Trevor84

Members-

Posts

168 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Trevor84

-

Oh don't you worry, I promise that I will come running with some confusion soon enough... I started school last September, college classes after 20 years out of school. I hadn't even completed grade 10! Through disability I was blessed to have financial support, (even if I did have to debase myself and fight tooth and nail). I am taking the human service worker certificate, its a one year course but that's BS! Every instructor says that it should be a two year due to the course requirements. Blah blah blah! The first semester was rough but got me two B's and a C. I just finished two heavy classes (counselling strategies and case managment) A- and a B+! I struggled, from chronic pain from degeneration and constant muscle spasms and then the massive emotional journeys through my life. LoL, Yuup, human service worker, blacksmith, rocket tryentist. I hope you are doing well aaaaand I am working my way through redesigning my little shop. I am almost finished my 2x72 grinder and then I will be servicing the old ir ovens! You happened to catch me at the perfect time... I just walked into the shop full of excitement and aspirations for some productivity. Now I feel obligated to to hurry up and get caught up now that I blabbed about new tools and shop designs. Ear plugs are going in, smock is going on and my goals are specific! Sincerely, Trevor (Lone Tree Forge) Ps, if I don't reply for the day it is because I have become hyper focused and on task.

-

Tungsten carbide files, that makes more sense than the diamond ones.

-

https://youtube.com/watch?v=UIRp5VJrQqM&si=EnSIkaIECMiOmarE The left side reacts the same whether the brick is in place https://youtube.com/shorts/wcusMZY5Gz0?si=EnSIkaIECMiOmarE Sorry I moove so much. Using a needle valve on each burner makes a lot of sense, good point ☺

-

Hey Mike the left burner wants to blow like crazy, the burner I have to choke like foghorn and the weasle. The burner on the right seems to react like normal in a cold or hot forge while adjusting choke and as the forge heats up you can open the choke and the flame reacts normal looking. The left burner wants to blow the flame right off and all over the wall across from the burner ignites like a magician chucking a blue fire ball. No slow sloppy blue flame but as if the burner want to blow through the wall. I'm trying to upload a video I to YouTube to share the link.

-

What's your latest blade look like? Post em and let us see.

Trevor84 replied to HondoWalker's topic in Knife Making

My latest, chainsaws bar stock removal with a hand carved maple (maybe) handle. Wrought iron bolster and pommel. -

Wow I gotta lot of catching up to do but I wanted to shine this magic mistake and improvement. I shared these 3/8" 0.4mm mini burners before but couldn't get them to overcthe pressure in the forge and ran rich. I trimmed a half inch off the back so I could get the orifice a bit deeper, then I tried clamping the tube in the vise horizontally and proceeded to cut the threads deeper buuuuuuut the side I was tapping ie backside of skiny supports and the threads locked and I twisted the intake. Oh the tragedy, the failer the oh, wait it twisted straight..... Seriously the overall profile of the 3/8" tube stayed straight as an arrow but with a twist. These tiny burners are hard to take pictures of but these two changes were repeated on the second burner first try (crazy maniacal laughter) These run hard, loud and hot! It looks like I have Flares on the end but they are only spacers there is no over hang the flares are shaped into the refractory. I have to stop plumbing my burner's together this close, I always end up with one side running a lot harder. Does my plumbing at the burners look like it could cause a kind of cavitation (?) as the gas splits at the last T? When I plumb like this there is always one burner that goes whomp, whomp, whomp so the one burner has to be choked right out until the internal temp is up. Or it's just what happens when you try to duplicate something, which is why we use the chokes eh... Yes I'm Canadian EH. "swirl" ummmmmm I wish I could see the effect my twisted intake had but these are so small it's hard to photo. I mean I wonder if and how much the twist changes things, I guess if I went from rich to vavoom I must be on to something. Mikey I really like the baffle concept to adjust secondary air.....

-

What did you do in the shop today?

