Depuuty

Members-

Posts

19 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Depuuty

-

someone I know works at a factory where they produce prosthetic arms/legs and what not I got this from him AMS / AM5 maybe "I think that's the manufacturer and not pictured on here it says (1250) 1200 series steel or something?

-

If I've learned one thing from this forum everyone has a different taste

-

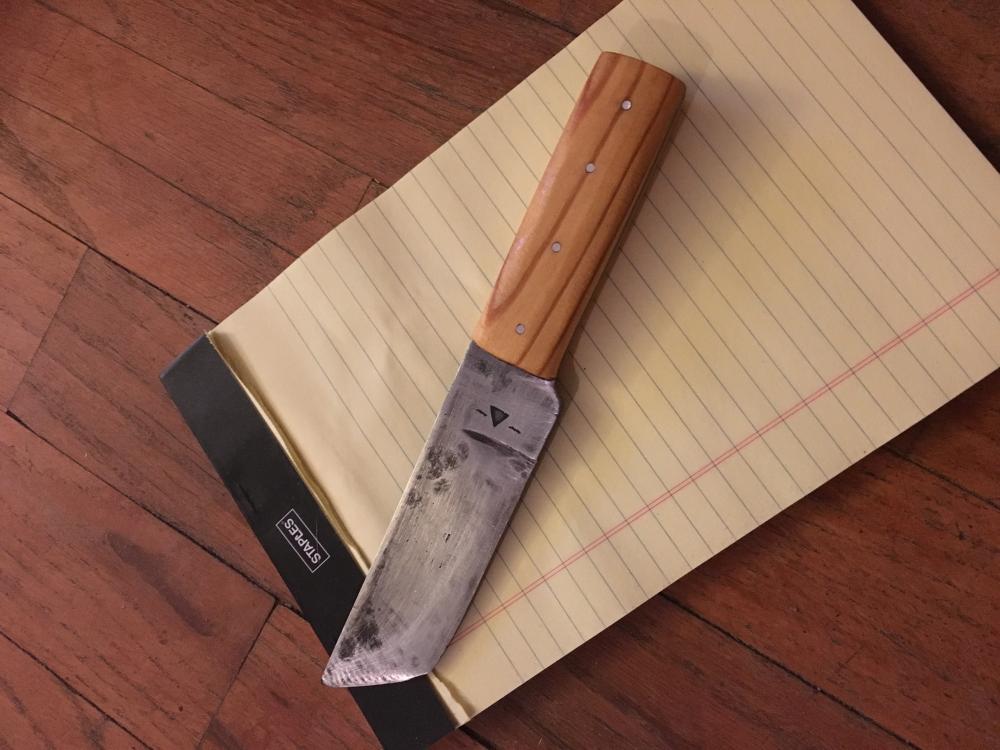

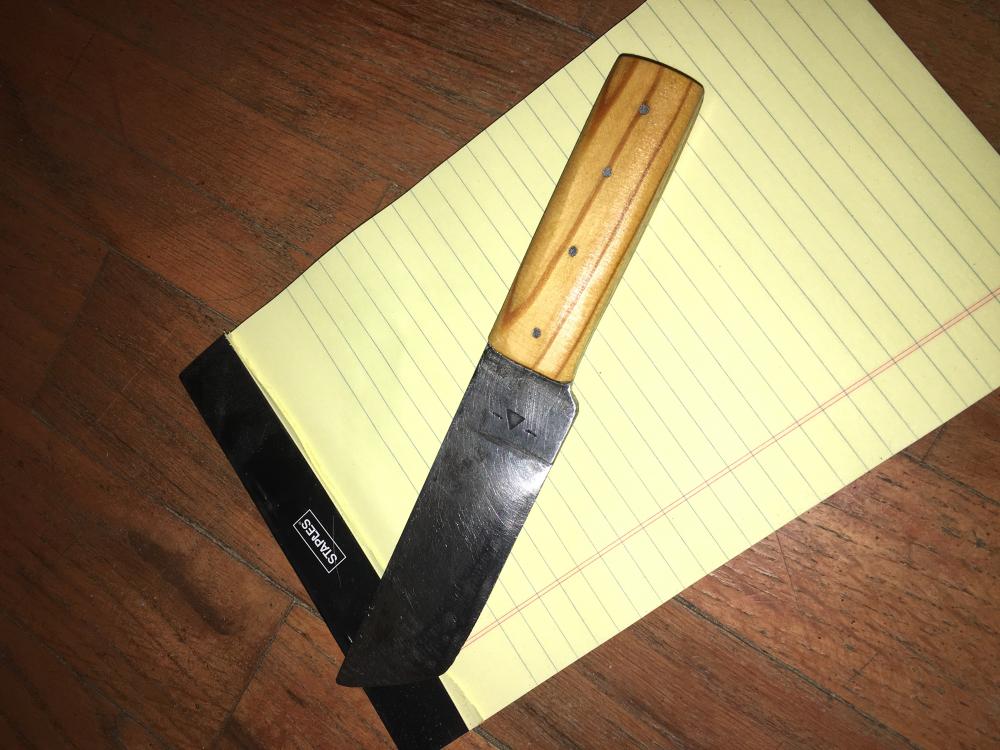

knife |Knife #3| Critics Welcome! (Rate My Knife 1-10)

Depuuty replied to Depuuty's topic in Knife Making

Buddy.. I really do want my blade to look dark like that if I wanted to spiff it up I could the woods definitely not pine I know that and I got it up to non magnetic and quenched in oil then heated up a piece of metal and rested my blade on top of that till I was satisfied -

knife |Knife #3| Critics Welcome! (Rate My Knife 1-10)

Depuuty replied to Depuuty's topic in Knife Making

Once again I appreciate the feedback but I'm afraid I made this knife the way I like it.. Dirty and fat. thanks for looking! I name this knife the "Donald Trump" -

Hello again. As Stated in the Title please Rate My Knife 1-10 It seems I'm getting better with each knife untill I get a belt sander I hand sand and use an angle grinder for most of the leg work. For those who said I should use better steel than rebar on my first knife, I think it's a good idea to use low quality steel when first starting out. The steel is 1095 Wood is unidentifiable to me atleast, just some stuff I had laying around and then polyurethaned Oh and that engraved triangle with the lines is my makers mark I guess using a 12 volt battery some tape and wire to engrave it. advice and criticism always welcomed! etching is not the same as engraving, and the wood looks like pine

-

Not sure what type of steel but I'm pretty sure it's good material wood is pine quenched in oil tempered at 450 for 3 times for 90 mins like i said I'm novice

-

