AnvilAntics

-

Posts

14 -

Joined

-

Last visited

-

Hi Justin,

Welcome fellow Australian. It's always good to see Australians pop up on this site.

I see you are from Ballarat. Been there having a look at Sovereign Hill and the smithy there. Pretty impressive shop.

There's a ghost town in Western Queensland called Ballara. It is said that it was supposed to be Ballarat but the the sign writer ran out of space. So Ballara it is.

-

Have been snooping for many years.

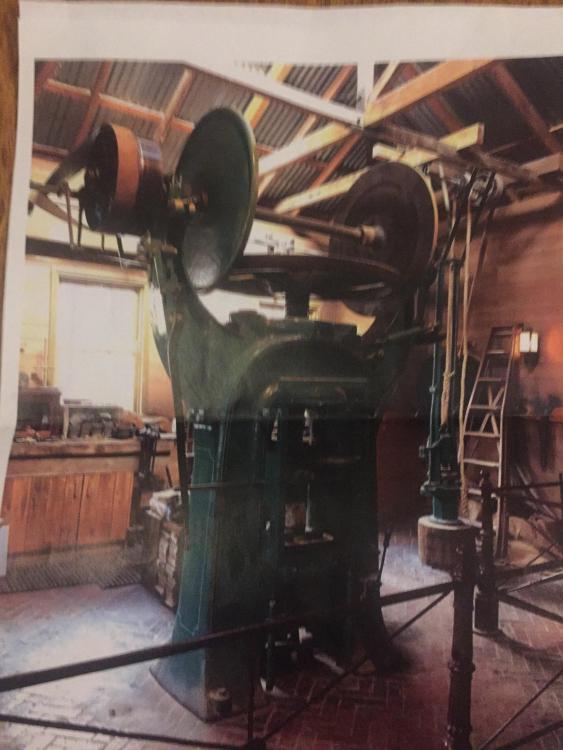

I work at Sovereign Hill in the Wheelwright and Coachbuilding department, we have our own forge up there. All the horse drawn vehicles that we use there are made there. There are some videos of us hot tyring and timber bending on the Sovereign Hill social media page.

You are up north? I have spent some time farm sitting in Jalatten, lovely part of the world

-

Wow! You might be the guy who gave me one of those timber wheel hubs that you make on that machine in the wheelwright building.

Your operation at Sovereign Hill is a lot more commercial than our heritage museum where I have my forge (www.historicvillageherberton) but we have a lot in common. I watched your blacksmith at work making fire tools and was very impressed with the steam set up you have there.

And yes, we are in the far north of the state. I know Julatten well. Just an hour or so north of us on the way down to Port Douglas. Nice bit of country.

-