of lump charcoal. Went to a different store and found lump charcoal. Guess it's time to get dressed and head out to the shop... -

Show me your Bottle Openers!

Glenn II replied to Arbalist's topic in Blacksmithing, General Discussion

Update to my post from 12/15/18: Paired the bottle opener and corkscrew with a bottle of JW Cabernet Sauvignon and a six pack of Summit beer. (I guess the wine is like $65US per bottle in my area, but we acquired it randomly and prefer sweet whites like Riesling and Moscato.) Sold the complete package at Auction for $95US. After the contest I overheard a gentleman offer the new owner $25US for just the Corkscrew. The new owner said, "For $25 I'll sell you the bottle of wine, but I just paid $95 for that Corkscrew." Can't believe I made a $95 Corkscrew. Thanks to all of you on IFI that have contributed to my learning of this craft. Now if I can figure out a way to make, market and sell about a dozen per week for the next 50 yrs, I could quit my day job! Glenn II -

Side Note:. Good advice on roberry deferral Frosty, try to be cooperative first. However, I read something the other day that was quite eye opening. Don't hand over your valuables. Throw them as far as you can and run in a safe direction. I had never thought of that before. And of course it's easy to say while never been put in that position.

-

It might not be "something" in and of itself. What I mean is that it could be part of a tool, or other object for that matter, much more complex than a simple flat bar 12" with beveled edges. Something deep inside of something else that few people rarely have seen. For instance, if you found a bracket with the stamp "Ford," you would probably not find many people that would know what it is or belonged to, other than a Ford vehicle, maybe. I definitely don't want to discourage your efforts. Some pieces are easy to distinguish, while others not so much. Best of luck in solving this mystery (not that I was able to help other than to provide some perspective.)

-

Well, I would have thought leaving a nice slice of med rare prime rib, local craft brew, and a generous slice of home made Pecan Pie by the fireplace that maybe i would have seen a 40 lb. bag of lump charcoal? No dice. What did you try Das? Thanks for the Intel Santa Powers.

-

Not exactly sure how to take this, as it is my first Blacksmith Christmas. I'm not sure if I was "Naughty or Nice," but either way I did not receive any Coal for Christmas! It was all I asked for. Although I'm feeling a little disappointed, Santa did leave me a box of Oatmeal Cream Pies and a Butcher Block Brush in my stocking.

-

What did you do in the shop today?

Glenn II replied to Mark Ling's topic in Blacksmithing, General Discussion

Had a busy day in the shop today. Had some good helpers too. Since Christmas hasn't come yet, they weren't wearing their aprons yet. My son made a toasting fork from 1/4"(6mm) mild round stock. He's 10, but did the bending and twisting of the handle. He ran the blower while I hot cut the fork tines and dressed them. We had fun working together to make it, but I believe he liked the testing process more! My daughter made her first split cross from 1/2"(12mm) mild square stock. I helped hold it while she did the hammering. The texture was hammered in with a fencing pliers. Finished the day with my first leaf on a wall hook made from 1/2"(12mm) mild square stock. -

What did you do in the shop today?

Glenn II replied to Mark Ling's topic in Blacksmithing, General Discussion

Made a reverse twisting jig today like I had seen on a link from this site. I'm quite sure I must have around 50 open end adjustable wrenches (crescent wrench.) Took me longer to find 2 of the same size and shape than it did to build the jig. (After the jig was done of course, I found wrenches everywhere I turned in my shop.) Then made a steak turner to test it out. Made from 5/16" 1018 square bar stock, wire brush and olive oil finish. -

I like the color bleed. It really enhances the 3rd dimension (depth) aspect of the project. Like a real tree, it creates a shadowy hint on the inside of the tree. Near the bottom where the branches may be a bit thin, you can see the trunk. Well Done!

-

Common Basic Mistakes That Beginners Should Avoid

Glenn II replied to JHCC's topic in Blacksmithing, General Discussion

I've seen a pair of anvils at an auction that I wouldn't have paid $40 for. They both went to the same gentleman for $385 each. They were around 35-50 pounds, and we're in real bad shape. I figured I was better off hammering on my RR tracks than either of those chunks of metal. I don't remember the brands, but they were definitely abused. -

help construction digging homemade bar

Glenn II replied to angiolino's topic in Blacksmithing, General Discussion

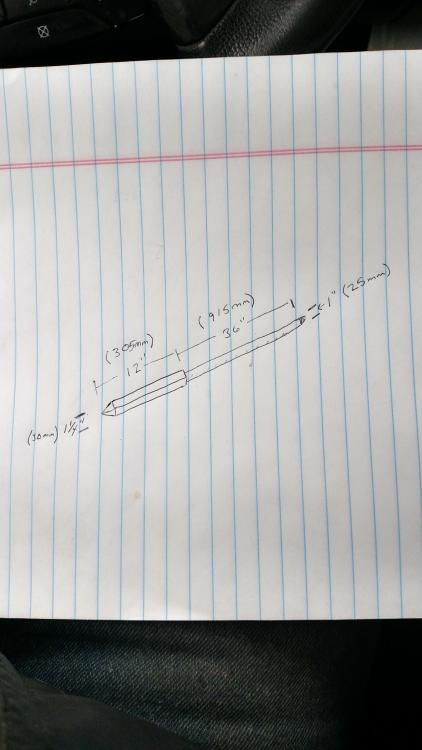

My great grandfather built one using a car axle. He made it in the 1930's, so the car was from the earlier 1900's. Had this shape and dimensions. Square on one end, round on the other with about 1"(25mm) of the round end threaded. You may be able to find something like that? -

Scrounging for blacksmiths 101

Glenn II replied to Glenn's topic in Blacksmithing, General Discussion

Safety First! Lift With Your Legs using proper ergonomics. Plan and clear your path. Carry the load low and avoid twisting motions. If it's too heavy to safely load by yourself, get some help from a friend or mechanical lifting device: hoists, boom crane, forklift, payloader. Also, think about how you plan to unload and move it when you get home... -

What did you do in the shop today?

