-

Posts

3,618 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by TWISTEDWILLOW

-

Floor options for shed wooden floor

TWISTEDWILLOW replied to MarriedWithAnvils's topic in Building, Designing a Shop

Could you use the inside of the the shed for power tools and machines you have and use it for finishing work and then build a lean to off the side of the building to set up your forge and do all your hot work under the lean to? -

I’ve got a vise vice and I’ve dragged home quite a few but I’ve never come across anything like that one it’s pretty cool, curious how wide are the jaws? Sorry I’m like frosty I can’t help with info either on the vise or cart but they are both really sweet finds.

-

Doing more research in my area I found where a cable suspension bridge used to pass over the baron fork creek almost a century ago. No real way to tell if this vise was used for that project but that’s the only cable bridge I can find that was around around here. We have some 100 year old bridges still standing an in use but they aren’t cable.

-

JLP Blacksmith Teaching Center.

TWISTEDWILLOW replied to jlpservicesinc's topic in Building, Designing a Shop

Glad to hear you got your problem figured out and was able to bring it back online -

Mouse Hole Forge Anvil ID

TWISTEDWILLOW replied to Shane V's topic in Anvils, Swage Blocks, and Mandrels

That’s a nice find Shane -

What I found interesting is that his company was involved In everything from several famous bridges to military equipment to Lindbergh’s plane!

-

Lol that’s a good idea frosty, Thomas don’t worry I keep up to date on my tetanus shots because every were I go I’m digging through junk piles, billy and pnut it’s not that I actually buy pbr on the regular it was just the cheapest beer I could find that day lol.

-

JLP Blacksmith Teaching Center.

TWISTEDWILLOW replied to jlpservicesinc's topic in Building, Designing a Shop

It’s a really neat project and I hope you find your wiring issues without to much trouble or frozen fingers, I can’t wait to see your machine up and running again! You already got wheels turning in my mind about making something like that for my shop. -

Show me your anvil stands

TWISTEDWILLOW replied to pkrankow's topic in Stands for Anvils, Swage Blocks, etc

That looks really nice! -

JLP Blacksmith Teaching Center.

TWISTEDWILLOW replied to jlpservicesinc's topic in Building, Designing a Shop

I’m not an electrician or a hvac guy but Im wondering What if you returned the wiring back to its original set up when it was working and see if it does work agin then put your kill switch on the supply line? Also does it have any thermistors, thermocouples or fuses that might have blown like on a dryer? I know a dryer motor will still spin but if one of those things blows then the dryer won’t heat. If it does have one of those you could test them with your multimeter set on ohms and rule them out as a problem. Sorry I’m not much help. -

JLP Blacksmith Teaching Center.

TWISTEDWILLOW replied to jlpservicesinc's topic in Building, Designing a Shop

That’s a pretty cool heater, now I want one! -

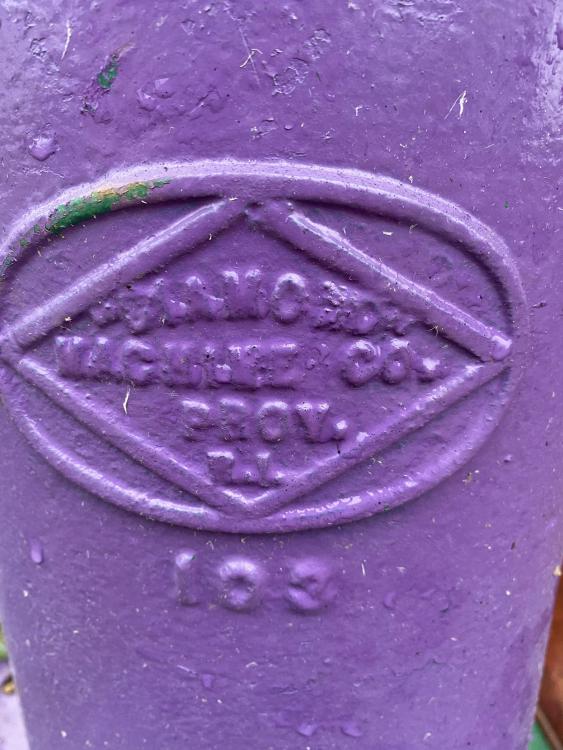

Here’s another one of my junkyard finds, i guesstimate it to be 175 to 200 pounds but my wife has banned me from using her bathroom scale to weigh dirty rusty junk I drag home so I’ll have to get a weight later for it. The searching I’ve done so far has led me to it being a wire rope eye splicing vise. The company that made it turned out to have a pretty interesting history but I was unable to find any info on when it was made. It has three jaws and two move at the same time. I haven’t found a use for this thing yet but it was weird and I didn’t already have one so of course I needed it.

