BartW

Members-

Posts

281 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Belgium near Hasselt

-

Interests

Forging (knives); diving (instructor)

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

First picture in this thread show the really nice sloping curve. The horn usually isn't symmetrical; but the rounding very gradually slopes towards the flat; so you have essentially a wide choice of edge-radii to choose from when forging. In practice; this means french anvils are less susceptible to farriers damaging the anvils drawing out the toes of horseshoes.

-

Having used both, I prefer the German style anvils. Sometimes it's handy to be able to rotate a hardy tool and still make it fit. In the French setup; they cannot be rotated. Most of my home-made hardy tools however fit so tight; and the hardy hole isn't perfectly square; they cannot be rotated anyways. But that's more my fault. If i'd take a couple more heats and made it fit while rotating ... Also the french style anvil has a really cool long curve on one side; which is very handy drawing out, even if the anvil is mounted too low or too high.

-

The markings are fairly simple and self-explanatory: Maker: "Joris et Dambrun" (company) location: "a Paris" (in or near Paris) Serial nr: "N 30772" Weight: "P 112 KG) (Poids 112 Kilograms) I wouldn't worry about the "crack" in the bottom. These were cast up-side-down, so it could be a "molten-steel"-fold and not really a crack. Once they cooled enough, the mold was broken open , maybe some refinements were made like the hardy hole ( so a bunch of burly dudes with 20 pounds sledges) .. then it was rolled outside and put under a water tap to harden, and after a specific amount of water the residual heat in the body tempered the anvil. They would return the day after, check the anvil, and start cleanup on big milling machines. Fascinating proces to observe (I've seen it once in Belgium) This method does result in fairly hard tips, this had advantages and disadvantages. The hardy hole is also specific sided; and you need to forge tooling for it, but first make a specific punch to push out stuck tools ( been there, got the T-shirt) .

-

BartW started following Should I get a training anvil for blacksmithing? , French Anvil Identification , freestanding blacksmithing frankenstein vise and 4 others

-

In France, in the city of Saint-Denis (Paris), there was a steel foundry called "Joris & Dambrun" ... like 50 years ago, they went bust during WO2. It helps if you can search in french (I speak french & dutch, I'm from Belgium). They were known for producing lathes; apparantly they also made anvils. As for quality & construction; in this part of the world the classic wrought iron body with a steel face were not very common; they were mostly cast steel anvils in the past 150 years. Most anvil producers held rather high quality standards and rejected about half of the castings. Access to high quality steel is also no issue in this part of the world. However, as Frosty said, the anvil made it across the pond, and it could have been in a fire. To be tested I suppose.

-

There is an open-air museum-ish village close to here; and they have quite a few hundreds of years old houses. Including a forge But in the exposition, there a lot of threshing flails, probably because they look good. But as for the wood used; the shaft is usually light and flexible; so elderberry, hazel. The head is usually heavy and hard; and they are all Oak. As for crabapple; I actually haven't used that before. I know Apple tree makes lousy handles; while pear wood looks nice on knifehandles, stabilized, but isn't strong enough for handles.

-

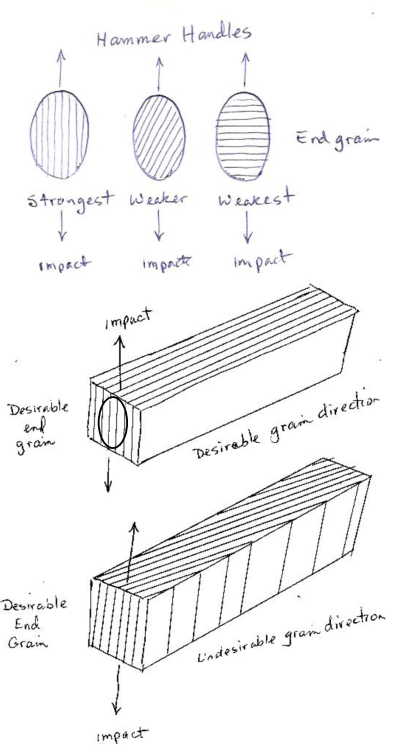

Europe has much variations in climate actually. Nordic birch (slow growing birch due to the cold) is the same tree as the birch growing in my backyard. Nordic birch is a good handle material and quite hard and resistant. The birch growing in my backyard are soft like pine. Hickory doesn't grow terribly well over here; but Robinia (Robinia pseudoacacia) Is the most dense and resistant natural growing wood in western europe. Ash, Beech, chesnut, hazel, elderberry, buxus, afzelia, rhododenderhon, rozewood, magnolia ... I used them all for handles. typically I avoid most pine and oak (they "bleed" some kind of acid turning your hands black) variations. If it's soft enough for me to dent with my nail; I leave it alone too. Keep in mind that "how" you cut the handle and mount it is really important in longevity of the tool. I attached a drawing I found on the internet a loooooong time ago.

