-

Posts

448 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by templehound

-

Thanks, Joe Clit! I ground the plunge lines as crisp as possible on the flat grinding platen to grit 150, then I ground diagonal(cater corned?)on the contakt wheel along the plunge line with grit 240. In this case it was easy because there was no ricasso or shoulders which to take care of. Slack belt grinding is the enemy of crips plunge lines, so i masked the plunge lines with paper tape(only paper , no plastic tapes) and went to the final convex shaping to sharper geometry on the slack belt. followed by hand sanding. Grinding nice plunge lines is always something that is strongly depending on skills, tools and machines.Every maker has different conditions on all those aspects, so it is very individual how to get the desired result....but I hope this gives some ideas and helps somehow. Cheers

-

-

Just two convex surfaces intersect in the center of the blade's edge, from heel to tip. No advanced details in the grind, neither ricasso nor shoulders like it is on edged tools since hundreds of years. Timeless and as plain as possible with 1.2442 blade, copper ferrule and yellow ironwood handle. Blade measures 90 mm and 215 mm overall length. Cheers

-

Seax?....as far as I know this is a Bowie blade....but You as the creator can call it like You want....nonetheless respectable effort.

-

Steve, Daswulf, Thanks Guys!

-

Köszönöm, Gergely!

-

Since over hundred years in production , the 1.2516(120WV4) is one of the finest steels for tools. Only available in round stock it requires more effort to bring it to a blade.....it is all worth it. Together with 6Al4V Titanium and Acacia mangium root it results in this small folder. As simple as it gets. Cheers

-

Very nice!

-

Tools that pay the bills and feed the mouths...

templehound replied to templehound's topic in Folding Knives

Zrognak, Windancer....Thanks! -

Knife 01 is well made indeed, real fine user!...and the lanyard hole and file work testifies to careful execution. The pictures showing more the embellishments than the blade or a better overall perspective....the angle of view comes only from the rear and that is a pity...that knife deserves better pictures or at least one or two more...Imho....solid leather work too! Knife02 is the kind of flint blade knife art I never cared about so much...looking at art knives I always feel like a simple minded monk.....Not so easy to comment on something that is subjective to personal taste The handle is to square and the guard might look better if it flows into the handle with a radius....but besides it gives a glance of Your creativity and as it demonstrates on the Celtic carving, it is obvious that You are a skilled fellow. Thanks for sharing and keep up the nice work . Cheers

-

Thanks, DuEulear! You will find it here, https://www.iforgeiron.com/topic/54243-the-fortune-cookie/ Thank You, Irondragon!

-

A greeting to from SEA to Massachusetts....Thanks a lot PaperPatched!

-

TwistedCustoms: You are welcome!...I really like the definitions "ghostly and mysterious"...Thanks a lot! Mudman: Thank You!....well, do it, make one.. I learned a lot while making them that archetypal kind of knife contains fun as well as challenge. Daswulf: Thanks for You reply, bro! It is all about appreciation...its the motivation of keeping on posting.

-

Thanks Lou L, You reply is a honor and a pleasure as always This one was more difficult to make because of the small margin on the handle material. So I took the blank of the blade and worked myself to the point where I was sure it would work.

-

...while making them, my good Sony camera had problems due our climate.Sony has excellent Lenses from Zeiss(Germany)but is very sensitive to tropical climate. So I had to resort on my replacement camera from Samsung which is much more reliable in humid climate but the difference in lens quality is enormous. But I hope the difference does not diminish the pleasure of looking too much.

-

They were born and went their ways. Maybe You Guys like to have a look on them. They are made of cold work Tungsteen tool steel(as always) and handles are made from buffalo leather and bone. Cheers

-

Hard to tell, what You can do better, because the critiques that I maybe have are all about taste and personal preferences.....I like the knife with the wood handle much more because it is not so Spyderco-like as the other one and has a more beautiful blade shape......but as I said, very personal. What is most important to me are the edges of both blades....both knives have very nice edges and very accurate points....very well made!

-

Tough there is a difference between rigidly fixed blades in a machine and free hand led blades. ....the cutting test machine gives information about wearing resistance of the alloy / the steel...for precise non-dynamic cutting action but blades that are hold and used free hand experiencing a lot of different angles and stresses on the edge. It says very little about edge performance of hand knives, the knives we are dealing with the most Altough interesting.... Thanks for sharing!

