-

Posts

124 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by gmbobnick

-

There is something missing at the end of that feller's statement. ...and let me bask in the glory of being his teacher with minimal effort on my part. With an attitude like that, one might conclude this teacher would never make a good teacher. However, I would give him a chance if he'd see his prejudice. A fitting analogy is the smith who discards a funky, bent up piece of scrap steel with the epithet "it'll never make art". We all know those who can see past the ugliness and bring the beauty out.

-

I saw the Damascus hammer you made in Member Projects. It deserves something special for a handle. I suggest taking a look at sycamore. It has a beautiful stippled grain pattern, is tough and hard to split. Should work fine in your application (small hammer) and compliment the Damascus steel interestingly. I have a piece I have been saving for a knife handle, and thought about it when reading your post.

-

Could a guy just use a 12v battery in line with the charger, or maybe the battery by itself?

-

Where to get square/round stock

gmbobnick replied to Pr3ssure's topic in Blacksmithing, General Discussion

It is a bad idea. However, if you don't have an angle grinder, but do have a hand-held circular saw, you can put a 7" Abrasive Blade for metals on it for a couple bucks. If you are just occasionally cutting off small bars (say 3/4" or less) this isn't a bad way to go. It would be a good idea to find a fair used saw to dedicate to that purpose though. -

What did you do in the shop today?

gmbobnick replied to Mark Ling's topic in Blacksmithing, General Discussion

Thank you Daswulf. -

What did you do in the shop today?

gmbobnick replied to Mark Ling's topic in Blacksmithing, General Discussion

Finally got a couple hours in the shop. Made a bottle opener....yeah, just for the halibut. Gave a try at the ubiquitous leaf key fob, and also a hoof pick. -

What did you do in the shop today?

gmbobnick replied to Mark Ling's topic in Blacksmithing, General Discussion

An elegant knife JHCC. And a lucky friend. -

I think you nailed it. This knife looks like something Arnold might have swiped off the alien in the movie "Predator". Much creative and original thought you put into this.

-

Pulled pork? Well perhaps more like making a silk purse of a sow's ear I think. Nice job Joel. I cant afford the meat to fill that thing and still support my blacksmithing habit. I would probably just have enormous blow-out parties and then suffer the financial consequences. I am thinking of something more stationary and smaller for my purposes and to keep the peace.

-

Frosty the way you described this makes perfect sense and I truly believe bumps me well done the learning path. I messed with my screened coal last night and that alone made a huge difference in the time I got up to good forging heat. Cant wait to try your suggestions. Thanks very much sir!

-

Well Lou here it is, the end of summer. For now I like the gas forge because it suits my short sessions in the shop better and not so risky igniting the crispy cheatgrass by my shop with a coal fire spark. I was having a problem getting coal up to heat quickly , which I may have solved...I think. My coal has about 50% sand sized and smaller in it....really dusty. I think this impedes the air flow through the fuel. I screened a 5-gallon pail full and now that we are past the dry summer conditions I will resume using the coal forge. My opinion may change, but I see advantages in both forge types and will continue to use both.

-

Glenn this is incredibly informative. Thanks very much for taking the time to write this!

-

Aus, I found this moose shed this weekend and thought of you. This is close to a perfect example of a mature moose antler. Shiras moose here in Wyoming. They grow a bit bigger up in Frosty's country.