-

Show me your anvil stands

TWISTEDWILLOW replied to pkrankow's topic in Stands for Anvils, Swage Blocks, etc

Andrew, If you can’t mount it permanently maybe you could find a piece of plate and mount it to that to help keep it from spreading out like Jennifer suggested. You could drill and tap the holes and put the bolts in from the top so it will set flush. you could still have it mobile that way and maybe take some of the stress off. I think everyone here is just worried about the cast iron failing and dropping and anvil on your foot. -

Show me your anvil stands

TWISTEDWILLOW replied to pkrankow's topic in Stands for Anvils, Swage Blocks, etc

My vote is also cast iron I’ve got an old cream separator out in my junk pile with a stand similar to that one and i believe mine is cast iron. Neat old stand I just haven’t figured out what to use mine for yet. -

My Silver drill press.

TWISTEDWILLOW replied to Jim Foster's topic in Drills, Post drills, Mag drills, etc

that’s a nice silver! I’ve found two just like yours but they were both missing parts or had broken parts and neither looks as nice as yours. I’ve still got one rigged up in the shop that I use but it’s not near as complete as that one. -

If you get it I’d be really interested to hear if it is a green river foot vise. I’ve been hunting for one for several years now but when I find them they are either to far away for me to get them or they are higher than I I wanna pay. So I just keep hunting I figure one day one will turn up we’re I least expect it. Did you get the swage block that’s setting buy the fire pot? Also that cone looks really sweet how tall is it and what’s the top and bottom diameters? Sorry for all the questions I get excited when I see a pile of old rusty tools.

-

I zoomed in and got a screen shot of it. It really looks like the top end of a foot vise but I could be wrong. Thank you for the info on the shops out west of me I’ve got some kin out their that may know something I’ll sniff around and see if anyone has ever heard of what happened that stuff at tinker. Are those post drills champions?

-

And here I thought I was dragging home lots of rusty gold. Looks like you hit the mother load in one trip. I’ve filled up my truck a time or two but I never found that much stuff in one place at one time or if I did I couldn’t swing it money wise. I seen lots of goodies when I zoomed in the pictures but one thing caught my eye in your fist picture left side middle is that a green river foot vise that I spy or are my eyes deceiving me?

-

Wow that’s a cool story and it kinda makes me wonder every time I here about something like that, how many old warehouses, closed down hardware stores, barns and surplus sites still have vintage tools and machines new In the box that have been forgotten and looked over for decades. This is why I like exploring and following stories and leads sometimes it’s nothing but waste of time and gas and sometimes there’s a goldmine of forgotten history setting in the back of a dusty old building. Here’s some pictures of a couple of things I dragged out of that salvage yard before it closed.

-

Thank you Steve, i thought it was cool that it still had the matching base with it when I found it because most of these grinders I’ve seen don’t have a base with them. Thomas those are really cool I saw one built like your larger one in a local salvage yard, they had it in the shop hooked up to a 5hp electric motor and they had changed it over to run on modern vbelts. It’s nice to see yours both still have the original flat belt pulleys. The salvage yard went out of business and I was late to the auction so I wasn’t able to save a lot of the old tools and machines that were there. They had been open since the early 1940s and I loved going there because you could find almost anything.

-

What did you do in the shop today?

TWISTEDWILLOW replied to Mark Ling's topic in Blacksmithing, General Discussion

I see your point mr powers, I was just curious. -

What did you do in the shop today?

TWISTEDWILLOW replied to Mark Ling's topic in Blacksmithing, General Discussion

Is it possible to take them back apart and then fold them in half to make them thicker? Maybe then they would not have as much flex in them? -

What did you do in the shop today?

TWISTEDWILLOW replied to Mark Ling's topic in Blacksmithing, General Discussion

They kinda look like old lawnmower blades but I could be wrong. -

Here’s one of my older grinders/lawn ornaments. It’s a diamond machine company grinder and matching base. It’s a flat belt drive and pretty heavy I think it was either built for use with in a lineshaft shop or maybe powered off a old tractor pto. I thought if I ever find an old hit and miss engine it would be cool to hook it up but till then it’s just a lawn ornament. The Babbitt bearings seem to be in excellent shape but the one of the stones doesn’t fit correctly on the shaft and I never got around to finding another wheel or building a spacer to help it balance out. Somebody painted over the old machinery green with black an purple but you can see it peeking through in places.