Trevor84 replied to Mark Ling's topic in Blacksmithing, General Discussion

I've used straight beeswax on metal like bbq tools or other items that you're able to just rub against the block wax in the past. The first 2/3rds of the Johnson's can was used by dipping stuff like forged snails, leaves, key chains etc (I wasted lots I'm sure) On my hammer handles and other wood in the past had been wiped down with BLO and terpentine. I leave my hammer handles with a rasp finish, fibers burned off and oiled while hot until oil refuses to absorb. I was surprised how fewer blisters I got and the increased hammer control. I'm out of beezwax, BLO and terpentine so now is a perfect time to invest in a few new products. Carnuba wax definitely sounds like a common denominator here. Frosty, ya using what's at hand was the goal this time and the Johnsons was scraped up out of the drip pan and stuffed into the can, it had a mix of beez wax in it already so I figure wth soften it up a bit more and use a stiff natural brush instead of a rag. My hands are clumsy now so I fumble cold things.... I don't like fumbling hot stuff ;-) -

What did you do in the shop today?

Trevor84 replied to Mark Ling's topic in Blacksmithing, General Discussion

Go figure the raw linseed and terpentine mix that I put on before posting here still leaves an oil sheen on your finger when handling the wood. I'll have to pick up some new supplies next time I'm in town thanks guys for the tips so far . I found an old tin of Johnson's paste wax and thined it a bit with terpentine and a blob of that raw linseed..... So far it seems to have left a decent medium dark finish on the metal bits when applied at a light sizzle with a brush..... Time will tell, I'll shoot a pic later if I get some mounted. Good Thanks, I am reffering to raw linseed not boiled, I believe raw linseed is basically flax oil. Maybe i have to get the flax oil from the health food store.... I do know that flax oil is used on cast iron because of the polymerising and can withstand something like 400*f once its fully polymerised. As for the finishes on my materials I should have been reading more along the way I just got carried away puttering ..... Please don't think I asked a question then ignored yawlls advice. -

What did you do in the shop today?

Trevor84 replied to Mark Ling's topic in Blacksmithing, General Discussion

No of course we don't eat our Coates geez you're silly. I bought the the raw linseed for a couple cast iron pans I want to season so I had it there and like the colour when dabbled a piece of this wood, that's the only reason for food grade coat hooks (not goat hooks) Orange oil, I don't mind spending a buck but isn't that stuff like gold necter? Carnuba wax eh, I'll have to look for it next time I'm at the store, thanks Do you make this feed and wax or us it a premixed -

What did you do in the shop today?

Trevor84 replied to Mark Ling's topic in Blacksmithing, General Discussion

Oh good morning out there, I haven't done nuthin yet today but I have a quick question to start the day. I'm about to get these finished off today, wink wink, I have oiled these boards with raw linseed oil/terpentine mix. For the steel coat hooks, should those be clear coat or should I just mix up linseed beeswax terpentine mix for them. If they are indoor use. (Blo polymerises quicker right? But raw linseed is food safe I think?) Bare steel, Linseed/beeswax/terpentine, Clear coat, -

What did you do in the shop today?

Trevor84 replied to Mark Ling's topic in Blacksmithing, General Discussion

Well I just need to seal the wood and clear coat the hooks. These boards are 18" long so I will pre drill and counter sync holes to match 16" centers. This is old dimension one by four so their a solid 1" thick rough cut fir (maybe) and weathered so I ran it through the big planer quick and light but left the edges rough, the roof screws holding the hooks are just shy of punching through the back side of the boards so should hold pretty darn snug. -

Blacksmithing gems and pearls

Trevor84 replied to Glenn's topic in Blacksmithing, General Discussion

I read this back at the beginning of this thread and I can't agree more I to "don't waste a good bend over". Pick as much up as you can while you're down there because you only got so many "stand up's" in a day eh. -

I will be adding on to the bench/shelf once I formulate a full plan. When I talk about wrists and arms youll have to stretch your imagination and pretend there are bricks tucked under his elbows. I'm struggling to fully visualize it myself but I'm thinking something that adds to the "minion" look. CI.... The floor is about 4"x12" and about 7"-8" so let's say roughly 400CI.

