-

Posts

370 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by FlatLiner

-

I believe they are manufactured by branco in Czechoslovakia. A few guys on YouTube have used them and/or are still using them. I think black bear forge has one he has used in the past, he now uses a Fontanini anvil, and I think old hickory forge currently uses one. My thoughts are if the price of a new anvil is close too or the same as a used one then go with the new. Modern metallurgy is better by far than anything they did 100+ years ago.

-

How many pounds and how wide is your anvil?

FlatLiner replied to Fly's topic in Anvils, Swage Blocks, and Mandrels

That is a huge Columbian ForgedinFire123. Show us some pics :-) -

I could be wrong but as far as I understand it, the stepdown between the face and the table is indicative of the thickness of the hardened steel face on wrought Iron and cast iron anvils.

-

removing paint from an Anvil.

FlatLiner replied to Sean Duffy's topic in Repairing and Modification to Anvils

A wire wheel on a 4" grinder will do it. Don't use the knotted wire wheel, it will take metal off with the paint. -

How many pounds and how wide is your anvil?

FlatLiner replied to Fly's topic in Anvils, Swage Blocks, and Mandrels

Sisco 125 lbs 4.5" face Columbian 135 lb 4" face Post anvil 120 lbs 5" face Post anvil 265 lbs + 4" x 8" face Cube anvil 65 lbs 5" face -

History of American Indians and Forging

FlatLiner replied to Alan DuBoff's topic in Historical Ironwork

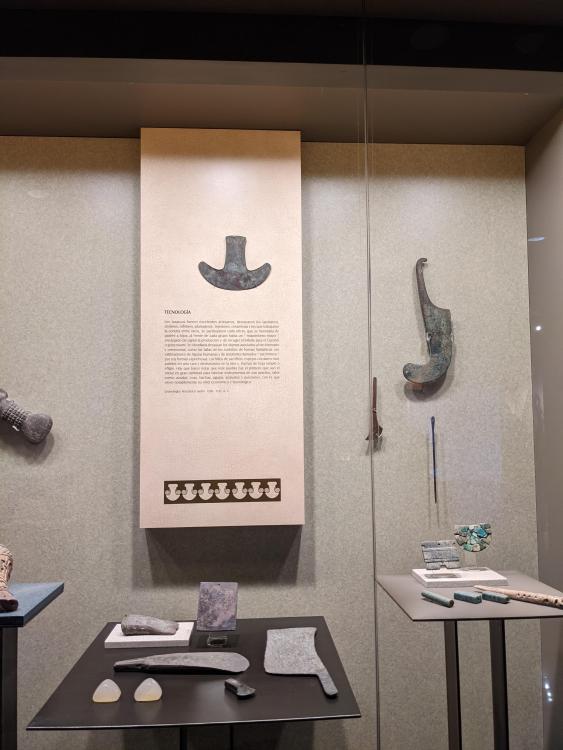

They didn't have much in descriptions, age, or composition etc. I was looking for it. Most of the display had been taken down. They are remodeling. I remember seeing a lot more axes of varying shapes and sizes. When I get home I will have to go through my old pics to see if I have some of the old display. -

History of American Indians and Forging

FlatLiner replied to Alan DuBoff's topic in Historical Ironwork

I didn't see any iron. -

History of American Indians and Forging

FlatLiner replied to Alan DuBoff's topic in Historical Ironwork

I was just in the Museo de Antropologia de Mexico. Here are some pics of bronze, gold, and metal works from around Mexico that they cut have on display. -

First anvil feedback request

FlatLiner replied to TheDane's topic in Anvils, Swage Blocks, and Mandrels

I recall that some wrought Iron anvil makers had a handling hole in that spot under the faceplate. Does it still have the hardened face plate? -

Those edges don't look to rounded to me. In the book Practical Blacksmith by M.T. Richardson on pg. 92 a blacksmith from about the turn of the century wrote. "For my own part, I am satisfied not only that the sharp edges are useless, but that they are also destructive of good work. I cannot account for their existence except as a relic of a time when the principles of forging were but little under stood. I want both edges of my anvil rounded, not simply for a part of their length, but for their whole length. To my mind the ideal anvil of 130 pounds is one having its edges (from the table to about 2/3 the length) rounded to a curve of three-eighths of an inch radius (from about 2/3 to the heal) rounded to a curve of three-sixteenths or one-quarter of an inch radius. The (edge of the heal) can be sharp to satisfy the unconverted.-By X."

-

Power Hammer that I did.

FlatLiner replied to MerlincMan's topic in Power Hammers, Treadle Hammers, Olivers

That's an awesome little power hammer build. -

History of American Indians and Forging

FlatLiner replied to Alan DuBoff's topic in Historical Ironwork

My wife is from Mexico City, I like history and museums. I have been to Mexicos National Museum of Anthropology a bunch of times. It's amazing. -

History of American Indians and Forging

FlatLiner replied to Alan DuBoff's topic in Historical Ironwork

Apparently there were/are tin deposits in Guerrero, Mexico close to some copper deposits there. They had some knowledge of making copper alloys Cortez stated that in the markets if Tenochtitlan "hatchets were sold made of copper alloyed with tin" there are other Spanish accounts of them alloying copper with gold. One ancient Mexican copper chisel was analysed and it came back as 97.87% copper and 2.13% tin not enough to be what we call bronze. A different Aztec chisel was analysed and it came back as 91.40% copper, 3.07% tin, .82% lead, .53% iron, .08% cobalt, and .82% sulphur. They have excavated a site in western Mexico where all points and arrowheads are 90% copper and 10% tin. There are Spanish accounts about how the natives knew how to use blow pipes to smelt gold, silver, and copper. It's all pretty interesting stuff. -

