-

Posts

293 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Jon Kerr

-

Of course. I'm not interested in fashion- only finding the best solution balancing performance, safety and my neighbours. I'm simply checking if theres an alternative as the one in the picture above looks very different and worked well according to the other thread. In the UK (no idea about elsewhere) we can build to a certain extent under "permitted development". No permits needed, as such. My building, so far, falls under this. I'm only having trouble finding out what the rules are for flues on outbuildings, locally. Indeed, although this forum is full of people generously sharing their hard-earned knowledge and experience for free. I'm only asking.

-

Latticino- thanks for your reply! My local building codes for a flue assume you are using a high temp log burner or similar. As such, they insist on a twin skinned (and expensive) flue. Going by advice on this forum, thats completely unnecessary for a forge but I dont think theres any getting around it. I either build to code (twin skinned with specified distance to combustibles) or ignore the code and accept the insurance company might throw the book at me in the event of a fire. As it stands, I have 8" flue available to me already so if I can make that work somehow (rather than switching to single wall 12") then all the better in terms of satisfying local building codes. When I say "Get away with" I'm more concerned about local PLANNING permission rather than building regulation. Its very unclear to me according to info online what the laws are regarding installing a flue to an outbuilding, and the allowable height of such a flue. I've asked the local planning office who refuse to help unless to pay for, and submit, a planning application. Very unhelpful. My worry here is that I put a hole in my roof for a flue, buy all the appropriate (expensive) weatherproofing, a neighbour complains to the council and I have to pull it all down. If I install a 12" flue to the recommended height I'm not sure my neighbours, or the council, will be happy. That may be the way I HAVE to go, and just cross my fingers that nobody complains, but I'd like to explore other options. I've looked at Uri Hofi's side draw hoods and they look great, but they do still have very tall chimneys to get the pressure differential and encourage draw. His photos on the blueprint are for a very tall building! Mine is only 2.5m to the top of the pitched roof. I'll be using a coke forge so smoke should be less that charcoal/coal, right? Anyone else got any thoughts/experience with a forced air flue system like Gote's?

-

Hi everyone, Firstly, apologies as usual for my newbie questions. I'm not trying to cut corners here, and I've done my research, but I'm not sure that the "recommended" solution is going to work for me for the reasons given below.... I'm in the process of building a new shop, and am now agonising over my flue.... My issues are as follows: Height of the chimney. I want to keep this to a bare minimum which is obviously contrary to the "ideal", which is as high as possible! Im concerned about local planning permission and dont want to bother the neighbours. Cost. I need to keep costs down (doesn't everyone?). I already have a couple of metres of twin wall 8" flue so it would be great to make use of that if possible. Running flue through the roof worries me given the rainy british climate, and all the associated flashing, storm collars, etc are EXPENSIVE. Having done my research on the "super sucker" hood, and taken advice of those on this forum, thats pointing towards a 12" single wall flue running straight through the roof and standing 4feet proud of the highest point of my building. I just don't think I'm going to get away with such a monstrous flue which planning permission or my neighbours..... (For info- my shop is 3.5m x 5m, log cabin construction, with two windows and a double door which will be opened when forging.) I did some more digging and found these images of gote's chimney. Unfortunately it looks like he's been inactive on this forum since 2017. Can anyone give me any advice on this type of forced are flue? Will this work with a side draft hood? Will 8" be acceptable in a forced are system? Any guidance on the type of shop vac/blower needed? Could I achieve the same with a shorter length of flue? Can this style of flue terminate below roof level thanks to the forced air? Any pros/cons of this style of flue? Any design guidelines? I'm wondering whether I can do the same as Gote. i would keep a similar height of the initial pipe, but the horizontal outlet would only be 1m to the wall. Would this still work? If it works, this would be perfect as it won't bother the neighbours, and I can use the 2x 1m lengths and 2x 45degree connectors of 8" flue that I already own.

-

Is single wall ok even where it passes through the wall or roof? By building regulations in the UK it would seem you'd need twin wall but maybe in practice its not worth worrying about? How hot/cold are we talking?

-

What kind of flue would you gus be using? Ive been assuming twin wall flue like you use for boilers or log burners but its insanely expensive. I managed to get some 8" stuff cheap which helped but if I need to switch to 12" its going to cost me £500+ !!!! Am I missing something? Is there a cheaper alternative?