-

Ok that makes sense thank you....

-

Oh it's "sunlight" dish soap with enough water that it'll spray. Like I say I've got a small shop so it's easy to have it sitting there and since I'm always swapping around burners and forges I just spritz them before I spark up. This must be a real stupid question but can you smell the oxy? Can an oxy leak ignite like propane or acetylene or does it disperse fast enough? I don't use those kinds of torches so I really am curious.

-

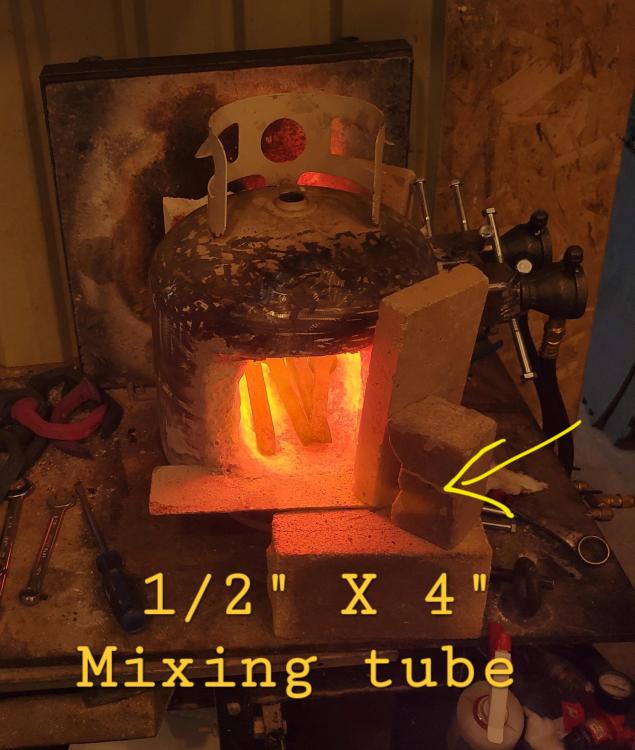

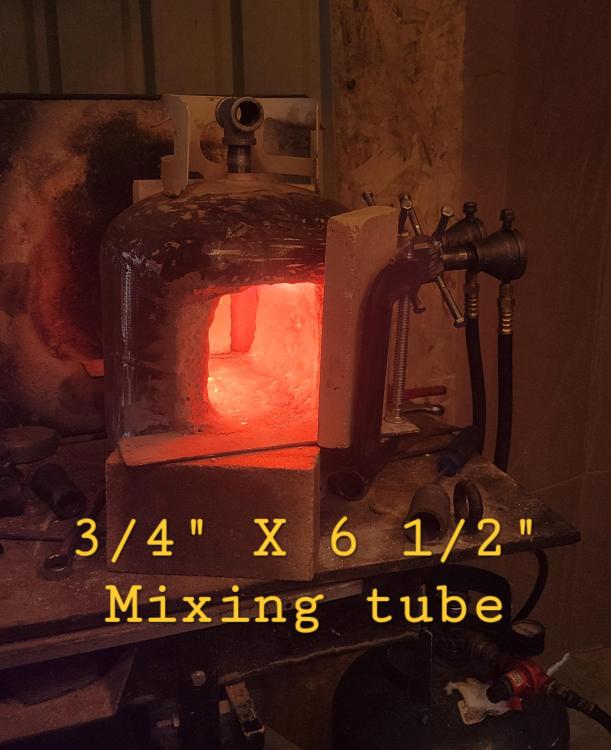

Honestly Mikey the second image is within 10 min of ignition.... This forge has 2" insulation and the floor and ceiling have closer to 3". The hot face is "unicast 2800" a dense castable refractory, 3/8" thick on walls and ceiling 1/2" and then it's finished of with ITC 100 ht. I would throw 3 spikes in and by the time I got to bending the third it was close to the blister point. I have to fashion some kind of system to secure brick/baffle doors that resemble hands or arms. I'm thinking along the lines of a "minion" holding binoculars with hands on the burner mounts with some kind of articulation for the wrist and the arm acts as a brace for the bricks or kiln shelf. The above image is from the other day with the half inch mixing tubes and here I did not adjust the light filter so the forge looks like a reactor core instead of high orange.