History of American Indians and Forging

FlatLiner replied to Alan DuBoff's topic in Historical Ironwork

No idea, I don't even know if they are truly bronze, but supposedly the copper deposits are some form of naturally occuring copper alloy. -

History of American Indians and Forging

FlatLiner replied to Alan DuBoff's topic in Historical Ironwork

In the Museo National de Antropologia de Mexico they have a whole room full of copper, brass, bronze alloy axes called Tlaximaltepoztli that have been found down there. Most people skip the room or just breeze on through without so much as a thought of when, where, or how they came to be. There were copper mines being mined in the area of Michoacan pre Spanish era. The Aztecs, Maya, Purepecha and Mixtec's all knew how to work copper, bronze, gold, silver etc before the Spanish arrived. -

I have a little 45lb cast steel trunkated anvil that I suspect is a Columbian. The maker marks are missing, I believe they were taken off and it was sold as a lower tier anvil because of casting flaws but the dimensions and shape add up to Columbian. I have forge on it with a striker using a 16 lb sledge just to see how it held up. I can say that the little anvil held its own. It's a great little travel anvil.

-

That's about as good of rebound as I have on my forklift time anvil but rebound isn't everything. My forklift time anvil moves hot steel as easily as my "real" anvils.

-

Meet James Hay, of Hay-Budden

FlatLiner replied to Black Frog's topic in Anvils, Swage Blocks, and Mandrels

The chief of the clan didn't always follow primogenitory (father to son) it was succeeded according to the Celtic system of tanistry which dictated that the heir-apparent to the chief was elected during the chief's lifetime and it could be a son, nephew, brother, Uncle, etc. tanistry, a custom among various Celtic tribes—notably in Scotland and Ireland—by which the king or chief of the clan was elected by family heads in full assembly. He held office for life and was required by custom to be of full age, in possession of all his faculties, and without any remarkable blemish of mind or body. At the same time and subject to the same conditions, a tanist, or next heir to the chieftaincy, was elected, who, if the king died or became disqualified, at once became king. Sometimes the king’s son became tanist, but not because the system of primogeniture was in any way recognized. Indeed, the only principle adopted was that the dignity of chieftainship should descend to the eldest and most worthy of the same blood, who well could be a brother, nephew, or cousin. This system of succession left the headship open to the ambitious and was a frequent source of strife both within families and between clans. Tanistry in Scotland was formally abolished in the early 17th century during the reign of James VI of Scotland (James I of England) and the English system of primogeniture was substituted. https://www.britannica.com/topic/tanistry -

Fixing a chipped anvil.

FlatLiner replied to QbBlacksmith's topic in Repairing and Modification to Anvils

Richard Postman I believe said that the last 4-5 years Columbian anvils we're cast in Sweden. -

Fixing a chipped anvil.

FlatLiner replied to QbBlacksmith's topic in Repairing and Modification to Anvils

That's funny, I also have a 135 lb Columbian that I picked up because it's edges were slightly better lol. -

Fixing a chipped anvil.

FlatLiner replied to QbBlacksmith's topic in Repairing and Modification to Anvils

It looks like the typical ranch anvil that was used for cold forging horse shoes. I picked one up in Evanston, WY that had worse edge damage and I just flap wheeled the edges to keep the chips from spreading and made an anvil block for when I need a "sharper" edge. -

The local want adds where I live have 4 people looking to buy anvils, there is a trunkated fisher and two Vulcan anvils that have been for sale for months in the same want adds. When a Columbian, Swedish, Trenton, Hay Budding, or any English anvils goes up for sale they are usually gone in less than a day. Maybe that gives you an idea of how different anvil manufacturers are valued in my neck of the woods.

-

TFS Anvil vs. McLellan Anvil

FlatLiner replied to Lior's topic in Anvils, Swage Blocks, and Mandrels

I enjoy lurking on this board. Occasionally I pipe up and post something. Do I really need another anvil? No I don't, I have plenty of anvils and improvised anvils. I just find it ironic that there are rules that seem to be set in stone for some but not for others. That the "mods" don't seem to tolerate certain types comments from some but allow the same type comments from others. I am not going to go into specifics because they are plentiful. I agree with what you said Twisted Willow, I have also seen that most of the time the people on other boards bad mouthing iforgeiron are in the wrong. That being said, no hard feelings, no harm no foul. Keep up the good work on this board. -

TFS Anvil vs. McLellan Anvil

FlatLiner replied to Lior's topic in Anvils, Swage Blocks, and Mandrels

Calm down, Apparently you have no sense of humor Glenn. What do you think the grinning Emoji means? No wonder this board gets trolled on in other boards. -

TFS Anvil vs. McLellan Anvil

FlatLiner replied to Lior's topic in Anvils, Swage Blocks, and Mandrels

That's my favorite pattern of anvil you make Foundry Guy. I would love to put it up against my other cast anvils to see how it performs. But I don't have the discretionary funds right now.