-

Thanks Frosty! Yeh the sound-dampening and thermal properties were major reason for going this way. Im really pleased with the building. I'll be adding a side draft hood into an 8inch flue going out the back wall and up. (Coke forge)

-

I just have to limit my forging to reasonsble hours of the day. .... this is England, unfortunately we all live in top of each other as land is in such short supply.

-

Well I've been busy lately. I laid my concrete slab a couple of weeks ago, and the timber for my shop turned up on Thursday morning at 7.30am. By 6pm the same day it was fully built! By lunchtime the next day the roof was insulated and tiled (felt shingles). Now I just need to buy my new forge from The Iron Dwarf as my JABOD was a casualty and went in the skip during the tidy up. (Deliberately.... it had served its purpose and needed an upgrade). I couldnt be happier.... I've been dreaming of having a workshop like this for years. Now I just cant wait to get back to Forging! I also started work on my new hardy plate "anvil", to complement by steel block anvil.

-

-

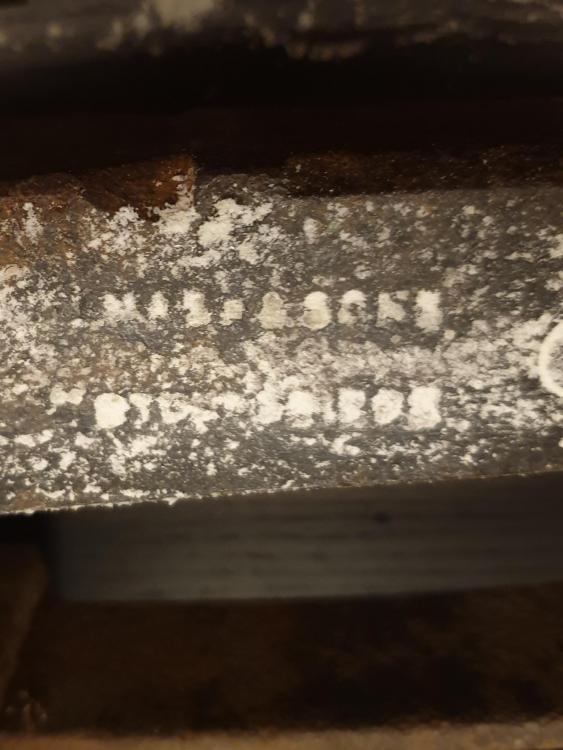

Thanks Thomas. I just weighed it- its 20kg. Is it possible thats what the stamped "20" refers to? Does this also date the vice approximately given the introduction of the metric system? I tried the flour dusting but still cant make sense of it. Hopefully someone has a better eye than me! *EDIT* the text was upside down to the "20"! Threw me completely. I can now read "Mas* & Sons" "Stone****s".... any ideas? Google failing.

-

Jaws are 4inches. Not sure on weight unless I stick it on the scales- what does that tell me? it has a number that looks like 20 stamped on the side, and text I cant identify. I'm almost sure one word says "GHOST". Any ideas anyone?

-

Forgot to say, thanks everyone for the advice regarding the forge and the car springs..!

-

I found a leg vice!!!!! We were wandering around the car boot sale on Saturday, and my wife pointed to something on the floor and said "Isn't that what you wanted?"..... and there it was. Its got some surface rust (or maybe just a good patina ) but the screw is well greased and looks completely free of damage. Jaws are pretty tidy, leg is slightly bent. The mounting plate etc is all perfect. The only damage is to the handle which is a bit mangled but useable, and easily replaceable should I ever feel the need. I managed to get the price to £40 which I think is a good price (as compared to eBay auction prices). Pictures to follow.

-

Bronze axe with wolf head poll

Jon Kerr replied to Rashelle's topic in Axes, Hatchets, Hawks, Choppers, etc

http://www.hallowellco.com/nrba_fall_conference 2015 Machler.htm Thanks Rashelle! I just found this link, looks like a good method? -