-

What pin material to use on Damascus bolsters

templehound replied to Aaron Gouge's topic in Knife Making

Thats a good one. I did this several times. Needs a bit patience to get it in precise on diameter. cross wise the steel etches a bit deeper, faster....but that blends the most -

Thanks for the explanation, Steve

-

What?.....because of cleaning amounts You switched to water hardened steels?.....or what does it mean ..."to kick the oil bucket"? this is to me like, my car is covered with dirt so I decide to switch to walk on foot.... .,.....but what is the motivation and what are the expectations of Your knife making?....stay clean rather than worry about quality ? please excuse my frank thoughts....why dont You try stone hand axes or bone knives.....making them must be a much cleaner event without any oil, water and heat treating at all maybe I understand it completely wrong....linguistic difficulties are possible....in any case, no offence....with all due respect and humor ....

-

Nice bunch of bush swords!.... I bet that cut already healed up....that job makes our body and defense system dealing easy with flesh cuts....already itching?

-

Daswulf, Stormcrow, Thanks a lot!

-

Thanks for the fine comments,Guys! I colored with gun blue from Birchwood and Casey.after some time the blue fades and changes in antique grey like its now. the bolsters are pinned with 3mm pins.normally I take 3 pins and press them in a vise. cheers

-

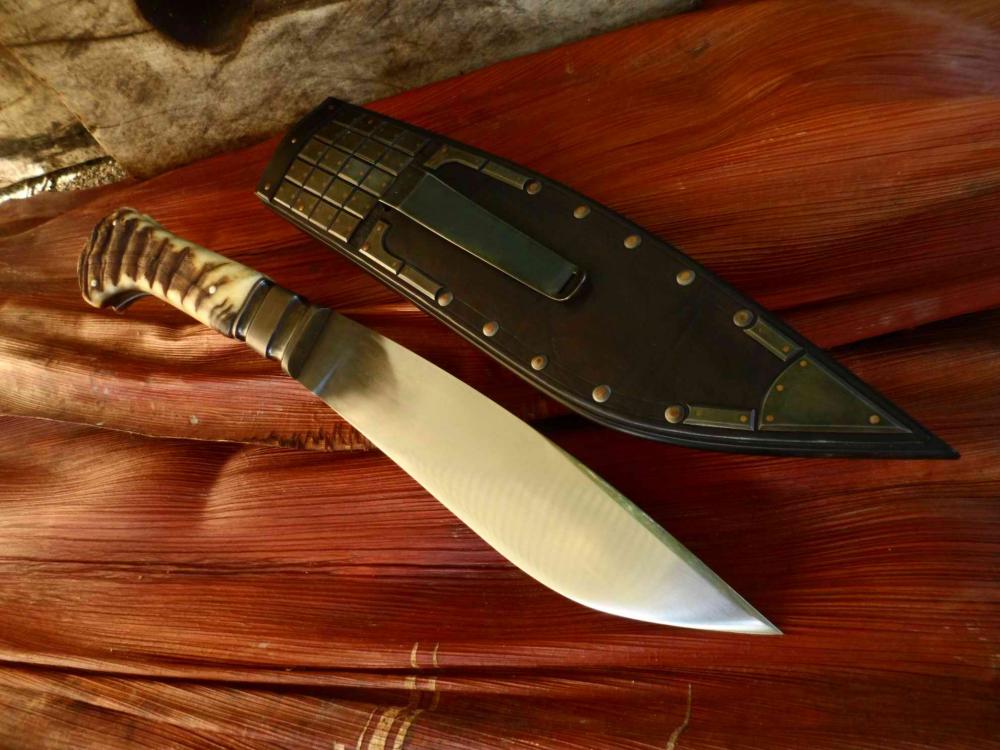

Some kind of ancient warriors belt knife, ....from whatever culture. Blade is 205 mm long and ground from 1.2442 (115W8), bolsters made from mild steel and the scales are rams horn pinned with sterling. Overall length measures 305 mm so because its a warriors knife I wanted the sheath as martial as possible. I armored buffalo raw hide with steel and riveted it togehther with copper.All steel parts are counter riveted from the inside.The two massive liners are made from a single water buffalo horn which had a natural radius that allowed following the blade shape.The throat is also reinforced with buffalo horn bands......at the end it consists of 177 worked parts . Cheers