Glenn II replied to Mark Ling's topic in Blacksmithing, General Discussion

Maybe this will help your confidence JLP... LOL. My first, or rather second actually, split Frederick's Cross. (The first attempt succumbed to a crack when I tried to flatten at too low of temperature.) 1/2" square A36 steel, brass brush finish, coated with SC Johnson paste was, faux suede cord. -

Thomas, I really can't think of anything too clever to come back with, sorry. Thank you for the ribbing! As I'm sure you're aware, Hobart is the brand name of the aprons. But that would have been convenient if it was our last name.

-

What did you do in the shop today?

Glenn II replied to Mark Ling's topic in Blacksmithing, General Discussion

If you get porosity, stop! You cannot weld the pinholes away. They need to be ground out. Welding over the top seems to drive the porosity deeper into the parent metals. In my experience, porosity is usually a gas issue. Check your cone, and difuser, if they are plugged you don't get proper gas coverage. For MIG, I usually run gas at around 25-35 CFH. I was instructed in tech school that it is possible to over apply gas, and create a Venturi type area around the weld pool that contaminates the weld by drawing in atmospheric air. Maintain proper distance from the cone to weld pool to get adequate gas cover. -

Show me your Bottle Openers!

Glenn II replied to Arbalist's topic in Blacksmithing, General Discussion

Made the cork screw a few weeks ago, but trying make a matching bottle opener was a bit difficult. It was a good thing I was low on supply of stock for making hooks, my bin is now we'll supplied! These will be items for sale in a state Auctioneer association contest in a few weeks paired with a bottle of wine and a six pack of local craft beer. -

My kids like to do some Smithing with me in the shop and I needed to get them some aprons to stay clean/safe. I figured since it was so close to Christmas, why waste the easy gift idea? Also figured instead of giving them each an apron, I'd give them their own apron, personalized with their name on it. I wasn't sure the tanning process used on the leather so took precaution to have plenty of ventilation when I burned their names in.

-

What did you do in the shop today?

Glenn II replied to Mark Ling's topic in Blacksmithing, General Discussion

JHCC- I caught a video on YouTube a while ago about how they "fix" neck bridges on guitars. The material is made of either bone or ivory, and after much use the guitar strings will cut through the bridge making the instrument difficult to tune or even play if the damage is severe enough. They file new material of bone or ivory into dust and combine that with super glue to make a paste. They fill in the damaged area, allow to set and cure, then file it back to it's proper shape. In the end, the repair is hardly noticeable. That may be a possible solution to fix your cracked handle. Might be worth a try and possibly easier than replacement of the whole handle. Sort of like bone Bondo. -

Damascus with only hand hammers?

Glenn II replied to JonathonCrow's topic in Blacksmithing, General Discussion

Will W. - Sprint cars are Direct Drive. No Transmission, No Gears (except differential gears in rear end housing), No Clutch. There is a shifter to disengage drive line from engine, but the drive line cannot be re-engaged with engine running. Starting the engine with a starter motor would be like trying to start an old manual transmission vehicle while in gear- you'd burn out the starter motor after a few attempts. When you're talking 850hp and speeds under 100mph, the weight of a 4lb starter motor is not an issue. My apologies for being off topic from the OP, just wanted to correct a minor inaccuracy. -

Frosty- the Roger Degner you mentioned above with the Peter Wrong anvil, would he be in his mid 60s, long gray hair and beard, glasses, retired chief of police? If so I had the pleasure to work an open forge near him recently. An interesting character, great with the visiters at the living history museum, and made some great kettle corn while taking a break. As to the Peter Wrong, "Rog" has it setting in front of the shop. I didn't know it was hollow, as it looks like a rusty old unused anvil. So you can about imagine my amazement when I encouraged my 70# 10 yr old boy to walk up and lift a 300#+ anvil, and he did!

-

What weird animals have been in your shop

Glenn II replied to Glenn's topic in Blacksmithing, General Discussion

Since becoming a member here, I have often thought how cool it would be to visit some of you guys at your shops, hang out, learn some of the trade, make something interesting. But after reading this thread...forget it. However, some of you guys are welcome to visit me any time. The Winters have a fascinating way of keeping the rifraff out of our part of the country. -

What did you do in the shop today?

Glenn II replied to Mark Ling's topic in Blacksmithing, General Discussion

Hey Das, I'm thinking a nice wolf paw print with A's for its claws or maybe a wolf head with "AA" for ears. Might have to be a bit larger punch, but for the bigger pieces. -

We always said in the Fab shop, "If you aren't a good welder, you'll learn how to be a good grinder!"