-

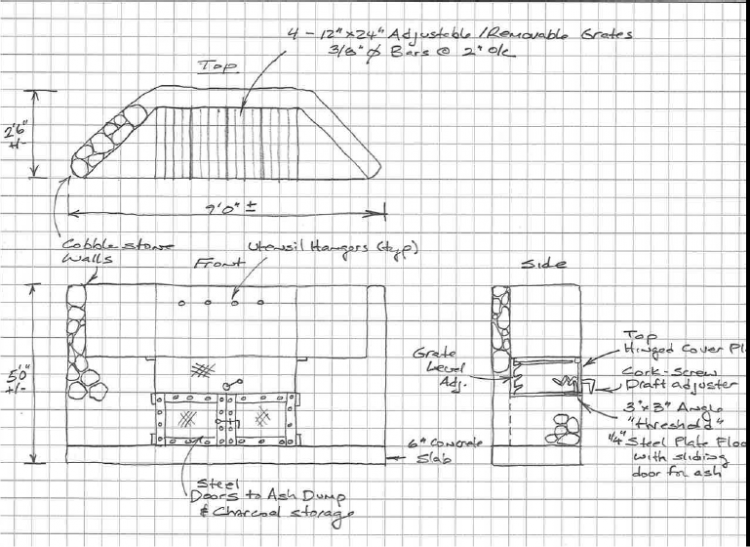

As a group I suppose most who are attracted to fire as a means to create would include cooking in their list of activities. Indeed cooking utensils (squirrel cookers, steak turners, carving knives etc.) have shown up frequently in projects that have been posted. In the spirit of both forging and cooking, I bring a request to the membership. Please share your ideas about desirable/unique/special or just plain cool features, that might be produced via hammer, forge and anvil for an outdoor cooking/grilling station. My project for next summer will be such a station. I love to grill but I also use dutch ovens and cook the usual way but on a bed of hot coals. Here is a sketch of what I initially had in mind to build. Please share any related ideas you are willing to, because it may not be only about my plan but others here as well. Thanks for your input.

-

Ausfire that is very clever. I like your twist on a horse shoe for a coat hook as well. I would lay the horns a bit flatter and swept back some

-

For a guy with the ability to spot a Packard hubcap in a scrap yard, I am thinking your scrap pile might be as interesting as the shop itself. Perhaps I can have a tour when I am down your way.

-

What did you do in the shop today?

gmbobnick replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks Ausfire! I only had a bottle of stout my wife keeps for cooking...which went pfft upon testing. Uh oh. -

What did you do in the shop today?

gmbobnick replied to Mark Ling's topic in Blacksmithing, General Discussion

-

Non, nous avons reconnu l'asperge If this means no asparagus then that don't bother me none...makes my pee stink anyway

-

Are we talking forging or foraging. For the latter I prefer a simple butter glaze on asparagus or broccoli.

-

Forging asparagus seems like it would make more sense. Would rebar make a good steel for that?

-

Is it a bird? Is it a plane? Nope, just an anvil....assisted in flight by a handful of ignited black powder as observed at "Gold Rush Days" in South Pass City, Wyoming last weekend.

-

Took me a minute to spell out “OP” and conclude that I was not to be offended. Thanks for your input! I bought 3/8 and 5/8 v-bolt, 1x5/16 box, small wolf jaw and scrolling tongs. I have been using the box jaw some and see their limitations but also their benefits. Because I find 1” (by about ¼ or 3/8) stock so versatile and useful for many simple beginning projects, I still think they make a good addition to the set, particularly when working with pieces that are really short and need good control for touch-up, decorative marking etc. However, I do believe the flat jaw could frequently replace them. I am slowly working on making a set of flats for comparison. Of the v-bolts, the 5/8 seems more useful to me than 3/8. It handles ½ round ok, which I use a lot as well, and as was mentioned are ideal for RR spikes. I use these the most of all the tongs I bought so far. The wolf jaws seem like they should be more useful, but I am using them mainly for pickup tongs. I find that I do need pickup tongs, so still no regrets. I have not used the scrolling tongs yet, just because of the projects I have been doing lately. But I had a set of long nose pliers I rounded for that purpose previously and they were too weak. I think these will do much better when I get back into scrolls. In summary, if you are just starting out I would say try and limit your material to 3/8 thick or less rectangular bars, and round or square less than 5/8. These are cheap to buy as new mild steel, and common as scrap. These are small enough so inefficient hammering isn’t punished too bad, and you can learn an awful lot with that material. Then with ½ or 5/8 v-bolt and either 1/4 flat or box jaw, plus a set of pickup tongs you will get well down the road of learning a good long ways before feeling the need to add tongs.

-

Thanks for sharing that story, That's one of probably many old metal craft specialties that I would not have readily thought about.

-

What did you do in the shop today?

gmbobnick replied to Mark Ling's topic in Blacksmithing, General Discussion

Made a David Kailey style guillotine fuller. Used a brush hog blade instead of leaf spring because that is what I had. ...and wouldn't you know some blockhead had to mess with the new tool before the safety briefing.