Glenn II

Members-

Posts

61 -

Joined

-

Last visited

-

What did you do in the shop today?

Glenn II replied to Mark Ling's topic in Blacksmithing, General Discussion

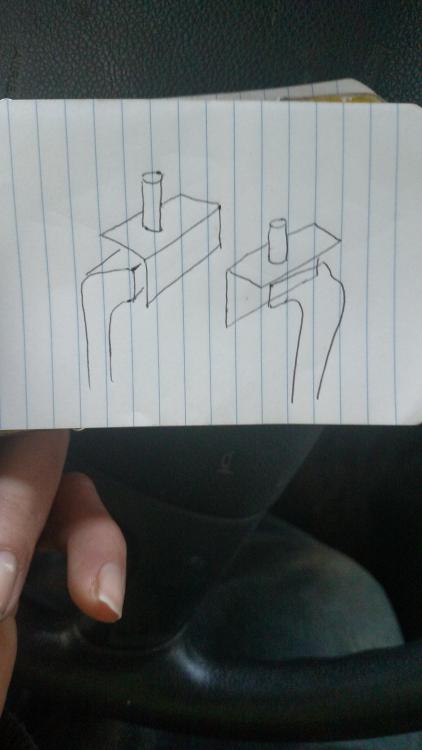

Fowllife: very nice table! I too like to use bending jigs. After about the 3rd different set I had made for a different radius, I saw somewhere (probably on IFI) about this design. Weld your pins on opposing pieces of angle iron. You can place these in your vice jaws and slide them apart for a nearly infinite range of radii. My apologies for the hand drawn pic, but I'm not near my shop. If you use a good heavy angle, and have your vice properly secured, you can bend some pretty stout material. -

What did you do in the shop today?

Glenn II replied to Mark Ling's topic in Blacksmithing, General Discussion

TP, you just gave me a wonderous idea. When I was 4, my mom was late 30s and suffering from scoliosis. She opted for a surgery to implant two 18" SS rods as well as pins and other bits to straighten and support her spine. She would never again take me for a bike ride, or bend down to pick me up, and the many other things a mother does. Bending and twisting to clean a floor or vacuum a car was out of the question and became my duty. Anyhow, she has expressed for many years her desire for cremation, and I always said that'd be fine, but I want the rods. As a child, I felt that the rods stole my mother away. As an adult, I realized that the rods gave my mother many more years of joy with less pain to spend time doing other things like baking, fishing, and much else. I always joked I would make a putter from them, but I never picked up golf. But a nice pair of TONGS would come out perfect from two 1/2"x18" surgical SS rods! -

What did you do in the shop today?

Glenn II replied to Mark Ling's topic in Blacksmithing, General Discussion

Nice cross GFH. You can play around with how much the two cuts "overlap." It will change the dimension of the hole in the middle. -

Show me your Bottle Openers!

Glenn II replied to Arbalist's topic in Blacksmithing, General Discussion

Looks great as always Ausfire! -

I had a truck driver deliver a commercial air handling unit to a job site once. The pallet was screwed down to the trailer bed with some lag bolts as well as straps over the unit. I live in upper Midwest US, this gentleman driver from the southern parts US asked me for a "thumb wre-ench" (2 syllables but smooth). I told him I wasn't sure what that was. He said, "Well, that's one there in yer back pocket idjet. Seen it when you climbed down from the fork truck." Makes sense, I guess, since you operate an open end adjustable wrench (1 syllable) or "crescent wrench" with your thumb.

-

Tungsten Inert Gas (TIG)