-

-

What did you do in the shop today?

Trevor84 replied to Mark Ling's topic in Blacksmithing, General Discussion

Well that was the point I was making ;-) (trying) having random stages of projects in the forge at the same time gets messy and confusing. -

These burners are the 0.8mm not the proper 0.023. It's hard to see but there is too much dragon breathe, the forge is hot but there's a wall of fire outside of the door. Here is the same burner head but with a 3/4" mixing tube and no reducer. Almost no dragon breath, and the heat... Oh my wow!

-

I know more about you guys than I do Ron but by the way he wrote those blue pages he seems like a decent feller so I hope his detachment has helped rather hinder his health. I have read his page over and over, I am not able to quote or cite pages or specific paragraphs, I struggle to recall specific details but the information is definitely upstairs somewhere. Time, age, knowledge, wisdom, mistake ughh I'm a pup and I'm feeling those crowed the shadows. I may never sit on your picnic table Jerry but the information you and Mike and people like Ron have definitely left something for a lot of random strangers..... People that believe "Frosty" T sounds cool and don't realize that Frosty is a person.

-

What did you do in the shop today?

Trevor84 replied to Mark Ling's topic in Blacksmithing, General Discussion

I think it's safe to say that we should all have that in our list. I am small scale and don't really sell I mostly just give away but I like making things in sets so I can keep things straight in my head. Things that normies don't think about like which tong at what step and reach in from what angle and all the way down to how you place the awkward piece back in the forge. (you can't do scrolls and hooks or they hang up on each other sort of thing) Those are fractions of thoughts but still when you're in the heat of the moment it's nice to have that production line way of thought. -

What did you do in the shop today?

Trevor84 replied to Mark Ling's topic in Blacksmithing, General Discussion

Jobtiel, wonderful m8! I like the straight line along the top and that's a good Idea to match a store bought for the times you don't want to make a pile of shavings. I made these top tools quite awhile ago but just leand up the struck ends. I sure do like them.... no burnt wrists from holding a straight punch or chisel or whatnot, when I was at the anvil all the time that radiant heat didn't seem so dang hot so now f that just give me a handle instead. -

What did you do in the shop today?

Trevor84 replied to Mark Ling's topic in Blacksmithing, General Discussion

Yes I agree M. J. L. There is definitely a market for rentals on those archway..... $50 bucks 50 bucks 50 bucks as wedding season starts. -

What did you do in the shop today?

Trevor84 replied to Mark Ling's topic in Blacksmithing, General Discussion

Gotta love those days right Thanks for the observations, I'm heading to the shop in a few so I'll give a couple of these a few tweaks and then try out a few new ones Dang JHCC that's wonderful! -

What did you do in the shop today?

Trevor84 replied to Mark Ling's topic in Blacksmithing, General Discussion

Hello again, a couple days late for the "today" aspect sorry I hope it's ok. I've made all sorts of hooks and whatnot but with my neck and back I am drastically limited on what I can do and how long. Trying to draw out tapers and rolling tiny scrolls is too exhausting, mentally and physically so I've been thinking of simple little projects I can do. So far these hooks were two heats, 1: bend in the vise 2: use set hammer to flatten/true up the flats where the screws will go and mount to the wall I'm not sure if I like the angles I've gone with, I'm thinking I may have to do more of a 90* at the bottom but if I was to hot rasp the sharp corners at the end of the first heat these would be quick and dirty.