-

Hello All; I've got some information request concerning the vise below. The story: Worn screwbox; and broken handle bar and foot. I couldn't get the handle bar to weld correctly, it's some funky very large grain iron which makes welds go brittle. Then I found a truck kingpin thing to mount a spare tire; it is partially threaded M20 , not drilled all the way through. I cut that thing in half; the threaded section forms the screw-box; the non threaded half is secured to a threaded rod, and I machined a washer in front. Then added 2 nuts with the thread cut out to form the handle-bar holder; and a threaded rod with the threads cut off is the handle. To protect the threads I welded a pipe over it, and added a key to prevent the box from rotating. Then I manufactured a V-spring from a leafspring (this is WAY overkill). It clamps really slow (but pinches hard). It isn't ideal; trapezoid thread would have been better and faster. As such, I wouldn't recommend it as general usage vise; but a blacksmith bending, drifting and hammering vise; sure. As a base I welded it Very thick plates; and now I use it to clamp stuff and hammer; or a adjustable swage block to punch holes. Maybe somebody can get ideas from this fix; there are a few "hacks" in this one

-

Replacing screw/box with parts from a scissor jack

BartW replied to Justor JeiGallo's topic in Vises

I wouldnt weld it. Chance of brittleness is too high. Well... with my welding skills at least: D I had a similar problem once, and i fixed it with a m20 screw box, a piece of pipe to protect the threads and a key to build this: the bar was made from another piece of m20 wire Rod and 2 nuts . The box and front part and salvaged from a truck spare part mounting. -

I though about it for a while, and I have heard a lot of different theories. I usually aim for knucle-height; but I have others lower and higher depending on what work you are doing. Usually it's my back that notifies me after a couple heats it's too low for this task; or the bad hammer control and low power if it's too high for a task

-

Well it was more of a outdoor fair scenario dozens of years ago, with lots of people hammering on lotsa a things... I'm not sure a lot of "teaching" was happening. The reason I remember well is I was talking to one of the "smiths" and I tell him that those guys over there with sledgehammers look like an accident waiting to happen. He turns his head, open his mouth to say something and before he does; "pling", the top face cracks open. A half-moon shaped section of anvil face fell to the dirt floor. The dude goes "*curse-word* ... Sigh.... " and walks over there. Memorabel moment, and so much wrong going on in one picture...

-

Well; In beginner courses, I've seen a 100 pound vulcan destroyed using sledges & beginners. And I mean half moon cut-outs in the thin faceplate on both sides, so the plate on top is almost cut in half. So big hammers and vulcan's is a no-go if you can miss. However is it better than half the weight higher quality anvil? Yes long term; but single use .... I don't think so. Vulcan's aren't that bad, and they won't give you a headache from the high-pitch sound. They just have a thin faceplate. All my "work" anvils are way bigger (300, 430 and 700 pounds) and way higher quality (cast tool steel; HRC 60 ). These days I leave the beginners whale on the 430 pound skoda anvil; it has rounded edges and it eats sledgehammer faces If you are nervous hitting something; don't. steel shards flying around is always a bad idea. Get something in simple iron like a striking anvil, and don't bother with dings.

-

Hello; I live in Belgium, very close to Herstal; and I've been through the old (and new) gun workshop places. They have lot's of anvils, but all were flat. For making barrels they have huge swage blocks; and power hammer dies the size of anvils with different rounds in them. I've never seen an anvil with a halfround cut-out in the surface. All barrel making is done with power hammers making the huge blocks of twisted steel; making that round and then over to a lathe. I do have another theory... what if it was a cutout for anvil blocks; like a power hammer die fixture ? They were fairly common; and if that shape get's worn out; they may have ground it to a half-round ? Belgian anvils have very distinctive feet actually (wide and relatively flat); have a look at UAT anvils. To me this one seems more german like the S&H anvils.

-

Should I get a training anvil for blacksmithing?

BartW replied to SupaConducta's topic in Anvils, Swage Blocks, and Mandrels

A week ago, I found a young kids who wanted to get into blacksmithing. He had pretty much excactly the same question as you have. What to get to start, and do I need a real anvil (and what if I damage it.. ) ? I gave him this thing described here: I still have a couple bars of those left, and the ones I gave way to get people started have all been fairly popular. Some use them on the side; some use the flat face .... some use it as a swage block or a bolster plat once they upgrade to a real anvil. -

Hello; No, they were pretty much cast as you see them. The feet do have an odd shape with the 4 huge halfround holes; but I've seen stands for these anvils which came from the machine shop of a marine ship which used these holes to grab and secure the anvil. With a boat rolling in the waves, I don't think you'd want an anvil to come off it's stand Makes sense too, given they were Cast in the Czech region under Nazi occupation up untill the 1970'ies by the steel plant which made battleship parts & other large castings.

-