Hello.. let me start off by saying I'm very very amateur. This is my second knife I've ever made Critics welcome!

-

Well i think it's pretty

-

Thanks, thanks! I'm gonna go for a traditional camping knife next.. LET ME SEE YOUR FIRST KNIFE

-

Well boys.. I was told it would not be the best material using rebar, but the anvil did hold up and I believe it will for a little while.. First knife and probably as far as I'll sand this one didn't flatten it out enough for a handle so I'll just learn from this and go on to the next knife Besides buying letter punching tools how could I affectively put my intitals on the handle?

-

-

She isn't pretty, but I'm proud.. Made from 3/8 Rebar not sure what style I was going for, just let the magic happen Doing this on my phone.. Don't have the time to link the "FIRST ANVIL" page.. However if you'd like to see more anvil pictures go to that thread thanks for looking, CRITICISM APPRECIATED

-

I'm going to run the angle grinder on it still The only downside, the steel bar is a little soft and shows some indentation from my hammer.. But not as soft as that anvil from harbor freight. Love harbor freight they just have a bad anvil.

-

In regards to the location thing, I am from Indiana. However I don't know about wanting to be in "visiting" distance, so maybe I'll just keep it at Indiana. I do have an angle grinder but I don't feel I'm skilled enough to shape a horn out of that. The steel is 20lbs, the whole setup I would guesstimate at about 230 and maybe less when it fully drys. That wood glue that I have on there is just for moister really. I wedged that steel in the stump pretty well. Thought about putting some iron strap on there but I don't think it will be needed. I will have an update tomorrow on how well it works for any new smiths out there who want a under 10 dollar anvil. Thanks Frosty

-

Base is made out of 2x4's stacked and a concrete floor. The anvil is some 20lb piece of steel I found at a scrapyard waiting for it to dry and then I'm going to try and swing on it