-

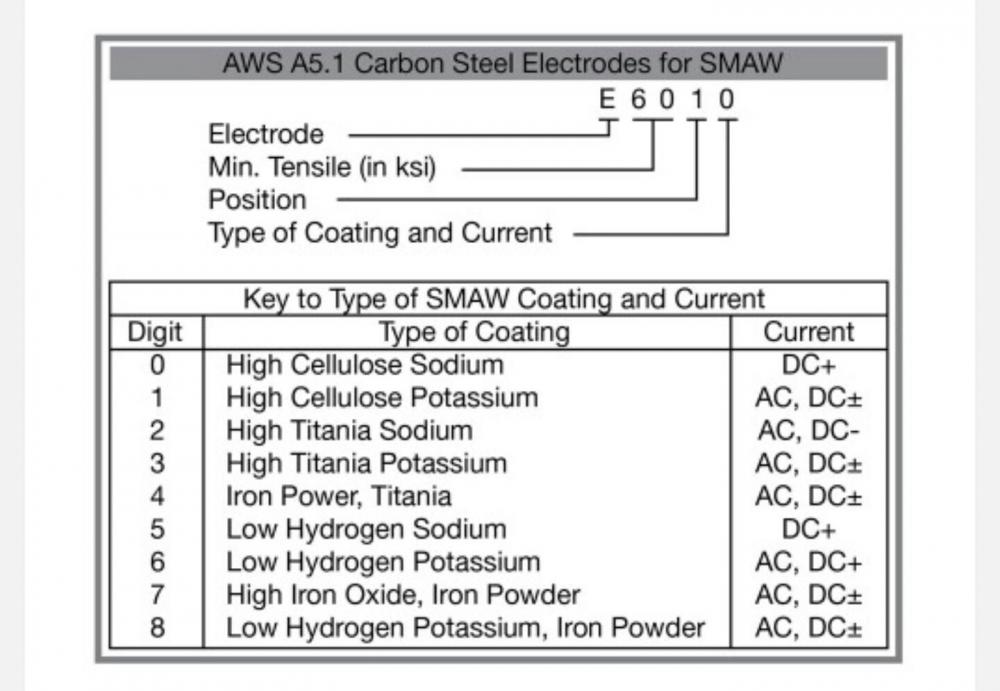

Here is a list that explains what the numbers on the rods means. As a pipe welder, I use DC power supply with a E6010 root weld, followed up with E7018 hot pass and cover pass. So in the 7018 rod, for example, 70=70,000 lb/sq inch tensile strength, 1=good for all welding positions, 18= a Low Hydrogen Iron Powder Flux coating. This rod is good for AC or DC current. The key for Low Hydrogen rods is to keep the flux very dry (water contains hydrogen) preferably in a rod oven. 7018 lays a very nice weld, easy to control. If you type "AC vs DC Welding Productivity" into your search engine, it should bring up the article where I got this chart, a very informative read, and nice refresher for me, since I haven't used AC in about 15 years. Also a weld supply store should be helpful in directing you which rods to choose.

-

That's a nice little welder, Das. I was going to make some recommendations about its use, and figured I better fact check, since I've been out of welding school a good number of years. Glad I did. Better to keep my mouth shut and let you all THINK I'm an idiot, than to open my mouth and prove you right!

-

Start of failed bottle opener

Glenn II replied to Forgingforfun's topic in Blacksmithing, General Discussion

Or a long walk back to get another beverage...if tending a long-term BBQ delicacy. -

Biggundoctor- I see your point. Other things to consider is marketability. If there is low demand for used CNC plasma torches prices will be lower. Versus, you can buy a new one with install, setup, warranty, and 1 year tech support. So do I buy a possibly wornout machine, spend $X to move it, try to figure it out on my own, pay a programmer to teach me to use it, and hope all goes well, or pay a few thousand more for new. Also, look at your press brake example. If the second owner had brought his to market first, would it have brought a higher price? When the first one sold, there were at least 2 interested bidders. When it sold, one of those bidders was essentially eliminated, leaving less competition. Also as the owner of the second press brake, should I choose a private treaty sale, how long would I have to sit on my machine with my price at $26,000, a price established by the auction method mind you, before I realized my price. If I don't get my money, another option would be to scrap it, which would result in much less than $13,000. Is the auction method perfect? No, but if used appropriately, it will generate the highest possible sale price for a given item on a given day. Not tomorrow's price or yesterday's. And yes, usually time is not on the side of sellers. With a collection of Blacksmithing tools, a properly marketed, competitive bid process would generate better prices than private sale, IMO. No disrespect intended or offense taken.

-

What did you do in the shop today?

Glenn II replied to Mark Ling's topic in Blacksmithing, General Discussion

Jennifer, I believe those crosses are actually made from one spike, cut in a Frederick's cross pattern and opened up. I have this one queued up in the shop for the next time I light a fire. -

What did you do in the shop today?

Glenn II replied to Mark Ling's topic in Blacksmithing, General Discussion

Elegant is hardly the word which I would use to describe it, but I thank you Ausfire and humbly accept your compliment. Also I screenshot your pic of RR spike builds. I can do/make plenty of things, but lack the much of the creativity during the design phase of a project. I'm not really the "idea man" on a project. Sometimes I start with a planned project in mind, other times I light the forge, heat some metal, and wait to see what developes. Sometimes I tell the metal what to do, and sometimes I listen as it tells me what it wants to do. Sometimes I tell the metal where to go, other times I follow as it leads me. -

What did you do in the shop today?

Glenn II replied to Mark Ling's topic in Blacksmithing, General Discussion

Ausfire, no power hammer here. All hand drawn. It's nearly down to 1/4" in the shaft, left a little more meat on the handle area. Overall length is about 14". I usually carry a tape measure on my pocket, so I stretched it out a bit and reached over my back. 14" seemed to hit all the hard to reach areas. I have a few friends who work for the RR, so I was looking for trading stock to get a few more spikes. Here's a better pic of the Business End of it... -

What did you do in the shop today?

Glenn II replied to Mark Ling's topic in Blacksmithing, General Discussion

-

Show me your Bottle Openers!

Glenn II replied to Arbalist's topic in Blacksmithing, General Discussion

I held the hot steel on the diagonal across the anvil and hammered the end "flat" to start the round part of the opener. Then punched and drifted the hole. Finished the hole on the horn, pushing the corners of the steel back into the round.