I've picked up 3 old broken car coil springs during my trip to the car garage today. The only ones the guy gave me were a) painted black, and b) thin car variety, say 10-12mm diameter. Obviously I'm not complaining but next time I might ask if there are any bulkier van/4x4 ones with no paint. So- I've already read some posts on here regarding spring coatings, and I'm thinking I might go along the lines of very irresonsibly chucking them in a bonfire and burning the paint off from a safe distance. Poor planet... 1. What kinds of projects are these 10mm round spings useful for? They seem a little thin for punches and other tools. Is upsetting advisable to get to a more chunky diameter? Or more effor than its worth? Also, while I'm asking daft questions..... 2. Anyone got any tips for what a "Posh Jabod" (or similar side blast forge) might look like? There are a few side blast forges on eBay etc but very expensive, and I'd like something long enough that I can sit a side-drawing hood down into it. 3. Any design rules/guidelines for a sheet metal side blast that differ from a JABOD? 4. What do people usually line the bottom of the forge with? Dirt/clay like a jabod? Firebricks? or fancier refractory cement?

-

Bronze axe with wolf head poll

Jon Kerr replied to Rashelle's topic in Axes, Hatchets, Hawks, Choppers, etc

This is absolutely stunning. Is there any guides/videos out there for how to forge the wolf head? I'd love to try this. -

What did you do in the shop today?

Jon Kerr replied to Mark Ling's topic in Blacksmithing, General Discussion

Nice work Mudman! Look great and nice and neat as far as I can see. I feel your pain- I learnt to do this from 16mm square bar last week and it certainly is a workout! ..... now you have to do the second of the pair! -

Last week I finally made it along to the Much Hadham Forge for my first proper bit of blacksmithing training. I had a fantastic day with the resident blacksmith, Richard Maynard, and learnt a huge amount. My main objective for the day was to learn how to make tongs, including all the necessary basic techniques..... drawing out, punching, etc. The picture attached shows what I achieved during the day. I made 3 types of tongs- a "quick and dirty" simple twist and drill set, a set of bolt-jaw tongs from a set of tong blanks, and a set of normal tongs wtih 16mm square bar. I actually had time to make another set of normal tongs also which weren't pictures. The bolt jaw tongs are finished (might tweak the angle of the reins) but the rest still need some work- the rivets aren't all done so I can go back and round the handles nicely and finish them off. Great day and now I can't wait to get back to forging at home.

-

Great advice thanks Frosty + Thomas. Feel much more reassured. I cannot WAIT to build this shop.

-

Welcome! Best of luck getting started.

-

Sorted, cheers.

-

Hi all, I'm looking for some advice and a bit of a sanity check regarding a workshop design. I'm fortunate enough to have space at the bottom of my garden for a 5x3m workshop. Originally my intention was to build a concrete block workshop on a concrete foundation. I was planning to build a forge inside, with a side-draw flue. Once I started to do my research regarding ventilation, and on reading other posts on this forum, I've been scared off of this due to the threat of carbon monoxide poisoning. I'm currently forging completely outdoors so its not been an issue so far. Do most people forge in a kind of "open" sided shop/lean-to? Surely the "blacksmith-shops-of-old were indoors? I'm a bit baffled by this. Furthermore, the cost of the concrete base is proving to be prohibitive. As such, I'm looking towards some of the really nice log cabins you can buy and planning to place it on a lighter concrete raft (after taking advice from many sources). As such, my latest plan is to build a timber log-cabin workshop with my forge under a lean-to on the side of the building, with a flue running through the lean-to roof to allow for a side-draft hood. Unfortunately thats less than idea in terms of exposure to the wind and rain, and noise for my poor neighbours.... I'd prefer to forge indoors if I can understand what level of ventilation might be acceptable? Obviously both methods will need appropriate fireproofing around the forge and anvil with cementboard etc, fire extinghuisher and running water on hand...... So, in summary, my two questions are: - Can I safely forge indoors with a side draft hood and double doors open? - Any tips for forging in/near a timber workshop safely?

-

Thanks everyone.

-

I'd like the black scale look. Will this be achieved on stainless? Also, unfortunately stainless seems to be harder to get hold of locally than mild....

-

Hi all, I'm about to forge some accessories for my new bathroom (towel ring, toilet roll holder, etc). Is Boiled Linseed Oil the best stuff to use to protect it? I'm obviously concerned about rust in the bathroom environment! (might turn out to be a terrible idea long term..)

.thumb.jpg.66687c69f6af7c2673bdbdf90c30c1d1.jpg)

.thumb.jpg.d90793d69ed1d0c77ad7b26248323726.jpg)

.thumb.jpg.c9d9d4ff3cc5ff91d8b2e988b6f5ac95.jpg)